PDF(6943 KB)

PDF(6943 KB)

PDF(6943 KB)

PDF(6943 KB)

PDF(6943 KB)

PDF(6943 KB)

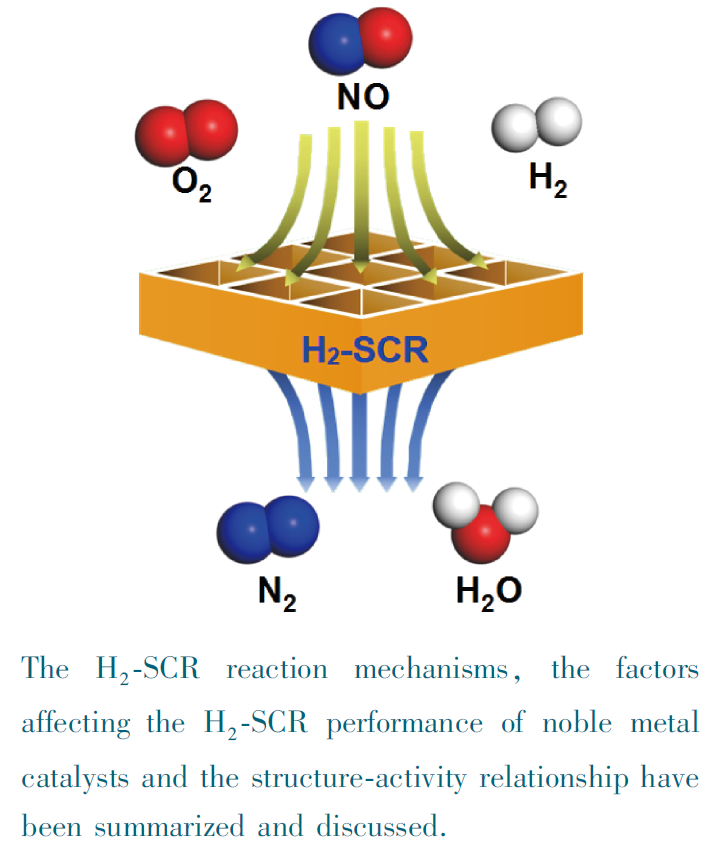

贵金属催化剂上氢气选择性催化还原NOx

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Selective Catalytic Reduction of NOx by Hydrogen over Noble Metal Catalysts

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |