PDF(8403 KB)

PDF(8403 KB)

PDF(8403 KB)

PDF(8403 KB)

PDF(8403 KB)

PDF(8403 KB)

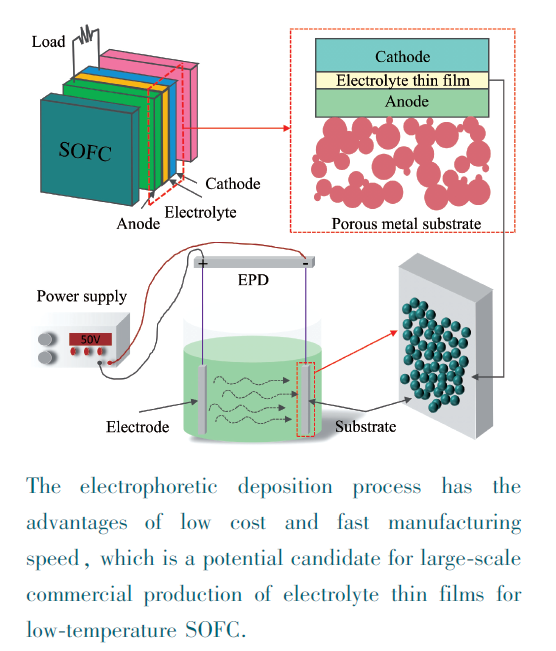

制备固体氧化物燃料电池中电解质薄膜的电泳沉积法

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Electrophoretic Deposition in the Preparation of Electrolyte Thin Films for Solid Oxide Fuel Cells

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |