1 引言

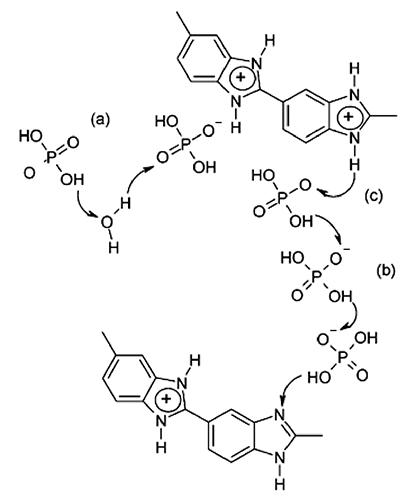

2 质子交换膜的质子传导机理

3 磷酸基高温质子交换膜面临的问题及挑战

4 磷酸基高温质子交换膜的改性

4.1 PBI 类高温质子交换膜

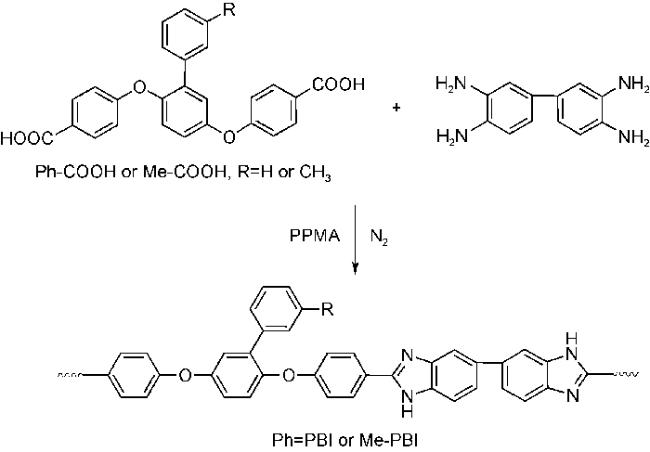

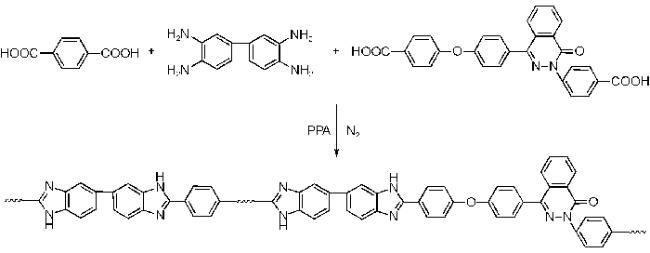

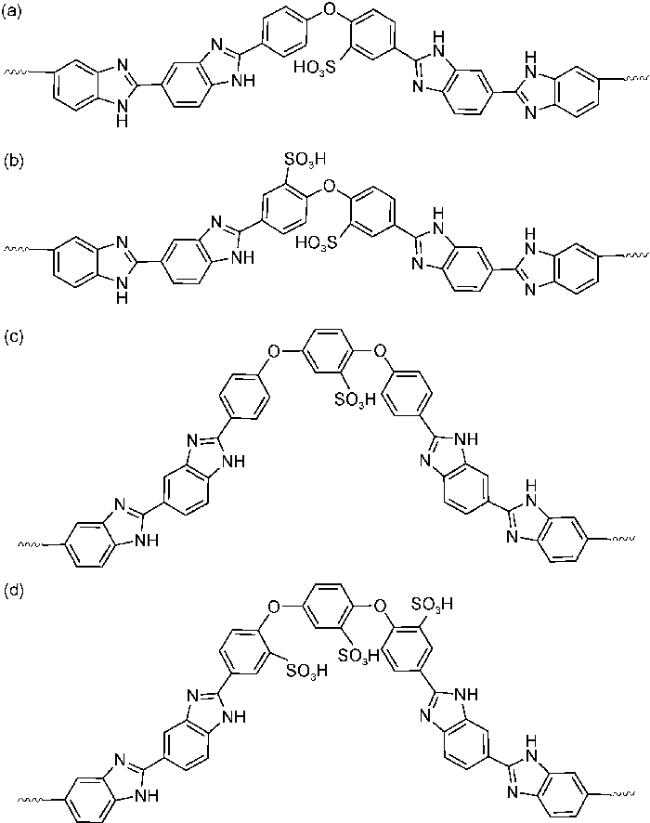

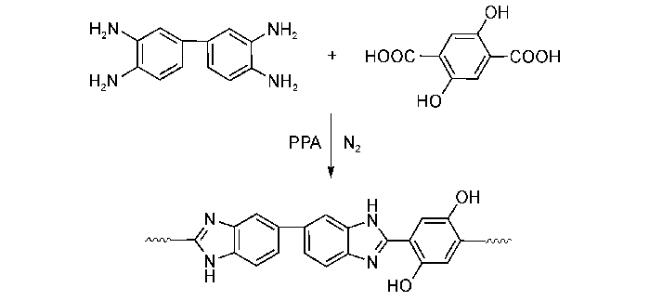

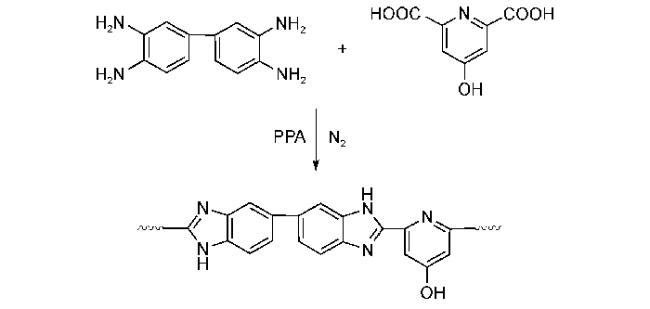

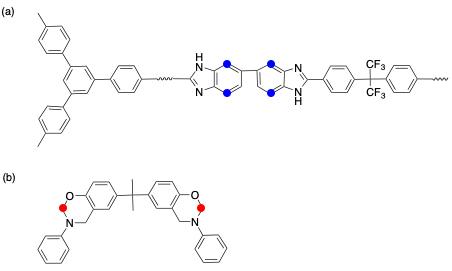

4.1.1 主链改性的聚苯并咪唑质子交换膜材料

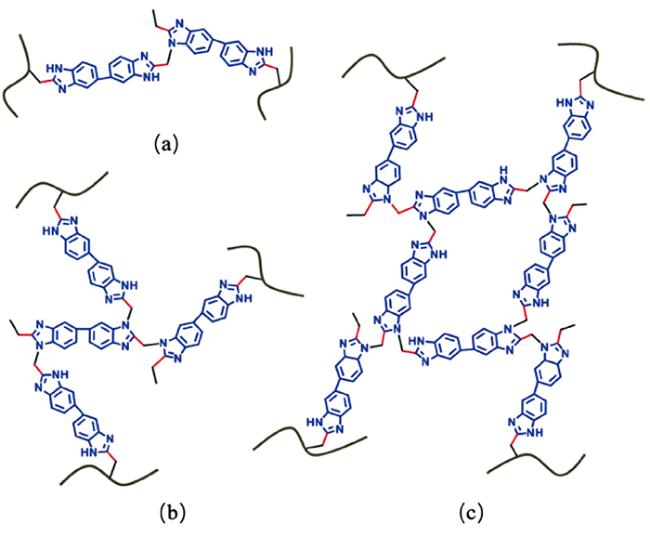

4.1.2 掺杂型聚苯并咪唑质子交换膜材料

4.1.3 交联或接枝型聚苯并咪唑质子交换膜材料

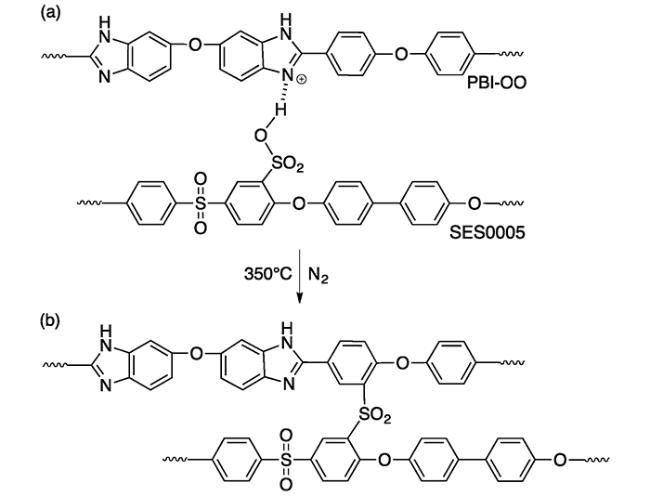

4.1.4 共混型聚苯并咪唑质子交换膜材料

)的存在,使得 PBI 非常容易吸水,阻止磷酸分子与 PBI 骨架的有效接触。Jana等[81]发现,PVDF 与 PBI 在一定比例内共混能提高磷酸掺杂水平,原因是 PVDF 作为疏水性高分子,可以抑制材料的吸水能力,从而负载更多酸。

)的存在,使得 PBI 非常容易吸水,阻止磷酸分子与 PBI 骨架的有效接触。Jana等[81]发现,PVDF 与 PBI 在一定比例内共混能提高磷酸掺杂水平,原因是 PVDF 作为疏水性高分子,可以抑制材料的吸水能力,从而负载更多酸。

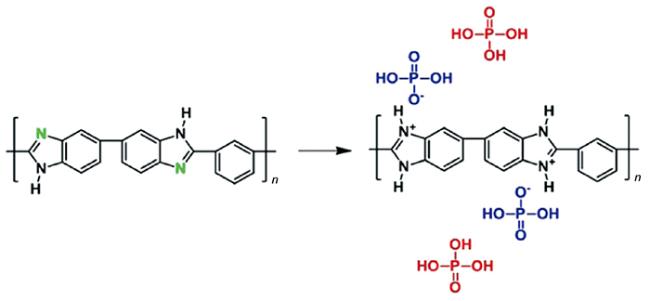

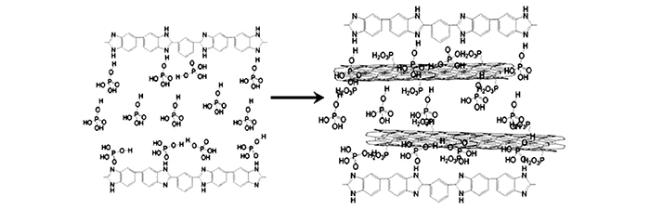

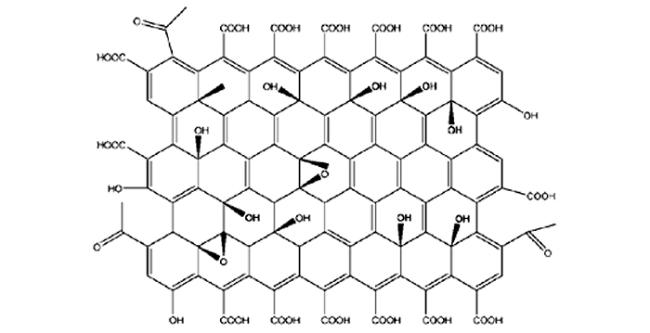

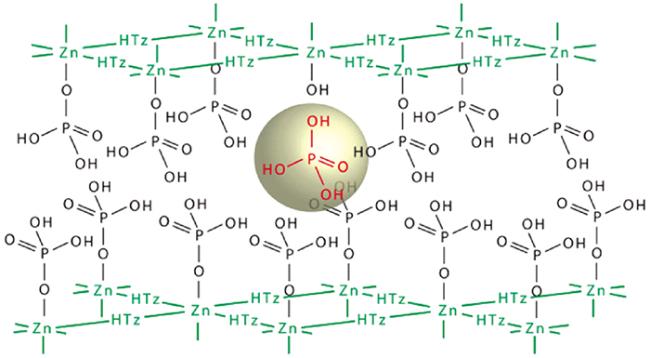

),可以与磷酸分子发生酸碱相互作用,从而产生“键合酸”,同时磷酸分子也可以通过氢键相互作用与聚合物骨架和其他磷酸分子连接,实际工作中磷酸掺杂量往往很高,这时分子链间存在大量的“游离酸”,与聚合物骨架共同形成氢键网络[

),可以与磷酸分子发生酸碱相互作用,从而产生“键合酸”,同时磷酸分子也可以通过氢键相互作用与聚合物骨架和其他磷酸分子连接,实际工作中磷酸掺杂量往往很高,这时分子链间存在大量的“游离酸”,与聚合物骨架共同形成氢键网络[