PDF(16593 KB)

PDF(16593 KB)

PDF(16593 KB)

PDF(16593 KB)

PDF(16593 KB)

PDF(16593 KB)

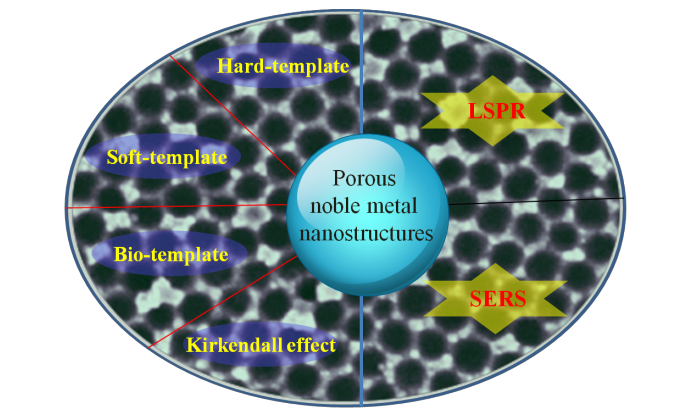

贵金属多孔纳米结构的模板法制备及生物检测应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Template Preparation and Application in Biological Detection of Porous Noble Metal Nanostructures

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |