PDF(1940 KB)

PDF(1940 KB)

PDF(1940 KB)

PDF(1940 KB)

PDF(1940 KB)

PDF(1940 KB)

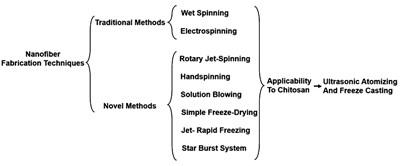

纳米纤维制备工艺进展及其对壳聚糖的适用性分析

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Nanofiber Fabrication Techniques and Its Applicability to Chitosan

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |