PDF(8164 KB)

PDF(8164 KB)

PDF(8164 KB)

PDF(8164 KB)

PDF(8164 KB)

PDF(8164 KB)

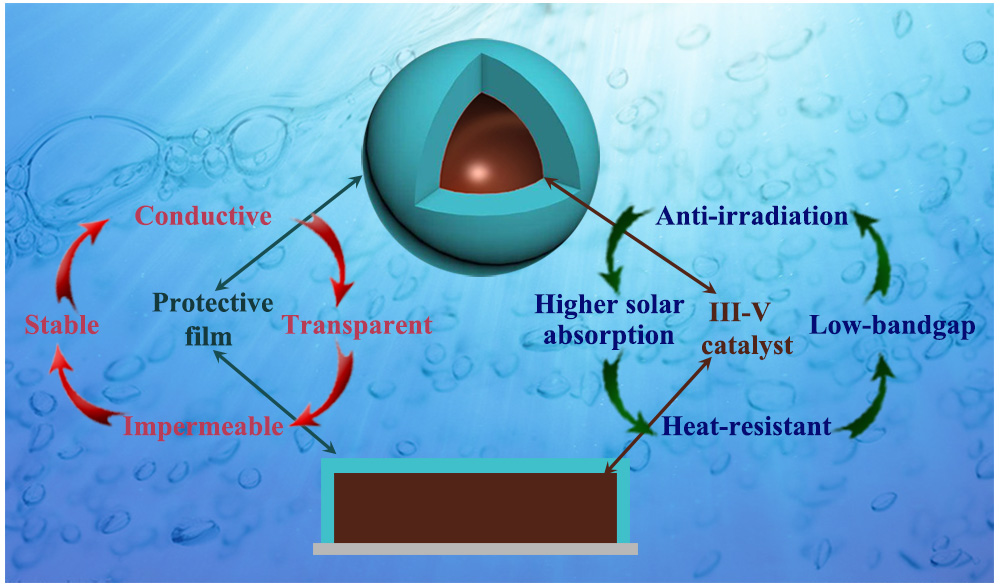

光电催化分解水Ⅲ-Ⅴ族半导体光电极薄膜保护策略

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Thin Film Protection Strategy of Ⅲ-Ⅴ Semiconductor Photoelectrode for Water Splitting

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |