1 引言

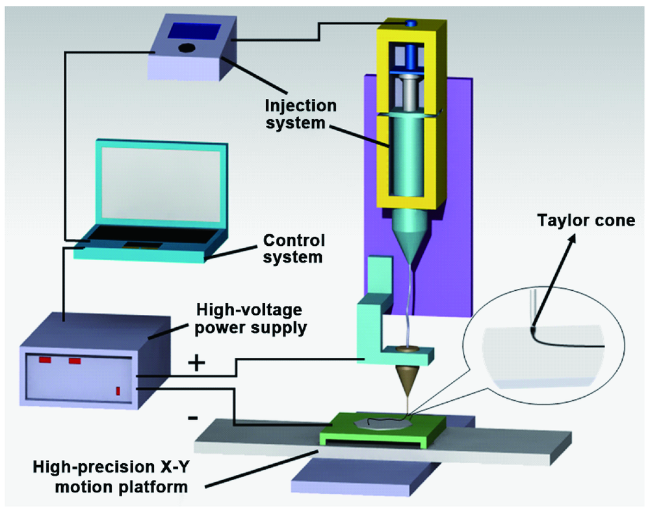

2 电流体动力喷墨打印

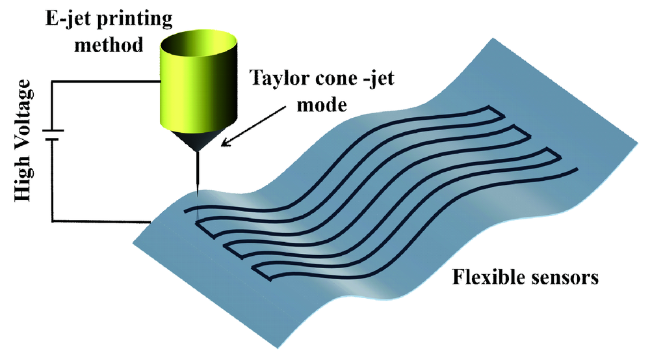

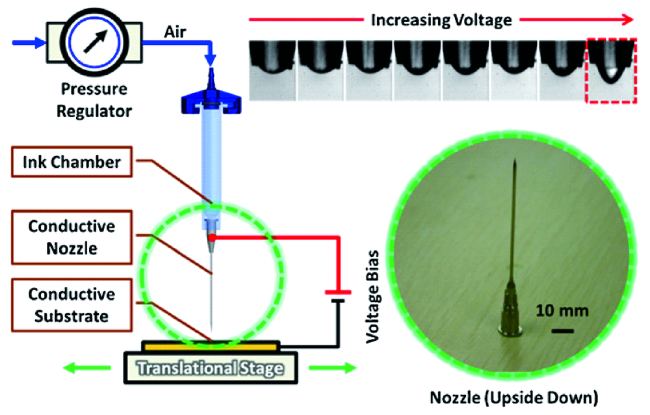

2.1 电流体动力喷墨打印技术

图4 (a)圆锥形喷射示意图[37]。由于在喷嘴尖端和基底之间施加电压产生电场,纳米颗粒墨水从喷嘴尖端形成锥形墨水弯液面的顶点墨水喷射;(b)喷嘴的SEM图像[37];(c)电喷印刷中观察到的6种不同模式[48]Fig. 4 (a) Schematic diagram of the Conical E-jet printing[37]. Due to the application of a voltage between the nozzle tip and the receiving substrate to generate an electric field, the nanoparticle ink is ejected from the apex of the conical ink meniscus formed at the tip of the nozzle nozzle. (b) SEM images of nozzle.[37]. Copyright 2007, Springer Nature. (c) Six different ejection modes observed in E-jet printing technique[48]. Copyright 2015, John Wiley and Sons |

2.2 电喷印刷中所用的功能墨水

2.2.1 金属材料

图5 (a)在柔性基底上电喷印刷银墨水的微电极阵列;(b)和(c)印刷的高分辨率图案[52];(d)曲面玻璃上电喷印刷金墨水的光学照片;(e)和(f)在12 V DC电压下加热器的红外图像[53]Fig. 5 (a) E-jet printed silver ink mic-roelectrode array on a flexible substrate. (b) and (c) Printed high resolution patterns[52]. Copyright 2013, Elsevier. (d) Optical photo of E-jet printing Au ink on curved glass. (e) and (f) Infrared image of heater at 12 V DC voltage[53] |

2.2.2 聚合物材料

2.2.3 碳导电材料和金属氧化物材料

图8 (a)电喷印刷通过静电纺丝和破碎工艺制备的金属氧化物纳米纤维;(b)在传感电极和加热器上电喷印刷制备纳米纤维气体传感器阵列[72]Fig. 8 (a) E-jet printing metal oxide nanofibers prepared by electrostatic spinning and crushing process. (b) Gas sensor array of nanofibers fabricated by E-jet printing on the sensing electrodes and microheaters[72]. Copyright 2017, Elsevier |

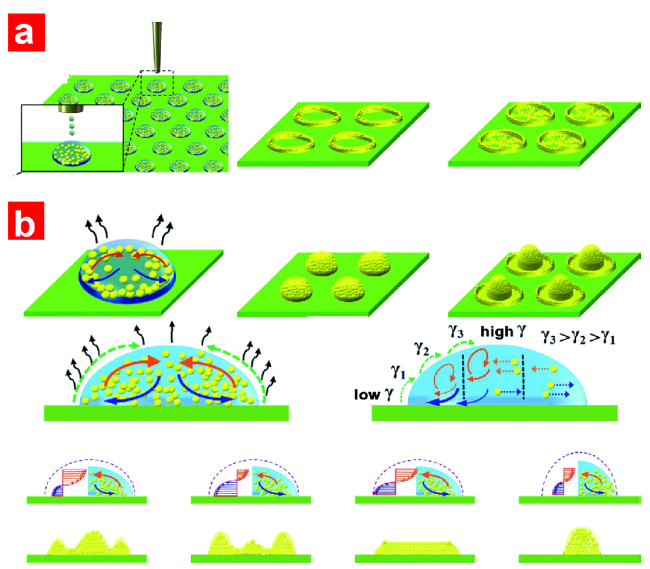

2.3 电喷印中的表界面调控

3 电喷印刷柔性传感器的应用

3.1 电喷印刷压力传感器

图13 (a)PDMS基底上电喷印刷圣诞树图案导体,(b)导体在弯曲状态下保持导电,(c)不同程度拉伸应变的光学照片,(d)和(e)导体过度拉伸导出现电路断开的光学照片,(f)和(g)电路断开被修复的光学照片,(h)修复后导体的弯折测试,(i)在多次拉伸-断开-修复测试后的半圆图案,(j)和(k)修复前后失败位置的光学图像,(l)循环拉伸应变函数图像[55]Fig. 13 (a) Optical picture of the conductor of the E-jet printed Christmas tree pattern on the PDMS substrate.(b) Conductivity test of the conductor in the bent state. (c) Optical photos of different degrees of tensile strain.(d) (a) and (b) An optical photo of a broken circuit caused by excessive stretching of theconductor.(c) and (d) an optical photo of the broken circuit being repaired.(e) bending test of the conductor after repair.(f) multiple stretch-break-Semicircle pattern after repair test.(g) and (h) Optical image of the failed position before and after repair.(i) Cyclic tensile strain function image, (j) and (k) optical images of failure positions before and after repair,(l) images of cyclic tensile strain function[55] |

3.2 电喷印刷气体传感器

图15 (a) 在不同电压下方波和三角波形状中的电喷印刷线条图案的光学显微镜图像;(b) 传感器在MEMS平台的应用;(c) 电喷印刷纳米纤维材料的扫描电子显微镜图像[72]Fig. 15 (a) Optical image of E-jet printed line patterns in wave and triangle wave shapes under different voltages. (b) The structure of biological field applications. (c) SEM image of E-jet printed nanofiber material[72]. Copyright 2017, Elsevier |

3.3 电化学传感器

图16 (a,b) 按需喷墨模式脉冲电压示意图;(c)按需喷墨印刷点阵列;(d)喷墨印刷连续线;(e)印刷石墨烯线电阻率和线宽随印刷次数的变化;(f)一次印刷石墨烯微结构的拉曼图像[69]Fig. 16 (a,b) Schematic diagram of pulse voltage in drop-on-demand inkjet mode. (c) Drop-on-demand E-jet printing dot array. (d) Inkjet printing continuous line. (e) Variations of resistivity and line thickness with the number of printing times. (f) Raman spectra of printed graphene[69] |