PDF(4291 KB)

PDF(4291 KB)

PDF(4291 KB)

PDF(4291 KB)

PDF(4291 KB)

PDF(4291 KB)

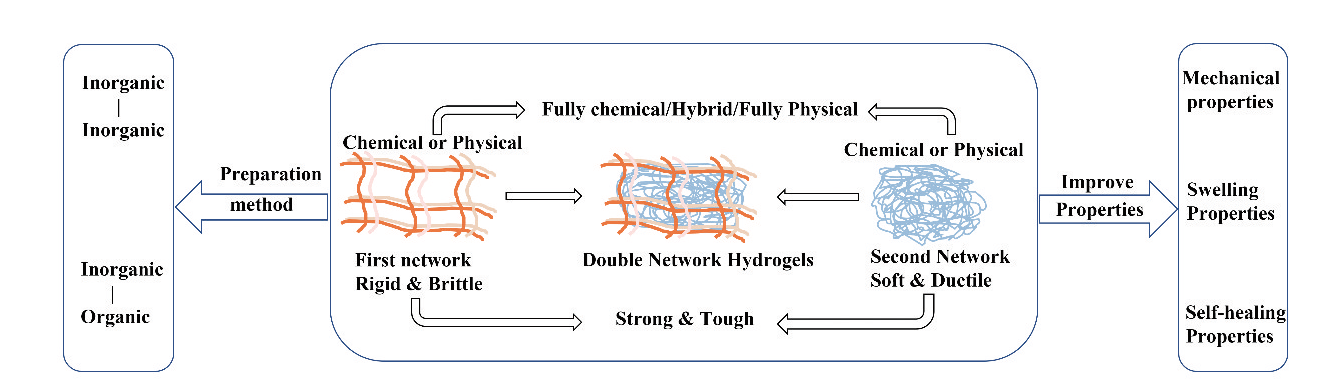

双网络水凝胶制备及其力学改性

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of Double Network Hydrogels and their Mechanical Modification

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |