PDF(5357 KB)

PDF(5357 KB)

PDF(5357 KB)

PDF(5357 KB)

PDF(5357 KB)

PDF(5357 KB)

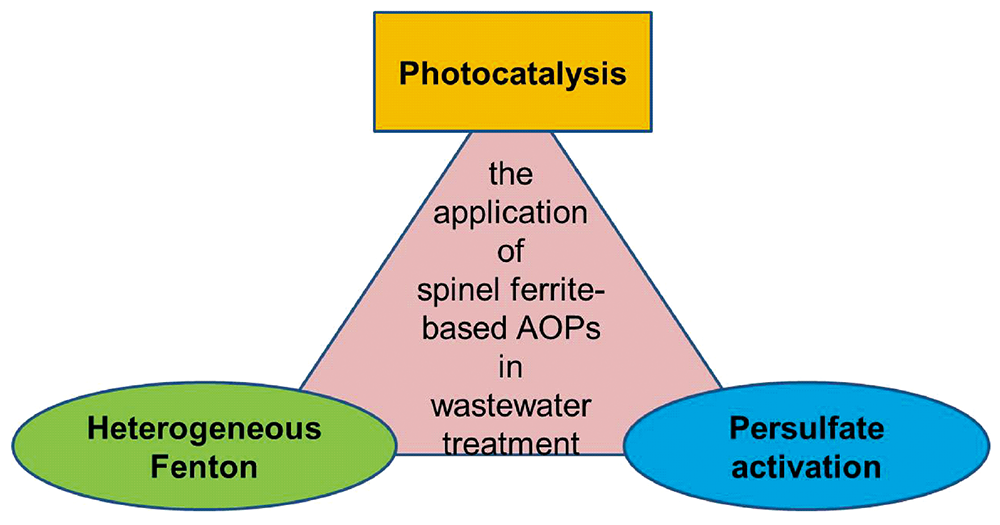

基于尖晶石型铁氧体的高级氧化技术在有机废水处理中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of Spinel Ferrite-Based Advanced Oxidation Processes in Organic Wastewater Treatment

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |