PDF(7681 KB)

PDF(7681 KB)

PDF(7681 KB)

PDF(7681 KB)

PDF(7681 KB)

PDF(7681 KB)

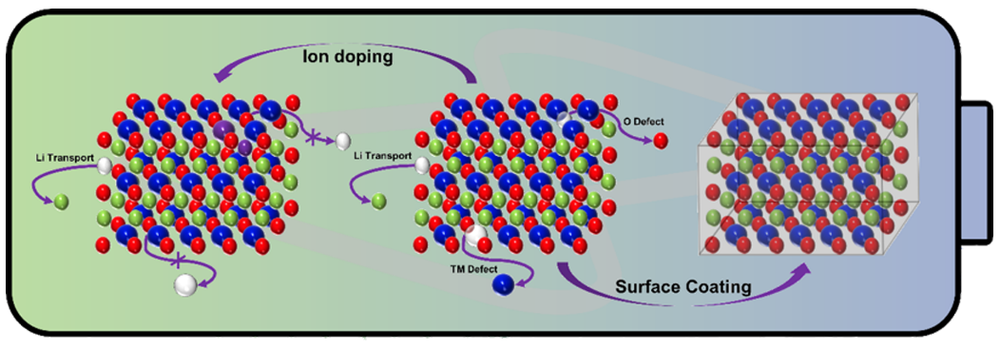

锂离子电池富锂锰基层状正极材料的稳定性

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Enhancing the Stability of Lithium-Rich Manganese-Based Layered Cathode Materials for Li-Ion Batteries Application

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |