PDF(6443 KB)

PDF(6443 KB)

PDF(6443 KB)

PDF(6443 KB)

PDF(6443 KB)

PDF(6443 KB)

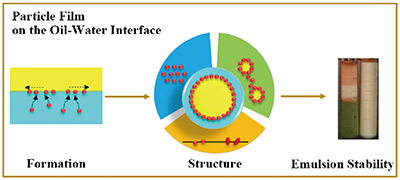

颗粒膜的结构及对乳状液稳定性的影响机制

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Structure Characterization of Particle Film and Its Role in Stabilizing Emulsion

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |