PDF(14536 KB)

PDF(14536 KB)

PDF(14536 KB)

PDF(14536 KB)

PDF(14536 KB)

PDF(14536 KB)

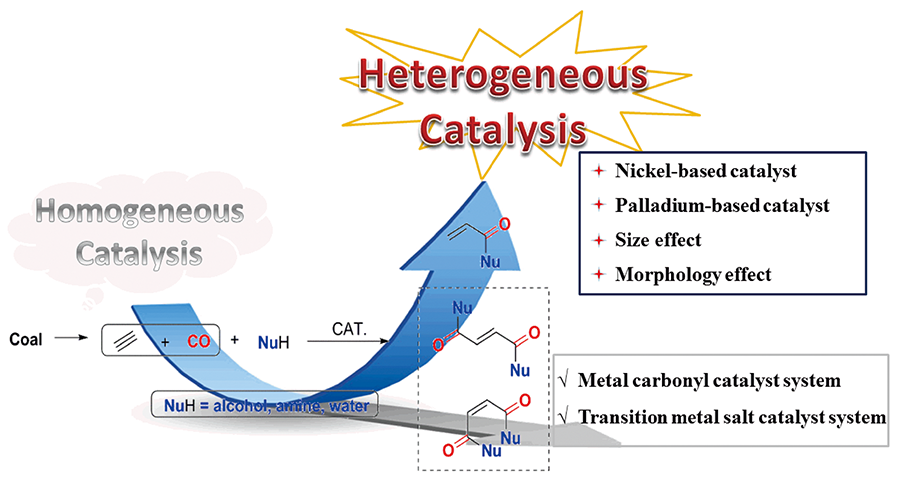

乙炔羰基化反应催化剂:由均相到多相

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Catalyst in Acetylene Carbonylation: From Homogeneous to Heterogeneous

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |