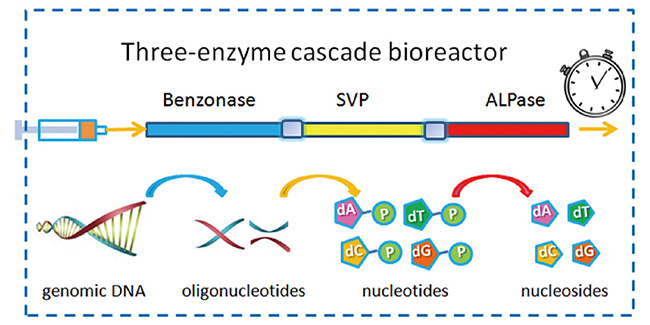

Fig. 2 Schematic illustration of multi-enzyme cascade reaction systems based on the DNA hydrogel[

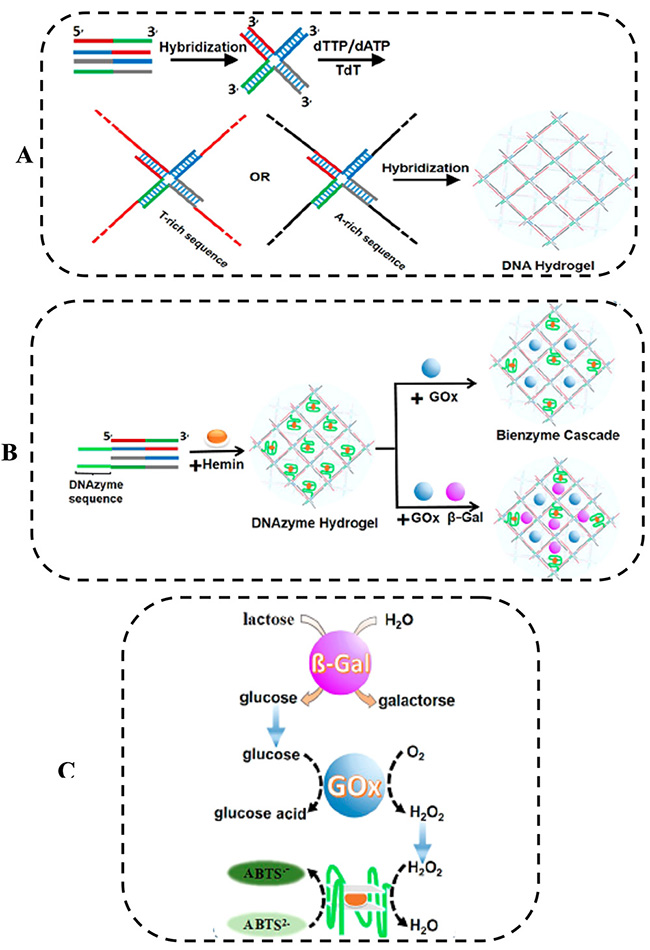

Fig. 2 Schematic illustration of multi-enzyme cascade reaction systems based on the DNA hydrogel[ Fig. 8 Distance-dependent effect of assembled ZS-XR/G-XDH pairs[

Fig. 8 Distance-dependent effect of assembled ZS-XR/G-XDH pairs[ Fig. 10 Schematic illustration of an artificial metabolon confined inside PAA nanochannels to mimic the natural enzyme complex systems[

Fig. 10 Schematic illustration of an artificial metabolon confined inside PAA nanochannels to mimic the natural enzyme complex systems[