1 引言

2 基于柔性导电高分子复合材料应变传感器的分类

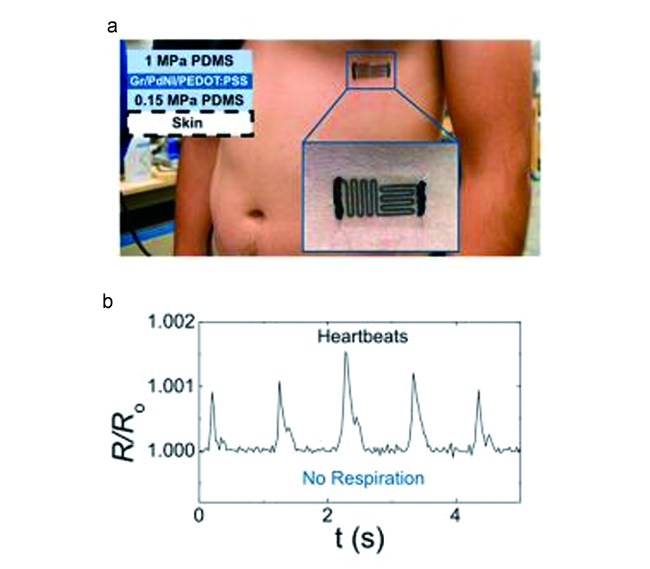

2.1 填充型应变传感器

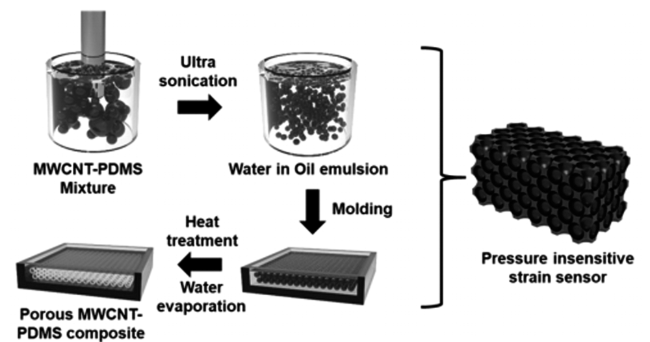

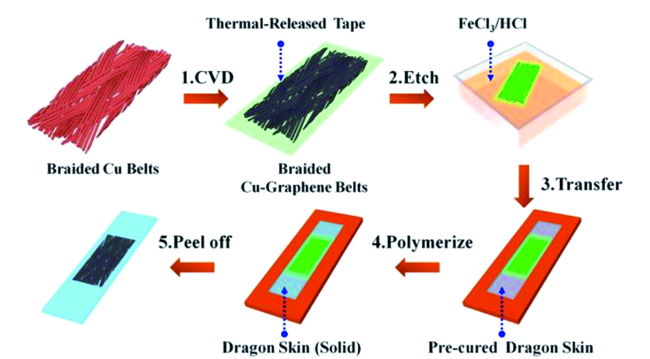

2.2 三明治型应变传感器

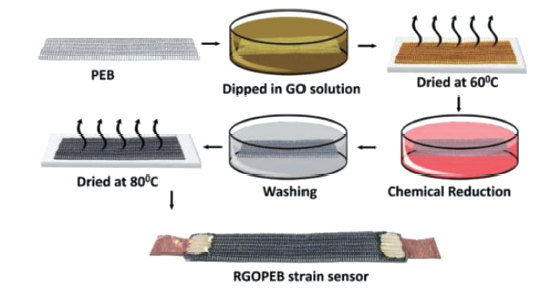

2.3 吸附型应变传感器

3 用于应变传感器的柔性导电高分子复合材料的内部结构

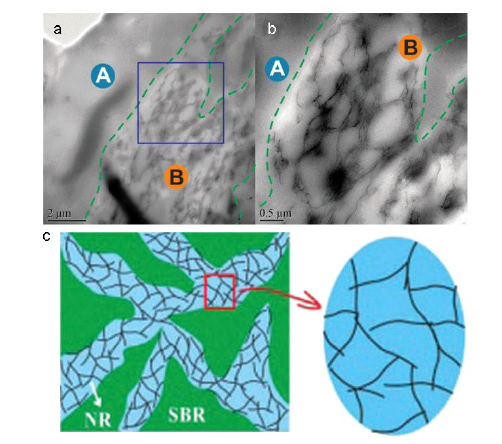

3.1 双逾渗网络结构

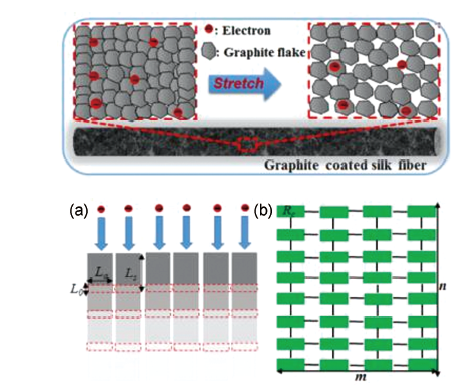

3.2 隔离结构

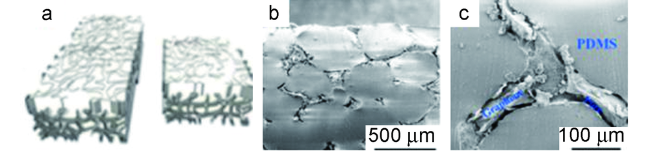

3.3 多孔结构

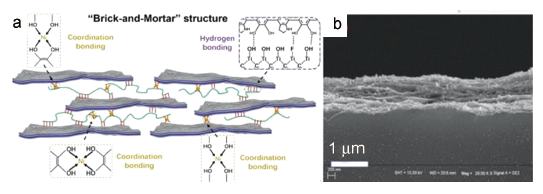

3.4 “砖混”结构

表1 不同复合材料的内部结构及其优缺点Table 1 The internal structure of different composites and their advantages and disadvantages |

| Internal structure | Advantage | Disadvantage | ref |

|---|---|---|---|

| Double percolation structure | Low percolation threshold | Conditions are difficult to control | 53 |

| Segregation structure | Lower percolation threshold | High technical requirements | 58 |

| Porous structure | High sensitivity | The preparation process is complex | 50 |

| “Brick-and-mortar” structure | Good mechanical properties | High percolation threshold | 76 |

4 用于应变传感器的柔性导电高分子复合材料的表面结构

表2 不同复合材料的表面结构及其优缺点Table 2 The surface structure of different composites and their advantages and disadvantages |

| Surface structure | Advantage | Disadvantage | ref |

|---|---|---|---|

| Wrinkles structure | High stretchability | Low sensitivity | 85 |

| Microcrack structure | High sensitivity | Worse stability | 92 |

4.1 褶皱结构

图8 (a)PEA基底上沉积rGO的褶皱结构的SEM图像和示意图;(b)HWETC在不同应变下的褶皱结构变化[85]Fig.8 (a) SEM images and illustrations of typical hierarchical wrinkles in the rGO layer deposited on the released PEA substrate; (b) Wrinkles structure changes under different strain of HWETC and SEM images are shown of short- and long-period wrinkles under the different HWETC strains[85]. Copyright 2016, Wiley-Blackwell |

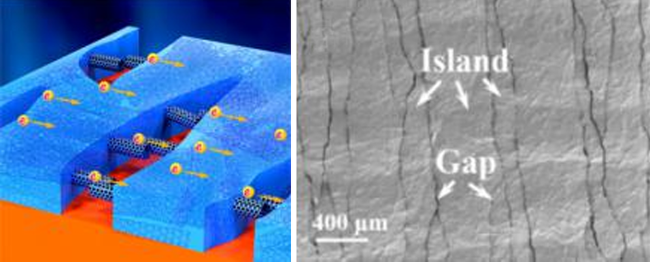

4.2 微裂纹结构

5 用于应变传感器的柔性导电高分子复合材料的宏观结构

表3 不同复合材料的宏观结构及其优缺点Table 3 The macro structure of different composites and their advantages and disadvantages |

| Macro structure | Advantage | Disadvantage | ref |

|---|---|---|---|

| Fiber structure | Various preparation methods | Bad stability | 96 |

| Net structure | Good breathability | Bad stability | 101 |

| Film structure | Various structural design | Bad breathability | 104 |

5.1 纤维状结构

5.2 网状结构

图11 MXene/PU复合纤维的单股(a)和四股(b)的针织物网络结构示意图;(c)用四股MXene/PU复合纤维编织的肘套在伸直、弯曲时的照片及肘部套筒的应变传感响应曲线[101]Fig.11 Single jersey textiles knitted by using (a) single- and (b) four-ply yarn of MXene/PU composite fiber and their schematic illustrations. (c) Photos of Elbow sleeve knitted by using four-ply yarn of MXene/PU composite fiber as-knitted on an elbow at straight and bent conditions and its strain sensing response curve[101]. Copyright 2020, Wiley-VCH Verlag |

5.3 薄膜结构

6 基于柔性导电高分子复合材料应变传感器的传感机理

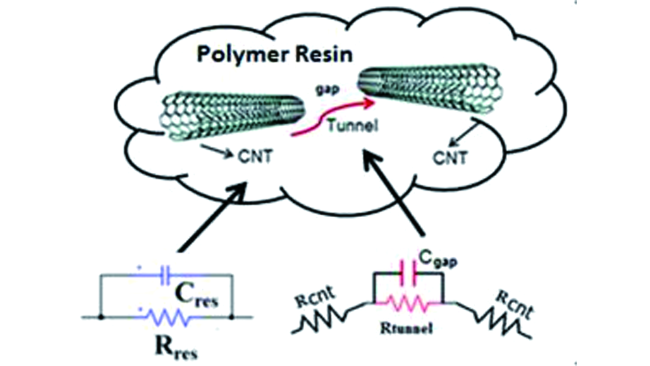

6.1 隧穿效应

6.2 分离机制

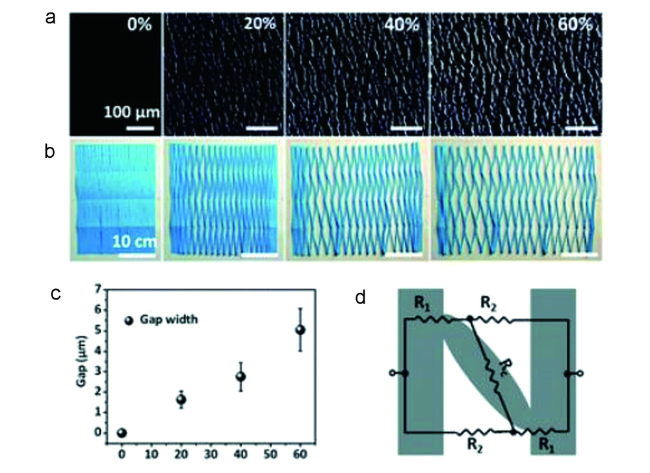

6.3 裂纹扩展

图15 CNTs薄膜/ PDMS应变传感器的裂纹扩展机理(a)将CNTs/ PDMS复合材料从0%拉伸到60%的光学图像;(b)模拟了裂纹形态从非应变状态到应变状态的变化;(c)平均间隙宽度与应变加载之间关系;(d)传感单元的电阻模型[113]Fig.15 Crack propagation mechanism of CNTs films/PDMS strain sensors. (a) Series of optical images of the CNTs films/PDMS composite being stretched from 0% to 60%; (b) Chinese paper cuttings simulating the change of crack morphology from unstrained to strained states; (c) Average gap width versus strain loading; (d) The resistance model of a sensing unit[113]. Copyright 2018, Royal Society of Chemistry |