PDF(5661 KB)

PDF(5661 KB)

PDF(5661 KB)

PDF(5661 KB)

PDF(5661 KB)

PDF(5661 KB)

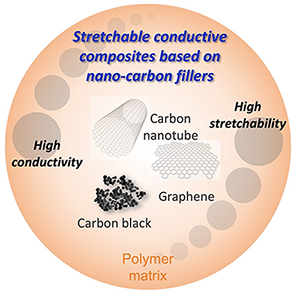

基于纳米碳填料可拉伸导电聚合物复合材料的制备

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Stretchable Conductive Polymer Composites Prepared with Nano-Carbon Fillers

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |