PDF(17831 KB)

PDF(17831 KB)

PDF(17831 KB)

PDF(17831 KB)

PDF(17831 KB)

PDF(17831 KB)

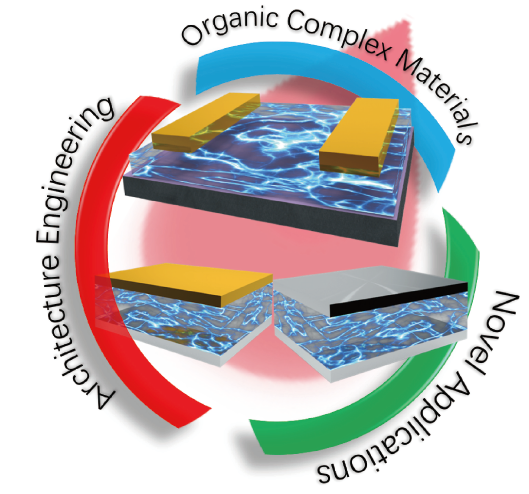

基于有机复合材料的近红外和短波红外光探测器

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Organic Complex Materials and Devices for Near and Shortwave Infrared Photodetection

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |