PDF(18847 KB)

PDF(18847 KB)

PDF(18847 KB)

PDF(18847 KB)

PDF(18847 KB)

PDF(18847 KB)

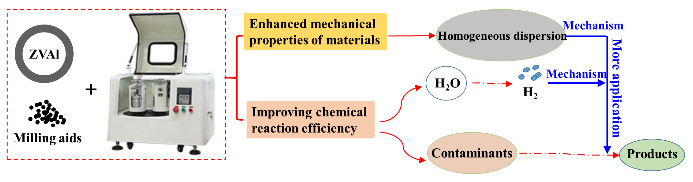

机械球磨改性零价铝的作用机制

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Modification Mechanism of Zero-Valent Aluminum by Mechanical Ball Milling

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |