PDF(1616 KB)

PDF(1616 KB)

PDF(1616 KB)

PDF(1616 KB)

PDF(1616 KB)

PDF(1616 KB)

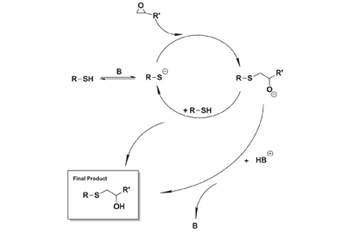

巯基-环氧点击化学及其在高分子材料中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Thiol-Epoxy Click Chemistry and Its Applications in Macromolecular Materials

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |