1 引言

2 零维多孔电磁波吸收材料

表1 常见零维多孔电磁波吸收材料的制备方法与性能Table 1 Preparation and properties of zero-dimensional porous absorbing materials |

| Materials | Synthesis method | Structure | Frequency (GHz) | Reflection loss (dB) | Thickness (mm) | Effective bandwidth (GHz) | ref |

|---|---|---|---|---|---|---|---|

| FeNi | Precipitation and thermal decomposition | Porous particle | 6.82 | -52.58 | 2 | 2.57 | 15 |

| Carbon/CoNi | Pyrolysis | Porous polyhedrons | 10.8 | -52 | 3 | 6.2 | 16 |

| Bi0.9La0.1FeO3 | Molten salt method and acid corrosion method | Flower-like | 6.9 | -57.9 | 2.9 | 2.7 | 40 |

| C@PANI | Roasting and coating process | 3D porous structure | 12.6 | -72.16 | 2.6 | 6.64 | 41 |

| Ni/C | Solvothermal method and carbon reduction | Porous microspheres | 2.6 | -44.5 | 9.5 | 8.2 | 42 |

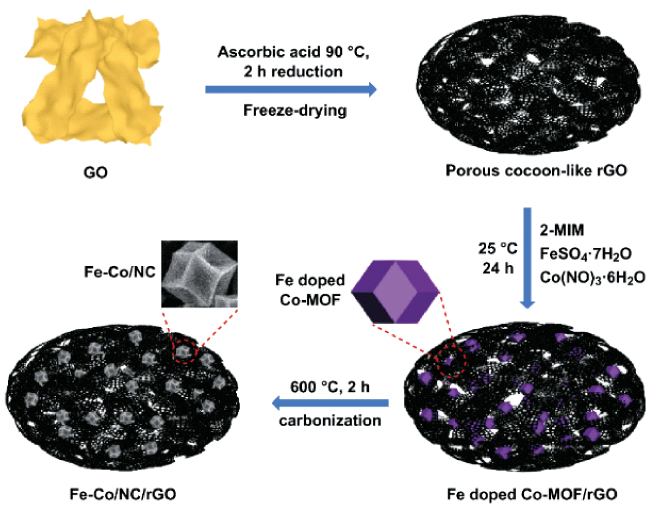

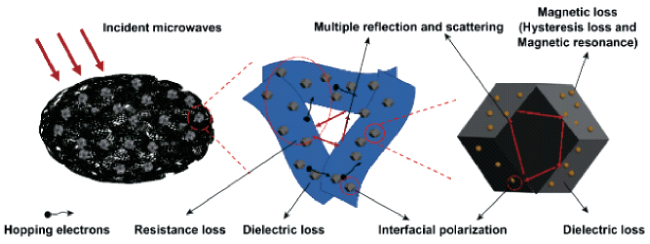

| FeCo/NC/rGO | Freeze drying | Hierarchically porous structure | 11.28 | -43.26 | 2.5 | 9.12 | 43 |

| Fe3O4@C | Situ polymerization and carbonization | Core-shell | 4.8 | -36 | 5 | 3.7 | 44 |

| rGO | Freeze-drying | Cocoon-like | 15.96 | -29.05 | 2 | 5.27 | 45 |

| rGO/MXene/Fe3O4 | Ultrasonic spray technology | Pleated porous microsphere | 11.1 | -51.2 | 2.9 | 6.5 | 46 |

| MnO/Co/C | Hydrothermal and carbonization | Porous microspheres | 11.92 | -68.89 | 2.6 | 5.3 | 47 |

| CNT/pyrolytic carbon | In-situ growth | Hollow microspheres | 12.2 | -56 | 2.3 | 4 | 48 |

| N-Co/C | Solvothermal and carbonization | Porous bowl-like | 13.3 | -42.3 | 1.9 | 5.1 | 49 |

| C/S | Hydrogen peroxide etching and high temperature vulcanization | Hollow porous microspheres | 11.2 | -27.2 | 2.45 | 6.72 | 50 |

2.1 磁损耗型零维PEMAM

2.2 介电损耗型零维PEMAM

2.3 磁电复合型零维PEMAM

3 三维多孔电磁波吸收材料

表2 常见三维多孔电磁波吸收材料的制备方法与性能Table 2 Preparation and properties of three-dimensional porous absorbing materials |

| Materials | Synthesis method | Structure | Frequency (GHz) | Reflection loss (dB) | Thickness (mm) | Effective bandwidth (GHz) | ref |

|---|---|---|---|---|---|---|---|

| NiO/NiFe2O4/Ni | Leaven dough route | Foam | 16.9 | -50 | 2.1 | 14.24 | 35 |

| Graphene | Freeze drying and solvothermal | Foam | 34.4 | -33.2 | 1 | 60.5 | 38 |

| rGO/α-Fe2O3 | Hydrothermal method | Foam | 7.12 | -33.5 | 5 | 6.4 | 64 |

| Fe3O4/C | Solvothermal approach and carbon reduction | Flower and porous sheet | 5.7 | -54.6 | 4.27 | 6 | 65 |

| MWCNT/graphene | Solvothermal | Foam | 11.6 | -39.5 | — | 12 | 66 |

| MWCNT/WPU | Freeze-drying | Foam | — | -50.5 | 2.3 | 4 | 67 |

| CNT/graphene | Chemical vapor deposition | Foam | — | -47.5 | 1.6 | 4 | 68 |

| Carbon | Hydrothermal and pyrolysis process | Foam | 15.8 | -52.6 | 2.6 | 8.6 | 69 |

| Graphene/carbon fibers | Dip-coating | Aerogel | 14.6 | -30.53 | 1.5 | 4.1 | 70 |

| Carbon/Ni | Alkaline activation process | Hierarchically porous | 4.3 | -47 | 1.75 | 13.5 | 71 |

| rGO/Ti3C2Tx | Self-assembly | Hollow core-shell/foam | 8.8 | -22 | 3.6 | 4 | 72 |

| Al2O3/SiC | 3D printing and chemical vapor infiltration | Oblique honeycomb | 9.8 | -63.65 | 3.5 | 4.2 | 73 |

| — | 3D printing | Gradient porous structure | 2.5 | -33 | 20 | 14.06 | 74 |

| CNT/Fe3O4 | Freeze drying and low-temperature annealing | Aerogel | 16.4 | -59.85 | 1.5 | 3 | 75 |

| rGO/ZnO | Freeze-drying and hydrothermal | Foam | 9.57 | -27.8 | 4.8 | 4.2 | 76 |

| Si—O—C | 3D printing | Superstructure | 11.25 | -56.11 | 2.7 | 3.76 | 77 |

| Carbon/MnO2 | Carbonization and etching | Hollow | 14.9 | -48.87 | 2.5 | 7.8 | 78 |

| Carbon/MoS2 | Carbonization and hydrothermal | Honeycomb-like | 16.2 | -75.94 | 1.68 | 4.2 | 79 |

| Carbon/ZnFe2O4 | Pyrolysis carbonization | Honeycomb | 14.1 | -54.1 | 1.8 | 5.8 | 80 |

| Carbon/CuS | Carbonization and hydrothermal method | Porous/Hollow | 8.1 | -61.5 | 2.84 | 7.8 | 81 |

| Carbon/Fe/Fe2O3 | Hydrothermal and thermal treatment | Foam | 17.28 | -54.7 | 1.4 | 6.4 | 82 |

| Carbon | Hydrothermal | Nanosheets/Foam | 13.5 | -56.5 | 2.3 | 6.4 | 83 |

| Carbon/Co | Hydrothermal and pyrolysis | Mesoporous /Macroporous | 15.9 | -66.9 | — | 5.6 | 84 |

| rGO-Mo-WO3 | Solvothermal | Aerogel | 16.6 | -61.8 | 1.54 | 3.6 | 85 |

| Carbon/CoFe2O4 | Lyophilization/Pyrolysis | Aerogel | 15.58 | -52.29 | 2 | 5.36 | 86 |

| Co3O4/N-Carbon | Dipping growth | Foam | 10.72 | -46.58 | 3.3 | 5.4 | 87 |

| SiC | 3D printing and carbothermal reduction | 3D crosslinked biomimetic porous | 9.8 | -49.01 | 2.8 | 5.1 | 88 |

| Carbon | Low-temperature pre-carbonization/chemical activation | Hierarchically porous | 9.68 | -57.75 | 3.5 | 7.6 | 89 |

| Carbon/MnS | Electrospinning and high-temperature processing | Porous fibers | 11.1 | -68.9 | 3.6 | 7.2 | 90 |

| Carbon | Electrostatic spinning and heat treatment | Cross-linked fibers | 15 | -44.44 | 1.17 | 5.44 | 91 |

| CoNi@C | Hydrothermal and carbonization | Cylindrical pore | 11.12 | -75.19 | 2.66 | 4.56 | 92 |