PDF(17329 KB)

PDF(17329 KB)

PDF(17329 KB)

PDF(17329 KB)

PDF(17329 KB)

PDF(17329 KB)

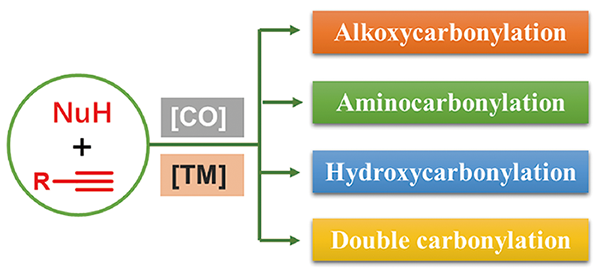

过渡金属配合物催化炔烃和亲核试剂的羰化反应

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Carbonylation of Alkynes with Different Nucleophiles Catalyzed By Transition Metal Complexes

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |