PDF(2362 KB)

PDF(2362 KB)

石墨烯及氧化石墨烯对分离膜改性的方法、效能和作用机理

王茜, 郭晓燕, 邵怀启, 周启星, 胡万里, 宋晓静

化学进展 ›› 2015, Vol. 27 ›› Issue (10) : 1470-1480.

PDF(2362 KB)

PDF(2362 KB)

PDF(2362 KB)

PDF(2362 KB)

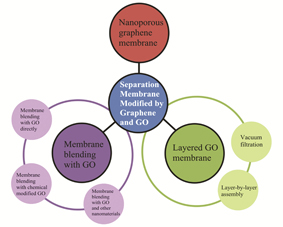

石墨烯及氧化石墨烯对分离膜改性的方法、效能和作用机理

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Methods, Performances and Mechanisms of Separation Membrane Modified by Graphene and Graphene Oxide

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |