PDF(5239 KB)

PDF(5239 KB)

PDF(5239 KB)

PDF(5239 KB)

PDF(5239 KB)

PDF(5239 KB)

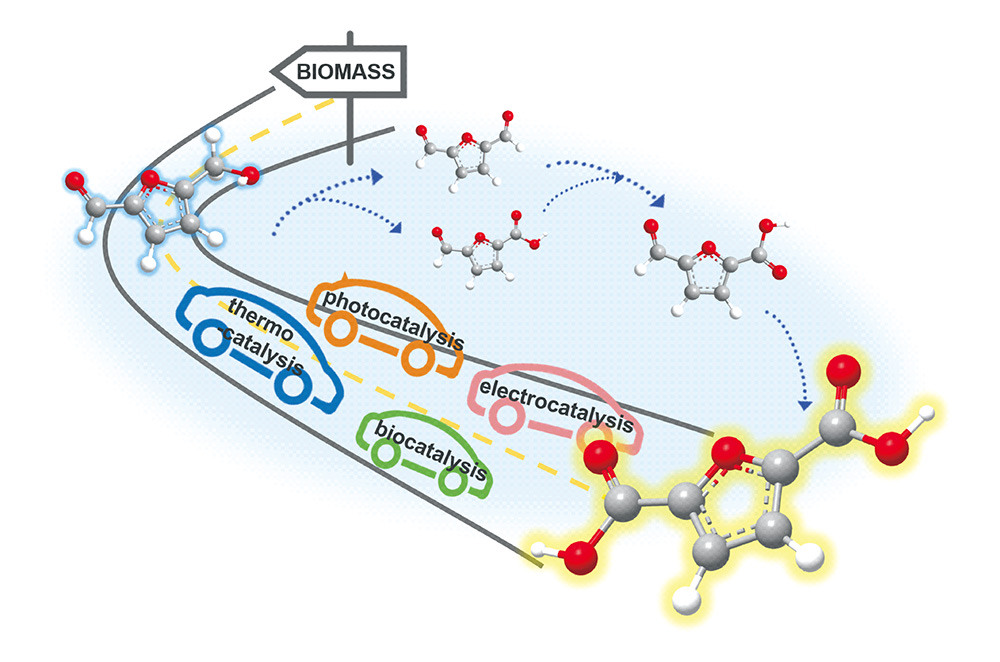

HMF催化合成生物基聚酯单体FDCA

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Selective HMF Oxidation into Bio-Based Polyester Monomer FDCA

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |