1 引言

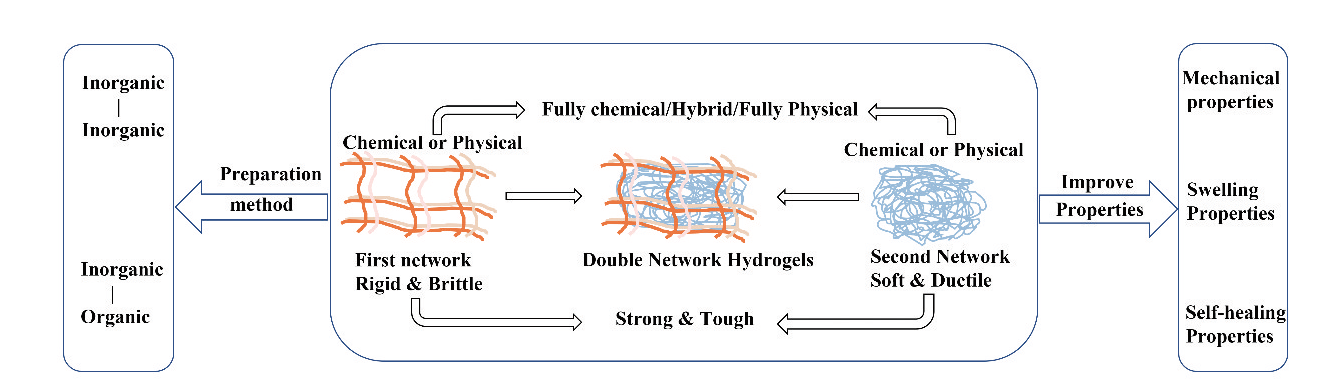

2 双网络水凝胶种类及其制备

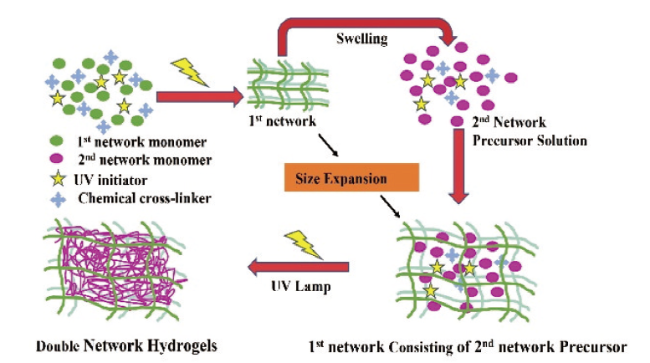

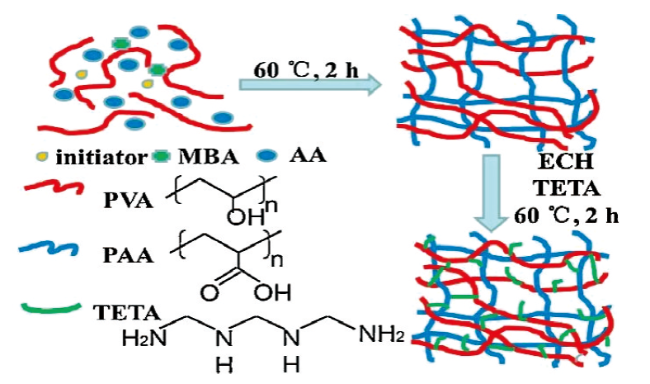

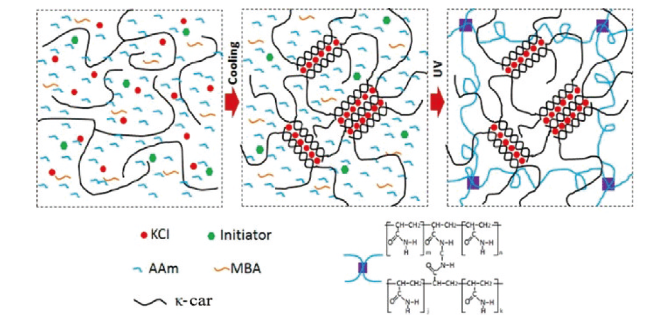

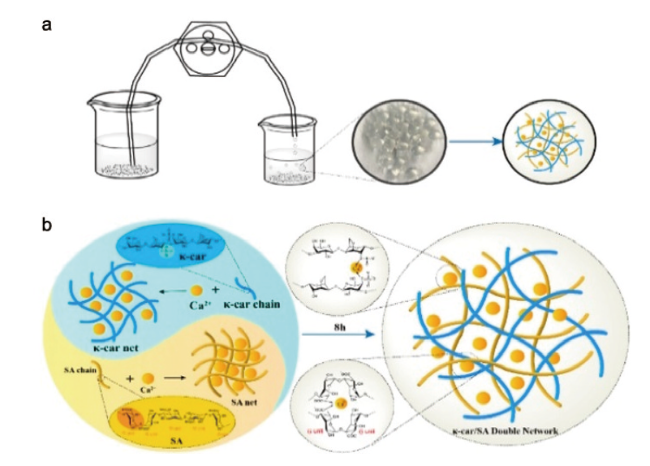

2.1 有机-有机类双网络水凝胶制备研究

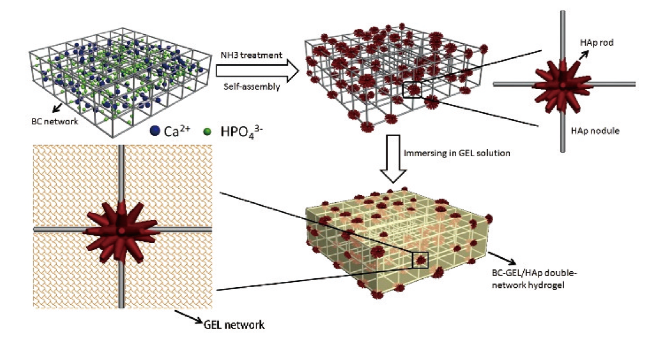

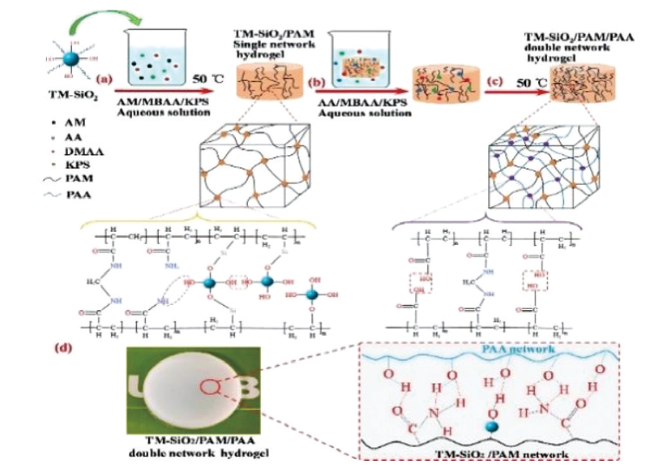

2.2 有机-无机类双网络水凝胶制备研究

表1 各种双网络水凝胶的制备方法和性能Table 1 Preparation methods and properties of various double network hydrogels |

| Category | Double Network hydrogels | Preparation method | Performance | ref |

|---|---|---|---|---|

| Organic-organic double network hydrogels | PVA/PAM-co-PAA | Two-steps methods of copolymerization and freezing/thawing | High strength and toughness(1230±90 kPa和1250±50 kJ / m3), fast self-recovery | 19 |

| PVA/PAA | Two-step method | After 5 adsorption-desorption cycles, the removal rate remained nearly 100% | 20 | |

| κ-car/SA | Calcium-hardening method | The maximum adsorption capacity for CIP reaches 220 mg/g | 24 | |

| κ-car/PNAGA | One-pot method | The hydrogel, cut in half, was annealed at 90℃ for 3 hours and subsequently healed and withstood bending and stretching by hand | 25 | |

| Organic-inorganic double network hydrogels | GO/PAA | Two step synthesis | After the press is compressed, the press is removed and the press can also be restored to its original shape | 30 |

| Alginate/RGO | Hydrothermal reduction method | After 10 cycles, the adsorption capacities of Cr2 and Cu2+on the GAD were maintained at 48.23 and 92.12 mg·g-1, respectively | 28 | |

| GO/SA | Soaking method | After 18 adsorption-desorption cycles, the adsorption capacity of GAD hydrogel for Mn (II) remained unchanged at 11.2 mg/g | 31 | |

| PAM/SAC | Solution polymerization method | Tensile properties (stress and strain are 12 MPa and 2500%, respectively) and compressive strength (stress and strain are 65 MPa and 80%, respectively) | 32 | |

| Silica particles/PDMAAm | One-pot method | The DN ion gels with an 80 wt% IL content show more than 28 MPa of compressive fracture stress | 33 | |

| BC-GEL / HAp | Soaking method | Has a higher modulus of elasticity (0.27 MPa) and fracture (0.28 MPa) | 34 |

3 提升双网络水凝胶性能方面的研究

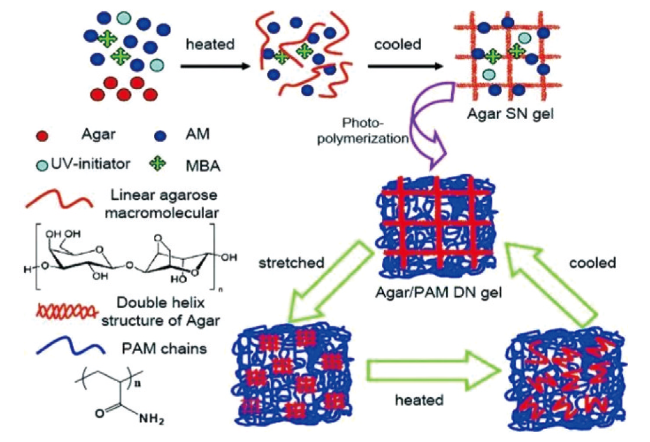

3.1 提升机械性能

3.2 提升抗溶胀性能

3.3 提升自修复性能

表2 各种双网络水凝胶的力学性能Table 2 Mechanical properties of various double network hydrogels |

| Improve mechanical properties | Double Network hydrogels | Performance | ref |

|---|---|---|---|

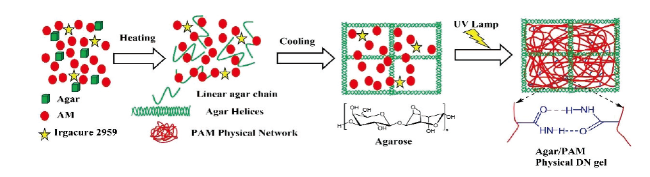

| Improved mechanical properties | agar/PAM | Able to withstand high levels of compression and stretching | 41 |

| curdlan/PAM | Tensile rupture strength of 0.81 MPa, tensile stress of 25.3 MPa | 42 | |

| TM-SiO2/ PAM/PAA | Both tensile and compressive strength have increased, and the network structure is more stable | 43 | |

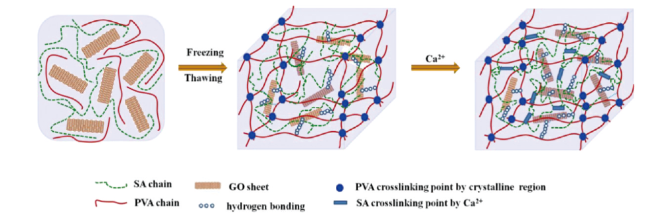

| GO/SA/PVA | The breaking strength increased from 0.11 MPa of pure SA/PVA to 0.24 MPa | 44 | |

| Improved anti-swelling performance | PVA/P(AM-co-AA)/CS | Strong electrostatic interactions reduce the swelling rate of hydrogels | 53 |

| SA/CS/Zn2+ | The swelling rate of the hydrogel decreases with increasing zinc content | 54 | |

| GO/ CA/PAM | Smaller dissolution changes in visual model plots | 55 | |

| PAA/P (AM-co-AA sodium salts) | Remarkable swelling characteristics (an SR of 1200% ± 20% and an unusually high compressive modulus of 10.12 ± 0.31 MPa) | 56 | |

| SSH | Compression modulus increases by 15.6% ± 4.5% at a 25% swelling rate | 57 | |

| BCD-AMPS/PAM | Reactive strand extensions of up to 40% lead to hydrogels that stretch 40% to 50% further and exhibit tear energies that are twice as large. | 58 | |

| Improve self-healing performance | Alginate/ polyacrylamide | After standing at 80℃ for 1 day, the recovery relative to the initial value was 74% | 62 |

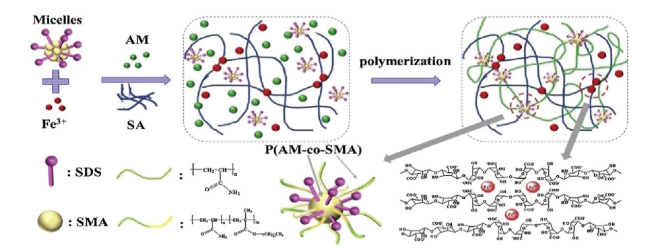

| PAM/SA-Fe | The breaking strength and toughness recovered 103.85% and 75.54%, respectively, within 1 min | 63 | |

| Agar / PAM | After standing for 2 min at room temperature without external stimuli, toughness recovers approximately 83% | 64 | |

| ST/ PAA/ AMPS | The damage at the cutting interface will slowly but steadily self-repair to its initial state | 65 |