1 引言

1.1 球磨机的类型

表1 震动球磨机、行星球磨机和搅拌球磨机适用情况Table 1 Introduction of mixer ball mill, planetary ball mill, and stir ball mill |

| Mixer ball mill | Planetary ball mill | Stir Ball mill | |

|---|---|---|---|

| Mechanical force | Impact force | Shear force | - |

| Common Brand | Retsch | Fritsch | Outotec HIGMill |

| Invented time | 1923 | 1961 | 1922 |

| Scale | grams | 10~100 grams | More than a ton |

| Application | Inorganic chemistry, organic chemistry | Organic Chemistry | Physical grinding |

1.2 辅助研磨

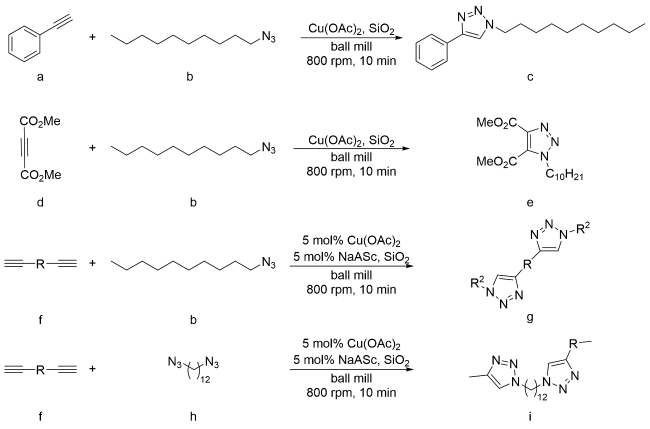

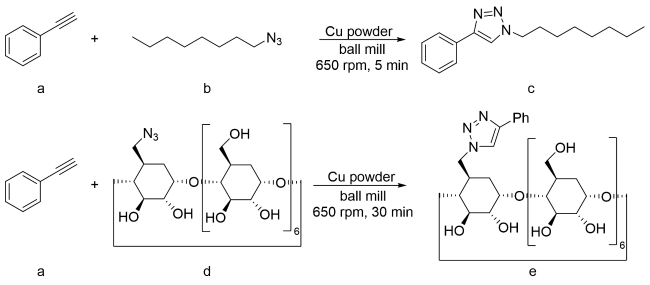

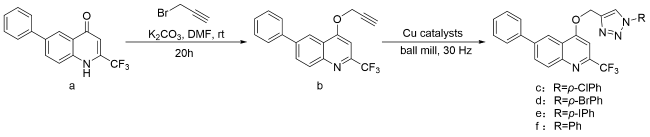

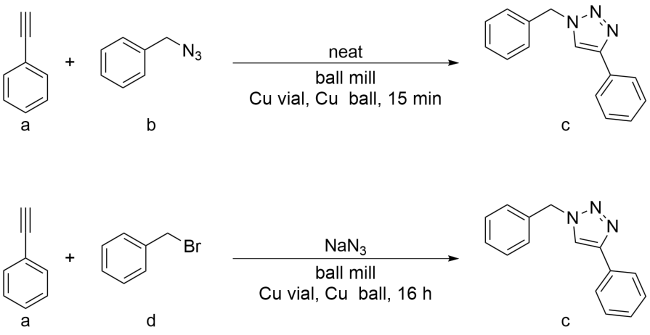

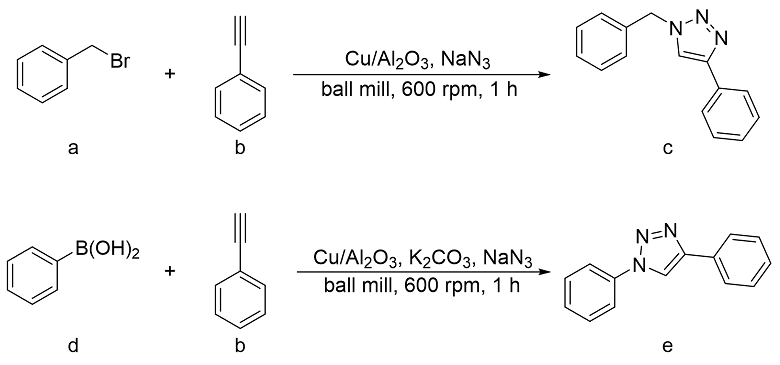

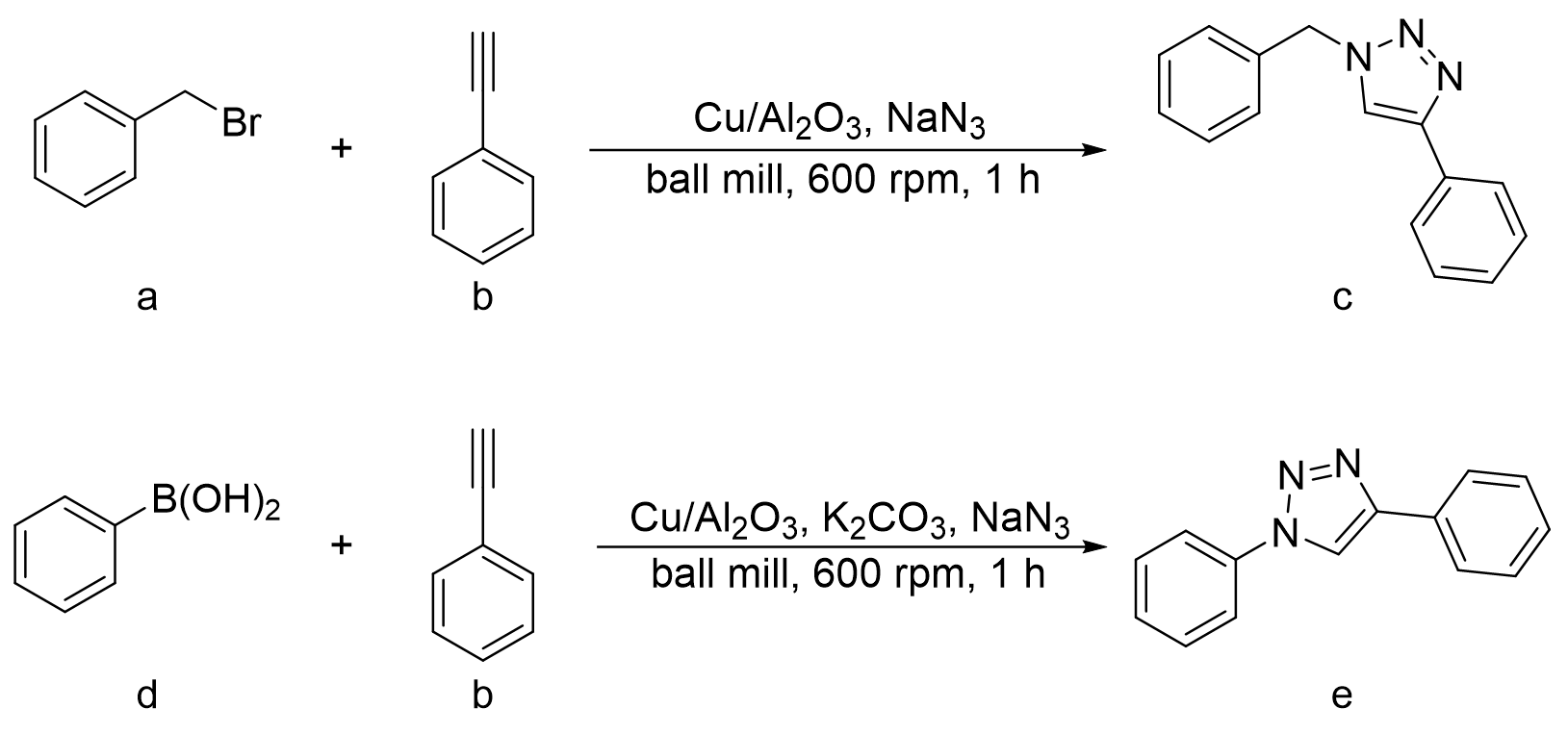

2 球磨实现的点击化学反应

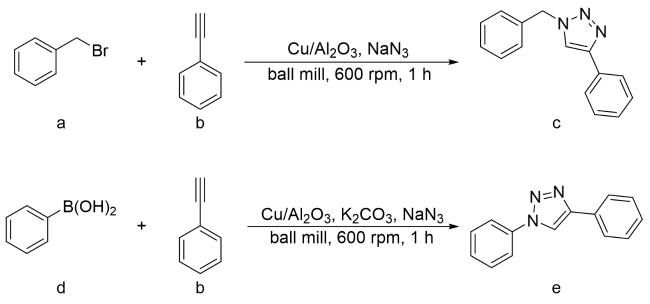

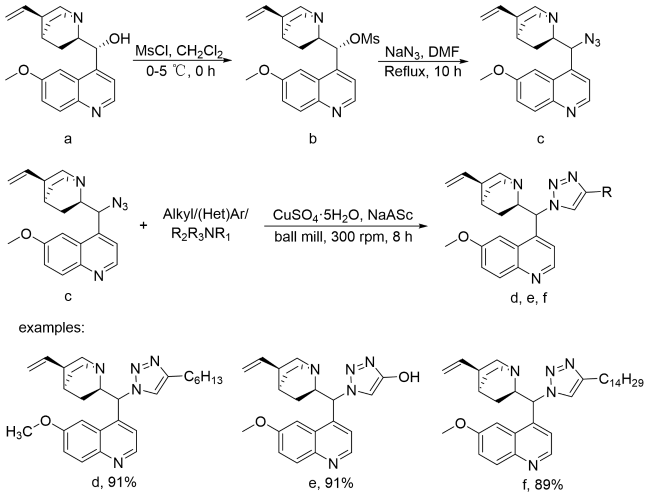

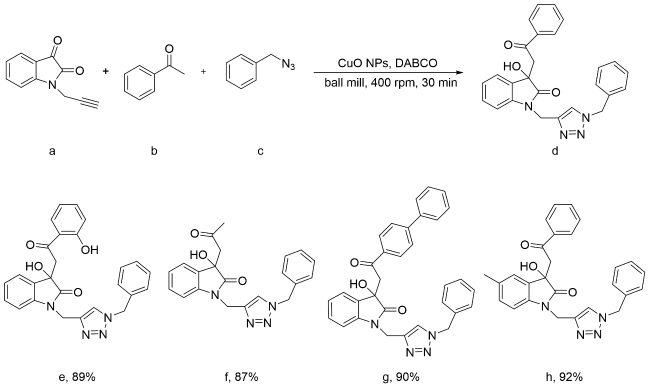

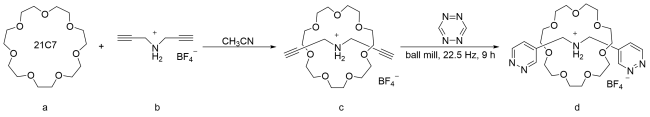

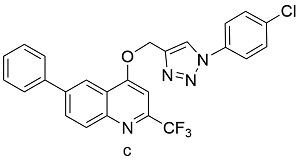

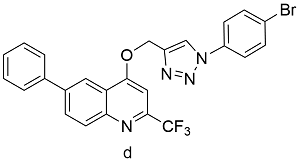

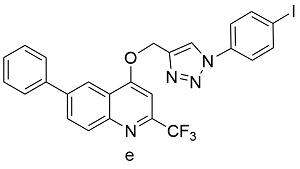

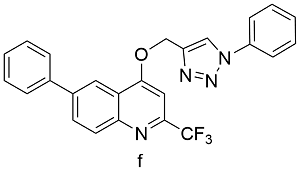

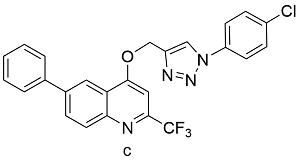

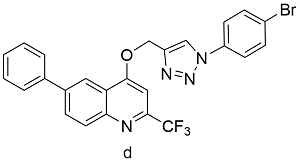

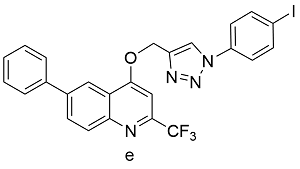

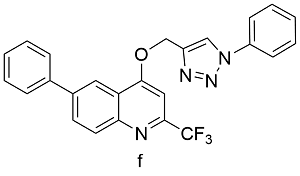

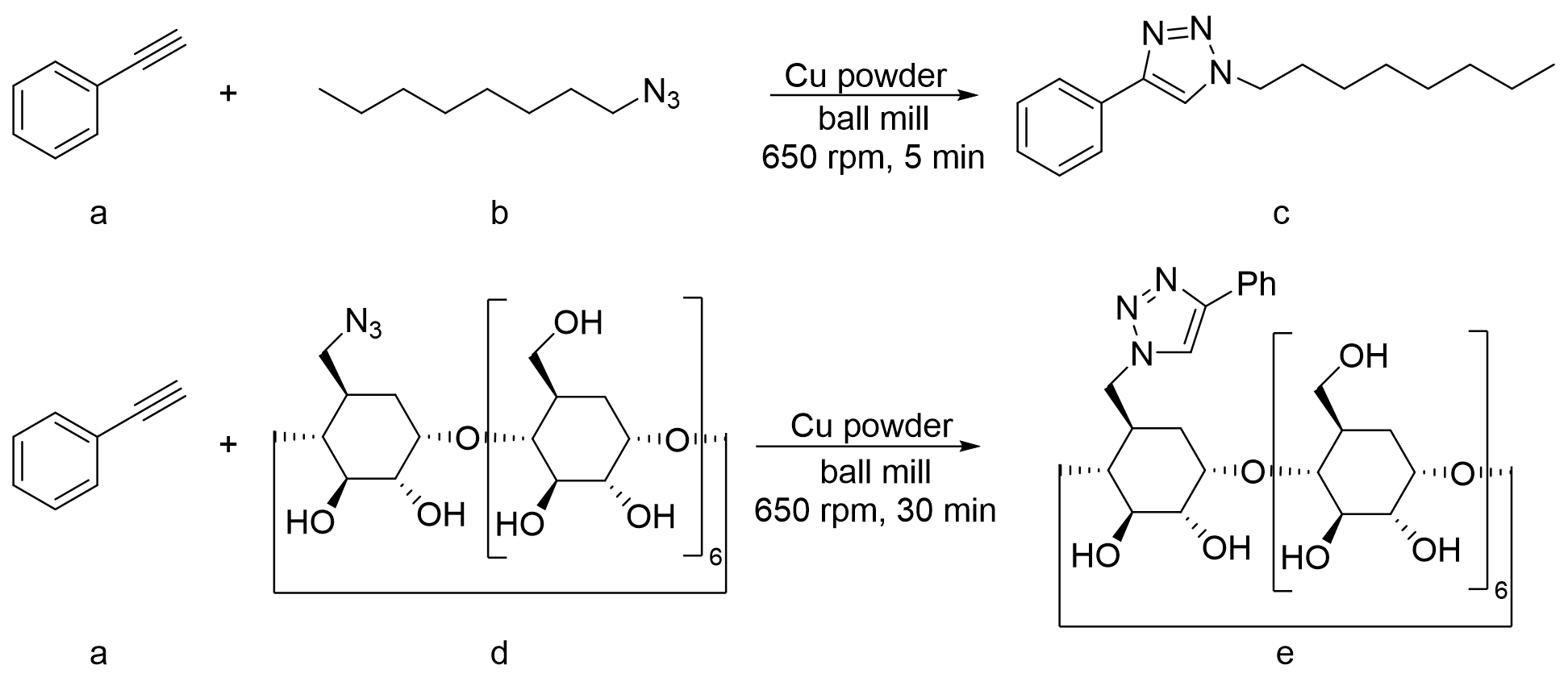

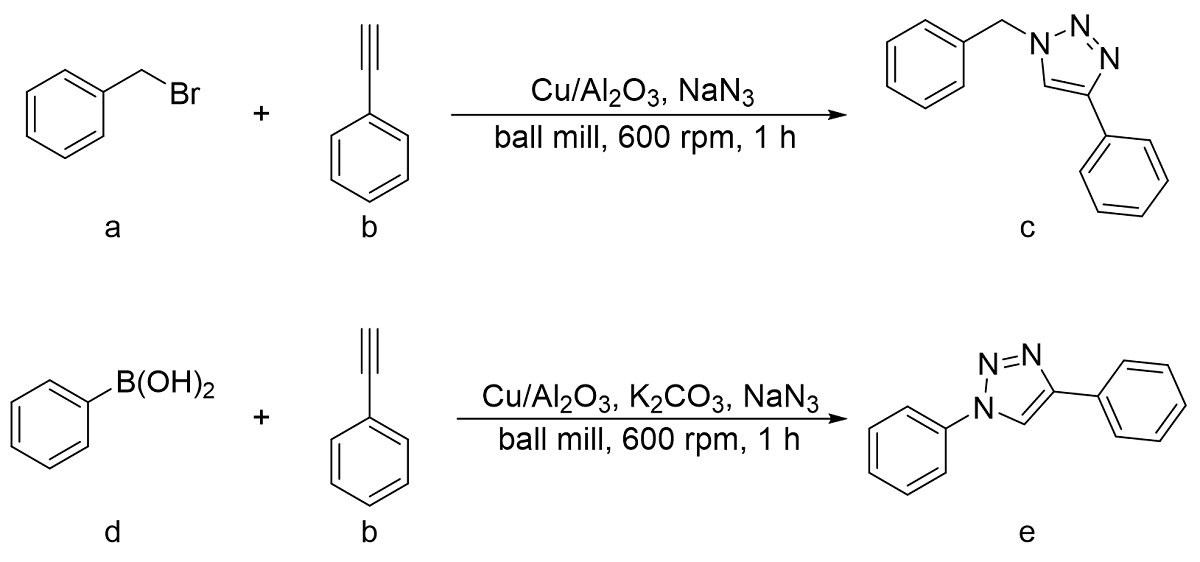

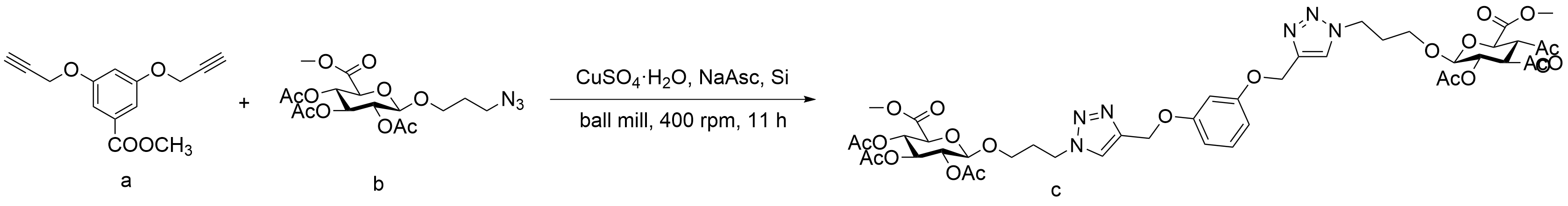

2.1 球磨-CuAAc反应

表2 球磨-CuAAc反应与溶液-CuAAc产率对比Table 2 Yields from Ball-milled CuAAc versus CuAAc in solution reaction |

| Product | Catalyst | Yields from solution reaction[%]a | Yields from ball mill[%]b |

|---|---|---|---|

| Cu(OAc)2 | 21 | 57 |

| CuI | 5 | 85 | |

| Cu(OAc)2 | 45 | 60 |

| CuI | 40 | 87 | |

| Cu(OAc)2 | 89 | 77 |

| CuI | 52 | 92 | |

| Cu(OAc)2 | 10 | 72 |

| CuI | 5 | 79 |

aSolution reaction condition:3.5 h,60℃. Methanol solvent was used for Cu(OAc)2;CuI, N,N-Diisopropylethylamine was used as the additive, CH2Cl2 was used as the solvent; bBall mill reaction condition:3.5 h,room temperature,two 7 mm stainless steel balls, PTFE milling jar, 30 Hz. Cu(OAc)2 was used without additives or solvents; CuI was used with N,N-Diisopropylethylamine and acetic acid |

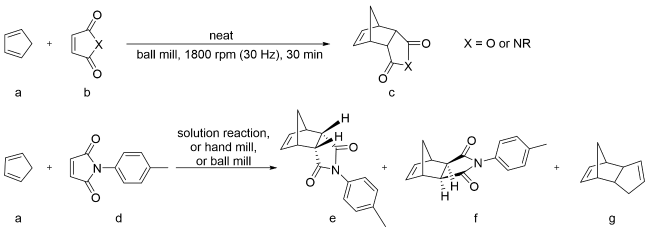

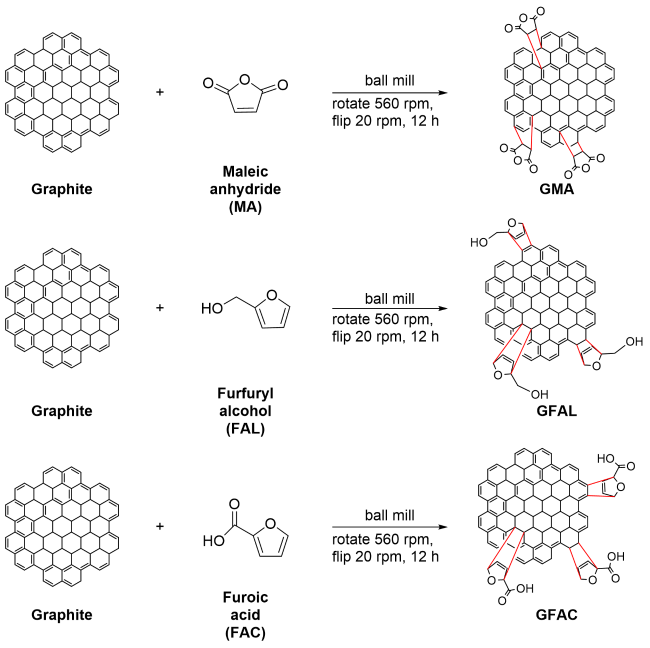

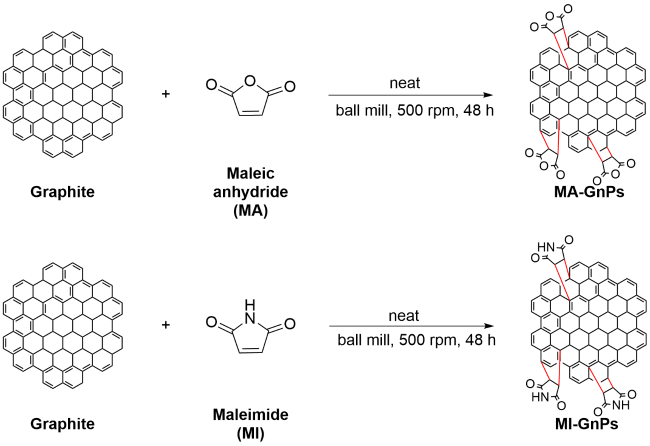

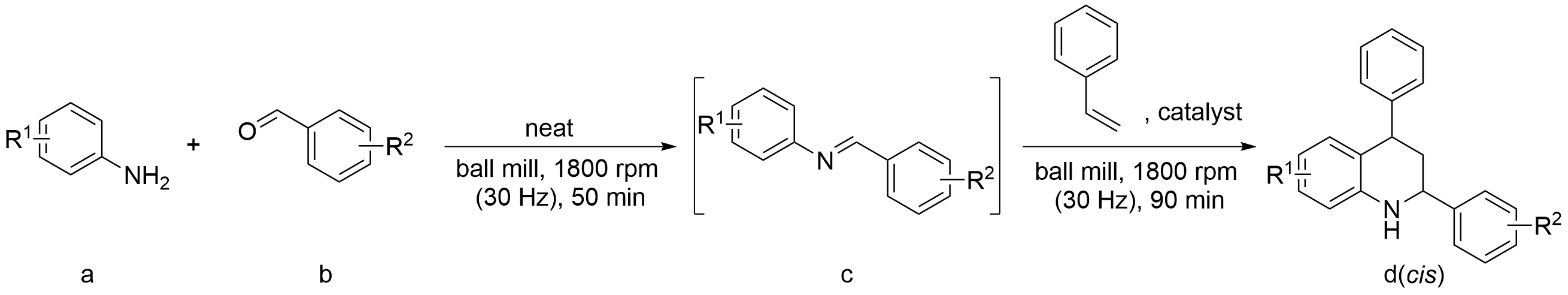

2.2 球磨-Diels-Alder反应

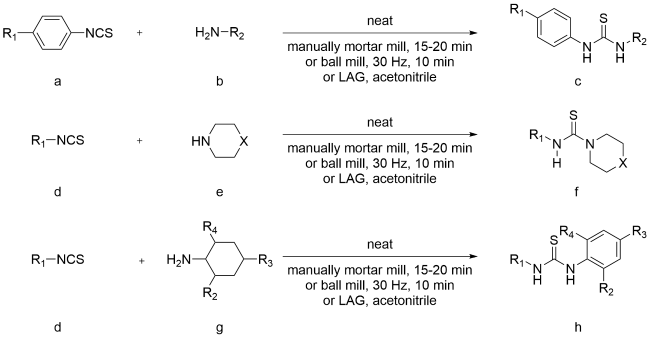

2.3 球磨-胺-异硫氰酸酯反应

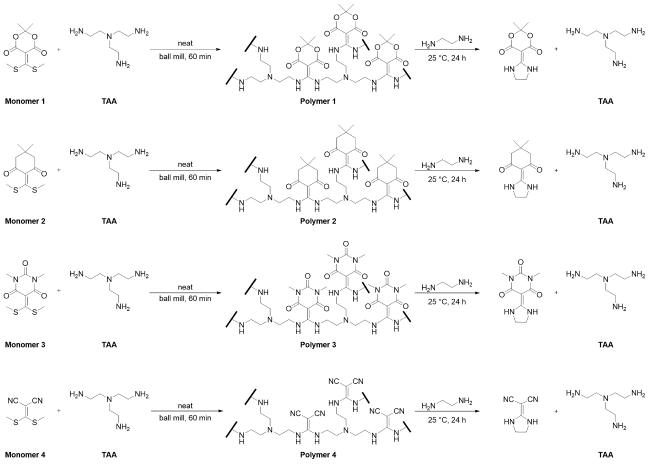

2.4 球磨-胺-硫醇反应

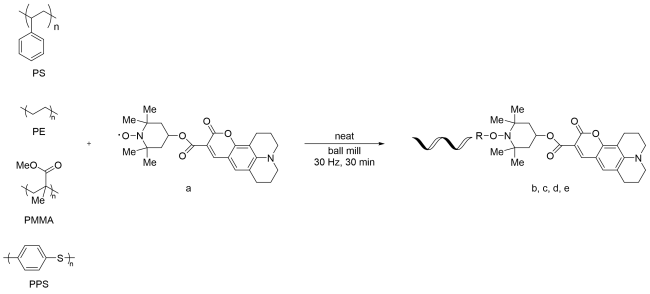

2.5 球磨-氧氮自由基偶联反应

3 反应条件对球磨-点击化学的影响

3.1 催化剂的种类与量对球磨-点击化学的影响

表3 醋酸铜、碘化铜、黄铜球的催化下,球磨CuAAc的反应产率Table 3 Ball-milled CuAAc yields catalyzed by Cu(OAc)2, CuI, or brass ball |

| Product | Catalyst | Yields[%] |

|---|---|---|

| Cu(OAc)2a | 57 |

| CuIb | 85 | |

| Brass ballc | 77 | |

| Cu(OAc)2a | 60 |

| CuIb | 87 | |

| Brass ballc | 80 | |

| Cu(OAc)2a | 77 |

| CuIb | 92 | |

| Brass ballc | 87 | |

| Cu(OAc)2a | 72 |

| CuIb | 79 | |

| Brass ballc | 76 |

aReaction condition:Cu(OAc)2, two 7 mm stainless steel balls, PTFE milling jar, 30 Hz, 3.5 h, room temperature; breaction condition: CuI, N,N-Diisopropylethylamine, acetic acid, two 7 mm stainless steel balls, PTFE milling jar, 30 Hz, 3.5 h,room temperature; creaction condition: N,N-Diisopropylethylamine, acetic acid, two 7 mm brass balls, PTFE milling jar, 30 Hz, 3.5 h, room temperature |

表4 一锅法球磨CuAAc在不定量的催化剂下的产率Table 4 One pot ball-milled CuAAc yields under varied catalyst dose |

| ||

|---|---|---|

| Number | Catalyst amount (mol%) | Yields(%) |

| 1 | 0 | 0 |

| 2 | 2 | 51 |

| 3 | 5 | 72 |

| 4 | 10 | 96 |

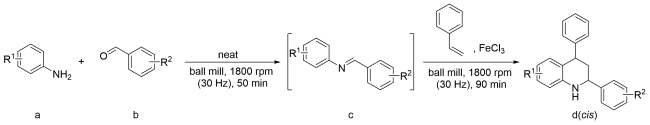

表5 球磨Diels-Alder反应中Lewis酸和Bronsted酸催化剂对产率的影响Table 5 Ball-milled Diels-Alder reaction yields catalyzed by Lewis acids or Bronsted acids |

| ||

|---|---|---|

| Number | Catalyst | Yields(%) |

| 1 | ZnCl2 | 76 |

| 2 | AlCl3 | 85 |

| 3 | CuCl2 | 15 |

| 4 | FeCl3 | 86 |

| 5 | Cu(OAc)2 | 10 |

| 6 | Co(OAc)2 | Not detected |

| 7 | Mn(OAc)2 | Trace |

| 8 | Pd(OAc)2 | Trace |

| 9 | BF3·OEt2 | 81 |

| 10 | Cu(OTf)2 | 56 |

| 11 | TFA | 48 |

| 12 | p-TsOH | 12 |

| 13 | KHSO4 | Trace |

| 14 | KH2PO4 | Not detected |

3.2 研磨球的大小与数量对球磨-点击化学的影响

表6 相同总质量,不同大小和数量研磨球对反应的影响Table 6 Yields from different mill balls in terms of sizes and numbers |

| |||||

|---|---|---|---|---|---|

| Number | Ball numbers | Effective surface area a(mm2) | Yields (%) | ||

| 2mm Ø | 5mm Ø | 10mm Ø | |||

| 1 | 0 | 0 | 10 | 10666 | 67 |

| 2 | 625 | 0 | 10 | 18520 | 80 |

| 3 | 1500 | 48 | 0 | 30144 | 99 |

aEffective surface area=surface area of balls+surface area of the jar |

3.3 添加剂对球磨-点击化学的影响

表7 一锅法球磨CuAAC在不定量K2CO3添加剂下的产率Table 7 One pot ball-milled CuAAC yields with varied K2CO3 additives |

| ||

|---|---|---|

| Number | K2CO3(equivalent) | Yields(%) |

| 1 | 0 | 52 |

| 2 | 1 | 91 |

| 3 | 3 | 90 |

3.4 试剂的比例对球磨-点击化学的影响

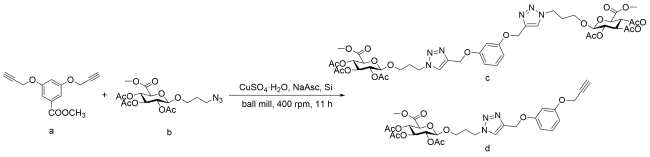

表8 球磨CuAAc中试剂比例对产率的影响Table 8 Ball-milled CuAAc yields impact by stoichiometric ratio |

| |||

|---|---|---|---|

| Number | Stoichiometry a:b:CuSO4·H2O:NaAsc | Reaction time | Conversion(%) |

| 1 | 0.5:1.1:0.2:0.35 | 9 | 54 |

| 2 | 0.5:1.65:0.3:0.53 | 9 | 61 |

| 3 | 0.5:2.5:0.3:0.53 | 11 | 65 |

| 4 | 0.5:3.5:0.4:0.7 | 11 | >99 |

3.5 反应时间对球磨-点击化学的影响

表9 一锅法球磨CuAAc在不同反应时间下的产率Table 9 One pot ball-milled CuAAc yields under varied reaction time |

| ||

|---|---|---|

| Number | Time (min) | Yields (%) |

| 1 | 30 | 62 |

| 2 | 45 | 80 |

| 3 | 60 | 96 |