PDF(19776 KB)

PDF(19776 KB)

PDF(19776 KB)

PDF(19776 KB)

PDF(19776 KB)

PDF(19776 KB)

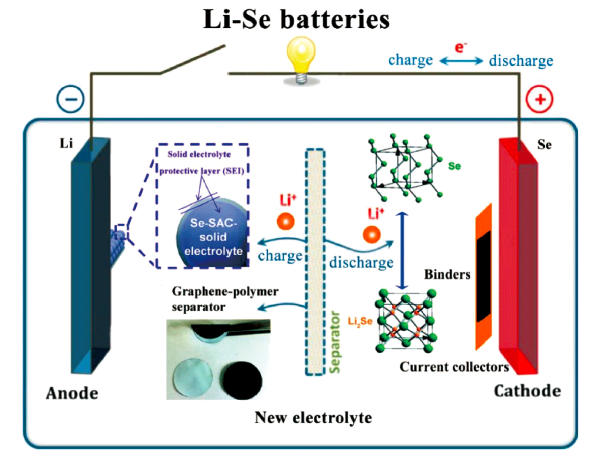

锂硒电池的研究现状与展望

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Research Status and Prospect of Li-Se Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |