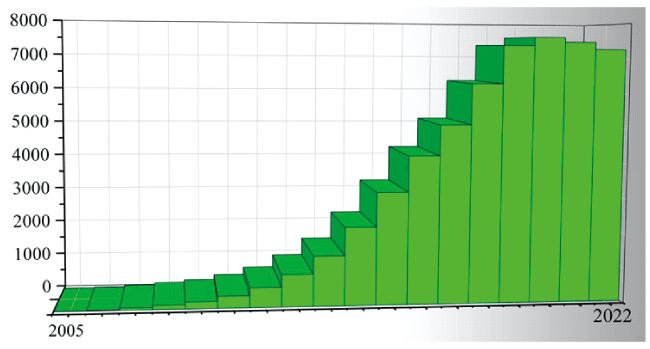

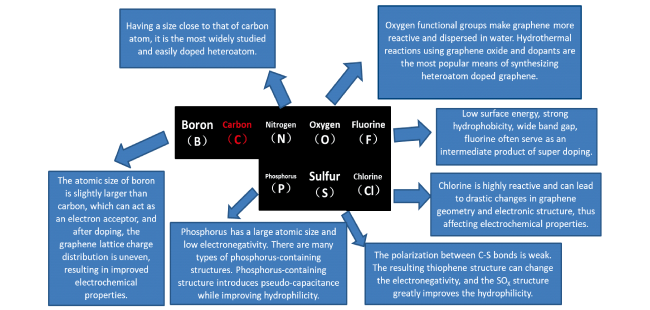

1 引言

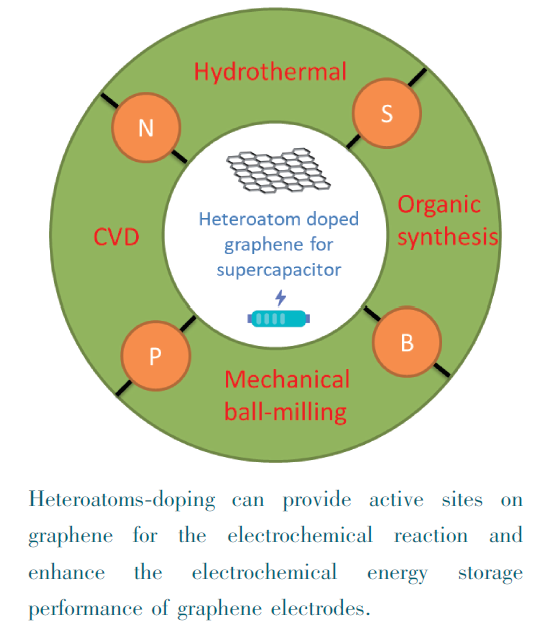

2 杂原子掺杂石墨烯的制备

2.1 化学气相沉积法(CVD)

2.2 化学合成法

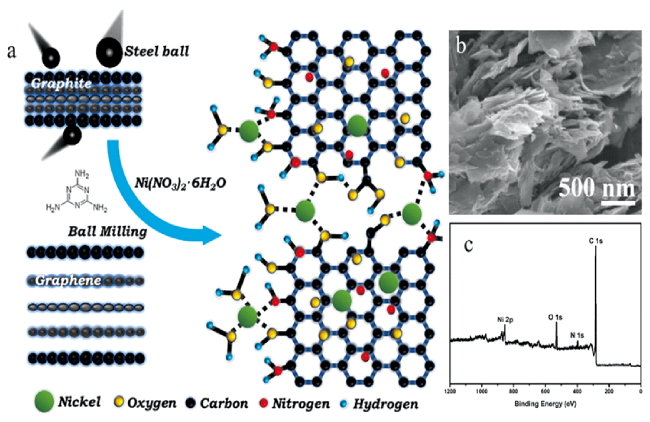

2.3 机械球磨法

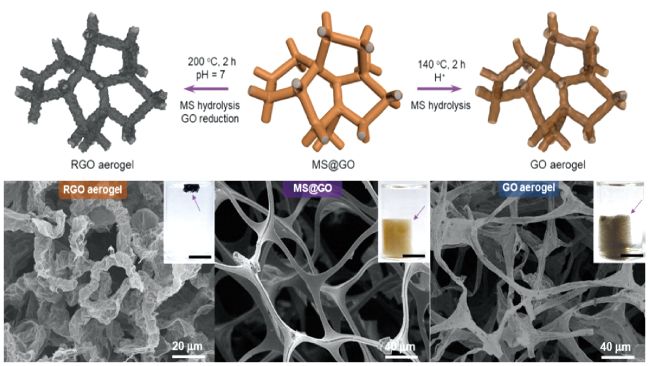

2.4 水热法

2.5 其他合成方法

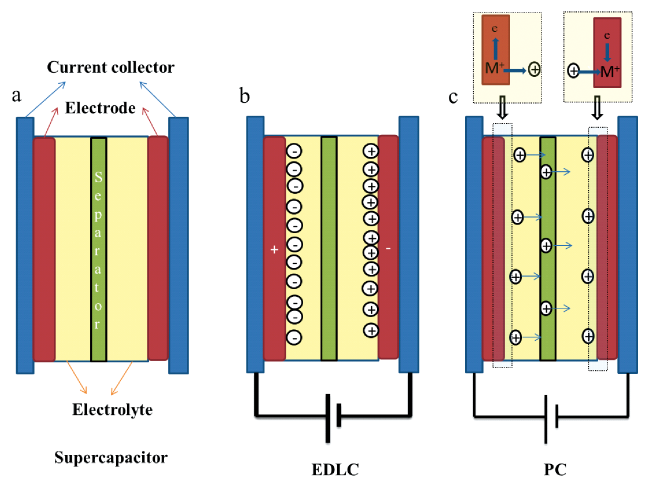

3 杂原子掺杂石墨烯应用于超级电容器电极材料

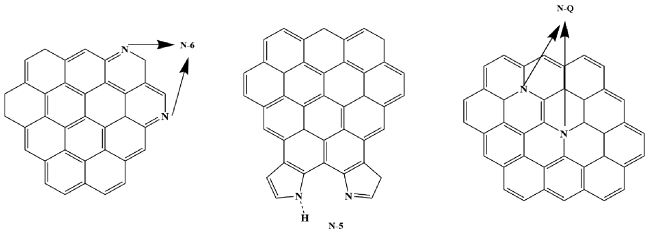

3.1 氮掺杂

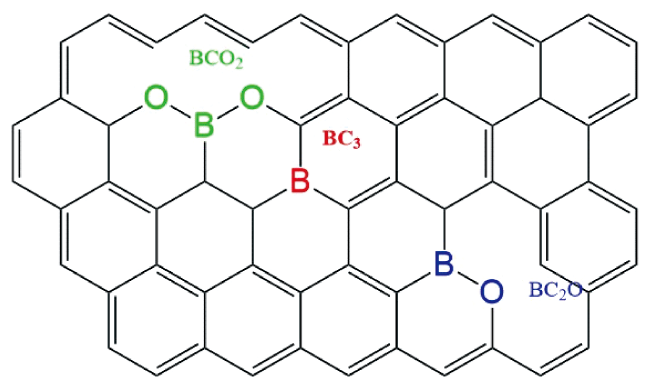

3.2 硼掺杂

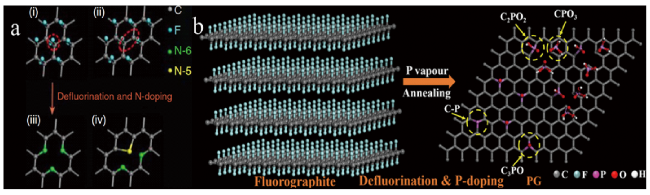

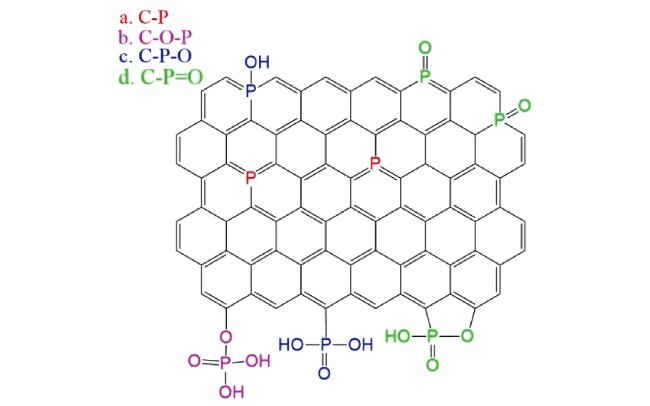

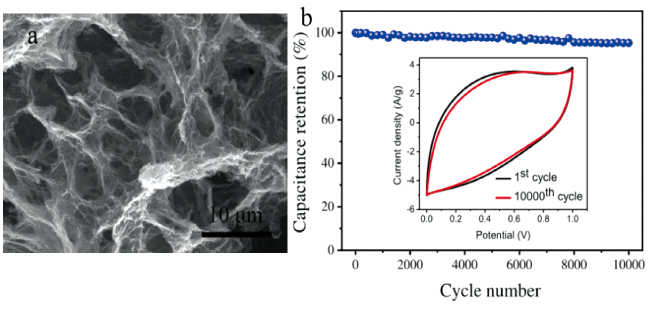

3.3 磷掺杂

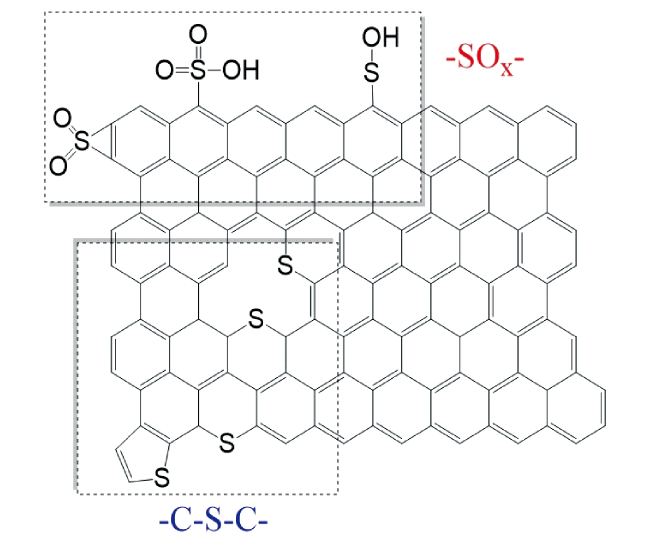

3.4 硫掺杂

3.5 其他杂原子掺杂

3.6 多种原子共掺杂

表1 杂原子掺杂石墨烯作为超级电容器电极材料的性能比较Table 1 Performance of heteroatom-doped graphene as electrode materials for supercapacitors |

| Material | Atom(s) | Synthesis method/ React condition | Dopant | Carbon source | Performance | Ref | |

|---|---|---|---|---|---|---|---|

| 1 | N-HtrGO | N | Hydrothermal/150℃, 12 h | Urea | GO | 244 F/g at 50 mV/s, 105% at 2000 cycles | 86 |

| 2 | NHGNSs | N | Thermally annealed/ 360℃, 5 h | NH3 | GO | 126 F/g at 1 A/g, 91% at 2000 cycles | 66 |

| 3 | PG-Ni | N | Thermally annealed/ 800℃, 2 h | N2 | GO | 575 F/g at 0.5 A/g, 89.5% at 10 000 cycles | 68 |

| 4 | FNG | N | Ball milling/500 rpm, 24 h | Melamine | Expanded graphite | 83.8 mF/cm2 at 0.6 mA/cm2, 93.8% at 5000 cycles | 38 |

| 5 | NG-DWCNT | N | CVD/ 1300℃ under Ar | Urea | Ethanol | 563 F/g at 50 A/g, 94.35% at 5000 cycles | 27 |

| 6 | NGH | N | Hydrothermal/ 90℃, 4 h | Carbamide | GO | 199.8 F/g at 2 A/g, 97% at 20000 cycles | 87 |

| 7 | NG | N | Hydrogel strategy | Pyrrole | GO | 455.4 F/g at 1 A/g, 97.4% at 5000 cycles | 88 |

| 8 | BMG | B | Hydrothermal/180℃, 4 h | Boric acid | GO | 336 F/g at 0.1 A/g, 98% at 5000 cycles | 89 |

| 9 | HTBAGO | B | Supercritical fluid processing/400℃, 1 h | Boric acid | GO | 286 F/g at 1 A/g, 96% at 10 000 cycles | 70 |

| 10 | B-rGO | B | Electrochemical synthesis | Boric acid | GO | 446 F/g at 0.1 A/g, 95.6% at 2000 cycles | 90 |

| 11 | BGNS | B | Solvothermal/150℃, 12 h | Boric acid | GO | 125 F/g at 1 A/g, 83% at 2000 cycles | 91 |

| 12 | P-TRG | P | Thermal annealing/ 800℃, 30 min | H3PO4 | GO | 115 F/g at 0.05 A/g, 97% at 5000 cycles | 72 |

| 13 | PO-graphene | P | Electrochemical synthesis | (NH4)3PO4 | Graphite rod | 1634.2 F/g at 3.5 mA/cm2, 67% at 500 cycles | 92 |

| 14 | PGA | P | Solvothermal/150℃, overnight | Phytic Acid | GO | 225.3 F/g at 1 A/g, 95% at 10 000 cycles | 73 |

| 15 | PGO | P | Supercritical fluid processing/400℃, 1 h | Na3PO4 | GO | 518 F/g at 1 A/g, 98% at 5000 cycles | 93 |

| 16 | S-GEs | S | Electrochemical synthesis | H2SO4 | Pencil graphite | 1833 mF/cm2 at 10 mA/cm2, 95% at 1000 cycles | 74 |

| 17 | S@G | S | Heat treatment/155℃, 8 h | S | Nanomesh graphene | 257 F/g at 0.25 A/g, 87% at 10 000 cycles | 94 |

| 18 | S-rGO | S | Microwave-assisted synthesis/140℃, 30 min | Na2S | GO | 237.6 F/g at 0.1 A/g, 113% at 5000 cycles | 75 |

| 19 | L-P LIG | S | Laser direct writing | Polyethersulfone | Lignin | 22 mF/cm2 at 0.05 mA/cm2, 89.8% at 9000 cycles | 95 |

| 20 | Cl-RGOFs | Cl | Hydrothermal/180℃, 3 h | HCl | GO | 210 F/g at 1 A/g, 94.3% at 5000 cycles | 77 |

| 21 | FGA | F | Hydrothermal/150℃, 12 h | HF | GO | 279.8 F/g at 0.5 A/g, 94.3% at 5000 cycles | 96 |

| 22 | NiNOG | Ni, N, O | Ball milling/ 400 rpm, 10 h | Ni(NO3)2·6H2O Melamine | Graphite | 532 F/g at 1 A/g, 87.5% at 10 000 cycles | 40 |

| 23 | NP-rGO | N, P | Supramolecular polymerization | Melamine Phytic acid | GO | 416 F/g at 1 A/g, 94.63% at 10 000 cycles | 97 |

| 24 | s-SPG | S, P | Thermal activation/ 900℃, 1 h | Phytic acid Thioglycolic acid | GO | 168 F/g at 1 A/g, 91.7% at 2000 cycles | 54 |

| 25 | N, S, PHHGO | N, S, P | Hydrothermal/ 140℃, 2 h | NH4H2PO4 L-cysteine | GO | 295 F/g at 1 A/g, 93.5% at 10 000 cycles | 85 |

| 26 | S, N-FLG | N, S | Microwave irradiation/900 W and 2.45 GHz for a few seconds | H2SO4 HNO3 | Graphite | 298 F/g at 1 A/g, 95% at 10 000 cycles | 84 |