PDF(1254 KB)

PDF(1254 KB)

PDF(1254 KB)

PDF(1254 KB)

PDF(1254 KB)

PDF(1254 KB)

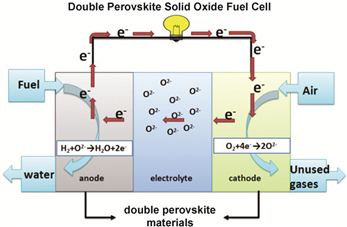

双钙钛矿型电极材料在中低温固体氧化物燃料电池中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Double Perovskite Material as An Electrode for Intermediate-Temperature Solid Oxide Fuel Cells Application

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |