PDF(3707 KB)

PDF(3707 KB)

PDF(3707 KB)

PDF(3707 KB)

PDF(3707 KB)

PDF(3707 KB)

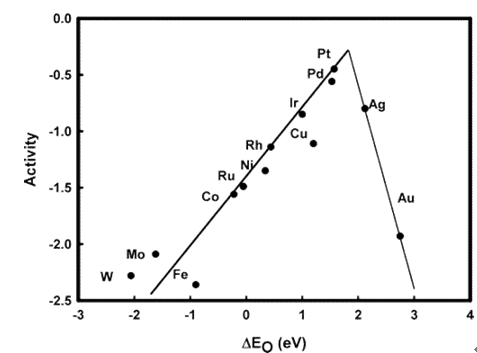

Pt基金属间化合物及其在质子交换膜燃料电池阴极氧还原反应中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Pt-Based Intermetallic Compounds and Their Applications in Cathodic Oxygen Reduction Reaction of Proton Exchange Membrane Fuel Cell

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |