PDF(10408 KB)

PDF(10408 KB)

PDF(10408 KB)

PDF(10408 KB)

PDF(10408 KB)

PDF(10408 KB)

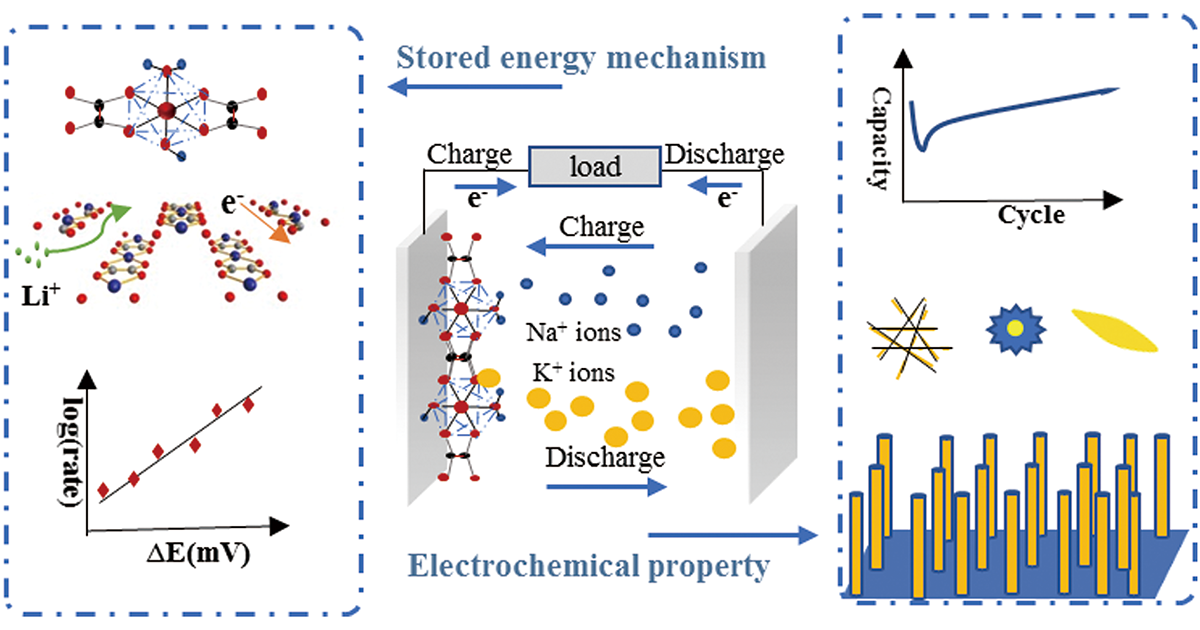

金属草酸盐基负极材料——离子电池储能材料的新选择

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Metal Oxalate-Based Anode Materials: A New Choice for Energy Storage Materials Applied in Metal Ion Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |