PDF(23293 KB)

PDF(23293 KB)

高电压锂离子正极材料LiNi0.5Mn1.5O4高温特性

高金伙, 阮佳锋, 庞越鹏, 孙皓, 杨俊和, 郑时有

化学进展 ›› 2021, Vol. 33 ›› Issue (8) : 1390-1403.

PDF(23293 KB)

PDF(23293 KB)

PDF(23293 KB)

PDF(23293 KB)

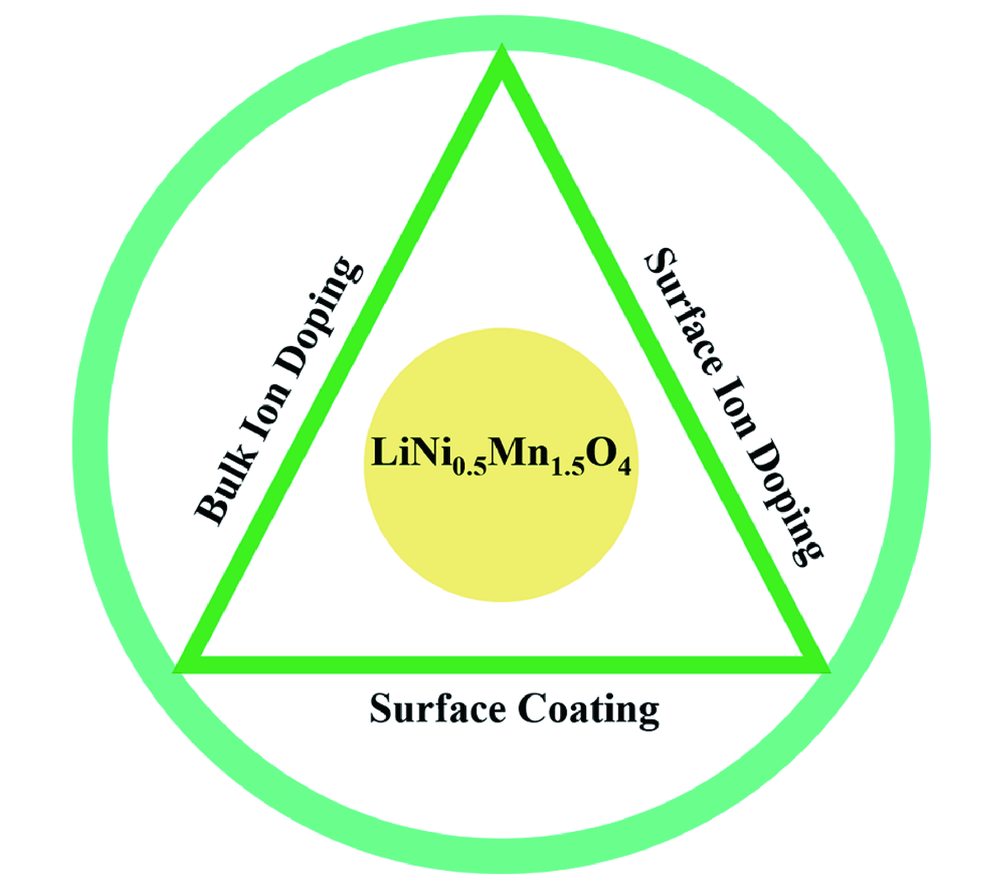

高电压锂离子正极材料LiNi0.5Mn1.5O4高温特性

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}High Temperature Properties of LiNi0.5Mn1.5O4 as Cathode Materials for High Voltage Lithium-Ion Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |