文章编号: 1594367899571-1028452251

文献标识码: A

用于光催化分解硫化氢制氢的金属硫化物

收稿日期:2019-12-13

要求修回日期:2020-01-17

网络出版日期:2020-07-10

基金资助

国家自然科学基金项目(U1862111)

中国科学院“西部之光”计划、四川省国际科技合作与交流项目(2017HH0030)

西南石油大学研究生科研创新基金项目(2019cxzd009)

版权

Metal Sulfide Semiconductors for Photocatalytic Hydrogen Production from Waste Hydrogen Sulfide

Received:13 Dec. 2019

rev-requestrev-request:17 Jan. 2020

Online:10 Jul. 2020

Fund

National Natural Science Foundation of China(U1862111)

Chinese Academic of Science “Light of West China” Program, the Sichuan Provincial International Cooperation Project(2017HH0030)

Graduate Student Scientific Research Innovative Project of SWPU(2019cxzd009)

Copyright

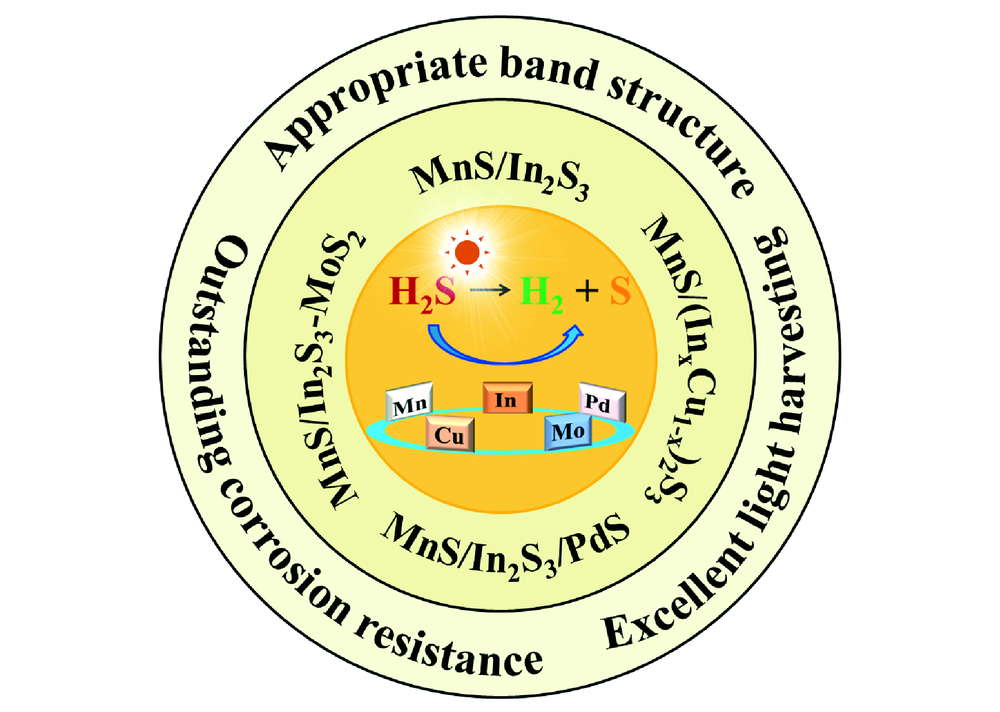

硫化氢(H2S)作为一种剧毒、恶臭的强腐蚀性气体,广泛来源于人类活动和自然界,对动植物生存和环境都具有较大的危害。光催化分解H2S制氢是一种理想的H2S处理技术,可以同时实现H2S的转移和清洁能源氢气的产生。近年来,金属硫化物由于其优异的可见光响应、恰当的能带结构和对H2S有高的稳定性,因此被广泛地应用于光催化分解H2S制氢。本文对近年来国内外金属硫化物驱动H2S资源化利用制氢领域取得的重要进展进行了概述和总结,探讨了不同反应媒介下光催化分解H2S制氢机制;特别关注了一些为实现高效稳定光催化H2S资源化利用制氢的优异调控策略;最后,对H2S资源化利用的挑战和前景进行了展望。

淡猛 , 蔡晴 , 向将来 , 李筠连 , 于姗 , 周莹 . 用于光催化分解硫化氢制氢的金属硫化物[J]. 化学进展, 2020 , 32(7) : 917 -926 . DOI: 10.7536/PC191209

Meng Dan , Qing Cai , Jianglai Xiang , Junlian Li , Shan Yu , Ying Zhou . Metal Sulfide Semiconductors for Photocatalytic Hydrogen Production from Waste Hydrogen Sulfide[J]. Progress in Chemistry, 2020 , 32(7) : 917 -926 . DOI: 10.7536/PC191209

Hydrogen sulfide(H2S), owing to the extremely toxic, malodorous and corrosive nature, is a detrimental and undesirable environmental pollutant widely generated in the petrochemical industry. How to handle H2S effectively and convert it into highly-valued products is vital. Photocatalysis is one of the most ideal routes to realize the resource utilization of H2S. Recently, metal sulphides are widely used as desirable photocatalysts for H2 production from waste H2S due to their remarkable visible-light response, proper band structure and strong resistance against H2S poisoning. Here, we summarize the current status, and challenges of this field. The photocatalytic H2S splitting mechanism are overviewed in different reaction medium. Particularly, promising strategies for highly efficient photocatalytic conversion of H2S are systematically discussed, which is aimed to inspire researchers interested in this field. Finally, some challenges in the H2S splitting process and their future research directions are outlined.

1 Introduction

2 Photocatalytic H2 production from waste H2S over metal sulfides

2.1 Binary metal sulfides

2.2 Ternary and solid-solution metal sulfides

2.3 Metal sulfide composites

3 Conclusion and outlook

Key words: metal sulfides ; photocatalytic ; hydrogen sulfide ; H2 evolution ; stability

表1 金属硫化物光催化分解H2S制氢性能对比Table 1 Comparison of hydrogen evolution over reported metal sulfide photocatalysts |

| Photocatalysts | Light source | Aqueous reaction solution | Cocatalysts/H2 activity(mmol·g-1·h-1) | Quantum yield(%) | ref |

|---|---|---|---|---|---|

| CdS/Pt | 300-W Xe, λ > 420 nm | H2S+DEA | 47.60 | 30% | 50 |

| CdS/TiO2 | 500-W Hg, λ ≥ 420 nm | H2S+1 M NaOH | Pt/9.80 | - | 31 |

| CdIn2S4 | 450-W Xe, λ ≥ 420 nm | H2S+0.5 M KOH | 6.96 | 17.1%-550 nm | 42 |

| Q-CdS-glass powder | 450-W Xe, λ ≥ 420 nm | H2S+0.5 M KOH | 3.57 | 17.5% | 17 |

| CdLa2S4 | 450-W Xe, λ ≥ 420 nm | H2S+0.5 M KOH | 5.10 | 11.6% | 45 |

| CdIn2S4 | 300-W Xe, λ ≥ 420 nm | H2S+0.5 M KOH | 6.48 | - | 44 |

| ZnIn2S4 | 300-W Xe, λ ≥ 420 nm | H2S+0.25 M KOH | 10.57 | - | 43 |

| Bi2S3 | normal solar light | H2S+0.5 M KOH | 8.88 | - | 51 |

| Fe-Zn-S solid solution | 500-W Xe, | H2S+0.5 M NaOH | 5.06 | - | 52 |

| Fe-Co-Zn-S solid solution | 500-W Xe, | H2S+0.5 M NaOH | 8.39 | 25.0%-434 nm | 53 |

| γ-MnS | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 0.02 | - | 54 |

| MnS/In2S3 | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 8.34 | 34.5%-450 nm | 32 |

| In2S3/CuS | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 14.95 | 9.3%-420 nm | 55 |

| Cd x In1- x S | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 16.35 | 26.7%-420 nm | 48 |

| MnS/(In x Cu1- x )2S3 | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 29.25 | 65.2%-420 nm | 47 |

| MnS/In2S3/PdS | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 22.7 | 34.1%-400 nm | 56 |

| MnS/In2S3-MoS2 | 300-W Xe, λ > 420 nm | H2S+0.1 M Na2S + 0.6 M Na2SO3 | 49.56 | 72%-400 nm | 57 |

图3 Pt/CdS在不同醇胺溶液中可见光光催化H2S分解性能图,反应条件:反应介质:100 mL醇胺溶液;H2S浓度: 0.30 M;催化剂用量: 0.025 g;光源:300 W Xe灯(带λ > 420 nm滤光片)[50]Fig.3 Photocatalytic H2 production over Pt/CdS(0.20 wt% Pt) in different alkanolamine solutions. Reaction conditions: volume, 100 mL; concentration of H2S, 0.30 M; catalyst, 0.025 g; light source, 300-W Xe lamp with a cutoff filter(λ > 420 nm)[50]. Copyright 2008, Elsevier |

图7 (a) Fe-Zn-S[52];(b) Fe-Co-Zn-S[53]固溶体光解H2S制氢性能图,数据为在大气压下298K每10 min测定的,反应容器中包含0.2 g溶解于50 mL pH=11的碱性H2S溶液中的光催化Fig.7 The volume of hydrogen gas photocatalytically produced as a function of irradiation time over (a) Fe-Zn-S[52]. Copyright 2018, Elsevier; (b) Fe-Co-Zn-S solid solutions (data were recorded every 10 min under atmospheric pressure at 298 K; the reaction chamber contained 0.2 g photocatalyst powder dispersed in a 50 mL H2S alkaline solution at pH=11)[53]. Copyright 2019, Elsevier |

图9 MnS/In2S3复合金属硫化物光解H2S制氢性能[32]Fig.9 Comparison of the photocatalytic activity of MnS/In2S3 samples[32]. Reaction conditions: reaction solution, Na2SO3-Na2S(0.6 mol/L-0.1 mol/L) aqueous solution(50 mL); concentration of H2S, 3 M; light source, 300 W Xe lamp with a cut off filter(λ> 420 nm). Copyright 2017, Elsevier |

图10 (a) MnS/In2S3_0.7[32];(b) In2S3/CuS长时间光催化H2S循环性能,反应条件:反应介质:50 mL Na2S-Na2SO3 (0.1 M/0.6 M) 水溶液;H2S浓度:3 M;催化剂用量:2.5 mg; 光源:300 W Xe灯(带λ > 420 nm滤光片)[55]Fig.10 (a) Long-term cycling experiments over MnS/In2S3_0.7[32]. Copyright 2017, Elsevier. (b) In2S3/CuS composite[55]. Copyright 2018, Elsevier. Reaction conditions: reaction solution, Na2S-Na2SO3 (0.1 M/0.6 M) aqueous solution (50 mL); concentration of H2S, 3 M; catalyst,2.5 mg; light source, 300 W Xe lamp with a cut off filter (λ> 420 nm) |

图11 (a) MnS/In2S3复合物在Na2S/Na2SO3反应媒介中光催化H2S分解机制[32]; (b) MnS/In2S3/PdS光催化H2S分解性能图;(c) 长期光催化H2S制氢测试,反应条件:Na2SO3-Na2S (0.6 mol/L-0.1 mol/L) 水溶液(50 mL),H2S浓度 3 M,光源: 带λ > 420 nm滤光片的300 W Xe灯[56]Fig.11 (a) Photocatalytic process of splitting H2S over MnS/In2S3 composites in Na2S/Na2SO3 reaction solution[32]. Copyright 2017, Elsevier. (b) Photocatalytic H2 production, (c)Long-team stability of over MnS/In2S3/PdS samples[56]. Copyright 2019, Elsevier. Reaction conditions: reaction solution, Na2SO3-Na2S (0.6 mol/L-0.1 mol/L) aqueous solution (50 mL); concentration of H2S, 3 M; light source, 300 W Xe lamp with a cut off filter (λ> 420 nm) |

图12 (a) MnS/In2S3/PdS复合物紫外-可见漫反射光谱图[56];(b) MnS/(In x Cu1- x )2S3光催化H2S分解性能;(c) MnS/(In x Cu1- x )2S3光催化H2S循环测试;(d) MnS/(In x Cu1- x )2S3复合物紫外-可见漫反射光谱图[47]Fig.12 (a) UV-vis DRS of MnS/In2S3/PdS samples[56]; (b) Photocatalytic H2 production performance; (c)Cycling test; (d) UV-vis DRS of MnS/(In x Cu1- x )2S3 samples[47]. Copyright 2019, Elsevier. Reaction conditions: reaction solution, Na2SO3-Na2S (0.6 mol/L-0.1 mol/L) aqueous solution (50 mL); concentration of H2S, 3 M; light source, 300 W Xe lamp with a cut off filter (λ> 420 nm) |

图13 (a) MnS/In2S3/MoS2光催化H2S分解性能;(b) MnS/In2S3/MoS2复合物形成机制[57]Fig.13 (a)Photocatalytic H2 production; (b) Formation mechanism of MnS/In2S3/MoS2 composites[57]. Copyright 2019, Elsevier Reaction conditions: reaction solution, Na2SO3-Na2S (0.6 mol/L-0.1 mol/L) aqueous solution (50 mL); concentration of H2S, 3 M; light source, 300 W Xe lamp with a cut off filter (λ> 420 nm) |

| [1] |

Kimura H . Mol. Neurobiol., 2002,26(1):13. doi: 10.1385/MN:26:1:013 b5cb2979-b341-4e12-9c94-fa4dd1451e96 http://www.springerlink.com/content/m7147830766q2420/

Hydrogen sulfide (H2S) is a well-known toxic gas with the smell of rotten eggs. Since the first description of the toxicity of H2S in 1713, most studies about H2S have been devoted to its toxic effects. Recently, H2S has been proposed as a physiologically active messenger. Three groups discovered that the brain contains relatively high concentrations of endogenous H2S. This discovery accelerated the identification of an H2S-producing enzyme, cystathionine β-synthase (CBS) in the brain. In addition to the well-known regulators for CBS, S-adenosyl-L-methionine (SAM) and pyridoxal-5′-phosphate, it was recently found that Ca2+/calmodulin-mediated pathways are involved in the regulation of CBS activity. H2S is produced in response to neuronal excitation, and alters hippocampal long-term potentiation (LTP), a synaptic model for memory. can also regulate the release of corticotropin-releasing hormone (CRH) from hypothalamus. Another H2S producing enzyme, cystathionine γ-lyase (CSE), has been identified in smooth muscle, and H2S relaxes smooth muscle in synergy with nitric oxide (NO). Recent progress in the study of H2S as a novel neuromodulator/transmitter in the brain is briefly reviewed.]]> |

| [2] |

Kabil O , Banerjee R J . Biol. Chem., 2010,285(29):21903. doi: 10.1074/jbc.R110.128363 http://www.jbc.org/lookup/doi/10.1074/jbc.R110.128363

|

| [3] |

Khan A A , Schuler M M , Prio M G , Yong S , Coppock R W , Florence L Z , Lillie L E . Toxicol. Appl. Pharm., 1990,103(3):482. doi: 10.1016/0041-008X(90)90321-K https://linkinghub.elsevier.com/retrieve/pii/0041008X9090321K

|

| [4] |

Zhang X , Tang Y , Qu S , Da J , Hao Z . ACS Catal., 2015,5(2):1053. doi: 10.1021/cs501476p https://pubs.acs.org/doi/10.1021/cs501476p

|

| [5] |

魏国齐(Wei G Q), 谢增业(Xie Z Y), 宋家荣(Song J R), 杨威(Yang W), 王志宏(Wang Z H), 李剑(Li J), 王东良(Wang D L), 李志生(Li Z S), 谢武仁(Xie W R) . 石油勘探与开发 (Petrol. Explor. Dev.), 2015,42(6):2.

|

| [6] |

于燕秋(Yu Y Q), 毛红艳(Mao H Y), 裴爱霞(Pei A X) . 天然气工业 (Nat. Gas Ind.), 2011,31(3):22. doi: 10.3787/j.issn.1000-0976.2011.03.006 3d2c8fe6-cdf7-4fbe-9d71-85738af851e6 http://www.trqgy.cn/CN/abstract/abstract11928.shtml

2S、含CO2的特点。建设处理规模120×108 m3/a的天然气净化厂,面临天然气净化难度大、硫磺储运技术和安全要求高、生产工艺及安全控制复杂等诸多技术难题。目前国内尚无百亿立方米级天然气净化以及配套硫磺成型与安全储运技术。为此,在优选评价国内外先进净化工艺的基础上,确定了适合普光气田的高含硫天然气净化工艺,并首次应用了气相固定床水解COS、中间胺液冷却、MAG-液硫脱气、特大型火炬放空、液硫湿法成型等国际先进工艺和专利技术。开发了国内首例特大型散装硫磺料仓、首例5 000 m3液硫储罐、首套硫磺流水线转运以及快速定量装车系统,实现200×104 t/a硫磺储运系统的全方位实时监控和安全运行。配套开发先进、灵活、可靠的生产过程控制与安全控制系统,确保整个净化厂处于安全、有效的受控状态。高含硫天然气净化关键技术应用于普光气田后,装置运行平稳,产品质量合格,各项安全保障到位。为其他大型高酸性气田的天然气净化提供了示范和借鉴。]]> |

| [7] |

Ma W G , Wang H , Yu W , Wang X M , Xu Z Q , Zong X , Li C . Angew. Chem. Int. Ed., 2018,57(13):3473. doi: 10.1002/anie.201713029 http://doi.wiley.com/10.1002/anie.201713029

|

| [8] |

Reverberi A P , Klemeš J J , Varbanov P S , Fabiano B . J. Clean. Prod., 2016,136:72. doi: 10.1016/j.jclepro.2016.04.139 https://linkinghub.elsevier.com/retrieve/pii/S0959652616304280

|

| [9] |

Baykara S Z , Figen E H , Kale A , Veziroglu T N . Int. J. Hydrogen Energy, 2007,32(9):1246. doi: 10.1016/j.ijhydene.2006.07.021 https://linkinghub.elsevier.com/retrieve/pii/S0360319906003673

|

| [10] |

Lagas J A , Borsboom J , Berben P H . 1988,86(41):68.

|

| [11] |

Monnery W D , Svrcek W Y , Behie L A . Can. J. Chem. Eng., 1993,71(5):711.

|

| [12] |

Zhang M , Guan J , Tu Y C , Chen S M , Wang Y , Wang S H , Yu L , Ma C , Deng D H , Bao X H . Energy Environ. Sci., 2020,doi: 10.1039/C9EE03231B. doi: 10.1039/C2EE22486K https://www.ncbi.nlm.nih.gov/pubmed/25035710

PMID: 25035710 Reaction pathways for the acid-catalyzed conversion of furfuryl alcohol (FAL) to ethyl levulinate (EL) in ethanol were investigated using liquid chromatography-mass spectrometry (LC-MS), 1D and 2D nuclear magnetic resonance (NMR) spectroscopy, and ab initio high-level quantum chemical (G4MP2) calculations. Our combined studies show that the production of EL at high yields from FAL is not accompanied by stoichiometric production of diethyl either (DEE), indicating that ethoxymethyl furan (EMF) is not an intermediate in the major reaction pathway. Several intermediates were observed using an LC-MS system, and three of these intermediates were isolated and subjected to reaction conditions. The structures of two intermediates were elucidated using 1D and 2D NMR techniques. One of these intermediates is EMF, which forms EL and DEE in a secondary reaction pathway. The second intermediate identified is 4,5,5-triethoxypentan-2-one, which is analogous to one of the intermediates observed in the conversion of FAL to LA in water (i.e. 4,5,5-trihydroxypentan-2-one). Furthermore, conversion of this intermediate to EL again involves the formation of DEE, indicating that it is also part of a secondary pathway. The primary pathway for production of EL involves solvent-assisted transfer of a water molecule from the partially detached protonated hydroxyl group of FAL to a ring carbon, followed by intra-molecular hydrogen shift, where the apparent reaction barrier for the hydrogen shift is relatively smaller in ethanol (21.1 kcal/mol) than that in water (26.6 kcal/mol). |

| [13] |

Bhirud A P , Sathaye S D , Waichal R P , Ambekar J D , Park C J , Kale B B . Nanoscale, 2015,7(11):5023. doi: 10.1039/c4nr06435f https://www.ncbi.nlm.nih.gov/pubmed/25697910

PMID: 25697910 Highly monodispersed nitrogen doped TiO2 nanoparticles were successfully deposited on graphene (N-TiO2/Gr) by a facile in-situ wet chemical method for the first time. N-TiO2/Gr has been further used for photocatalytic hydrogen production using a naturally occurring abundant source of energy i.e. solar light. The N-TiO2/Gr nanocomposite composition was optimized by varying the concentrations of dopant nitrogen and graphene (using various concentrations of graphene) for utmost hydrogen production. The structural, optical and morphological aspects of nanocomposites were studied using XRD, UV-DRS, Raman, XPS, FESEM, and TEM. The structural study of the nanocomposite shows existence of anatase N-TiO2. Further, the details of the components present in the composition were confirmed with Raman and XPS. The morphological study shows that very tiny, 7-10 nm sized, N-TiO2 nanoparticles are deposited on the graphene sheet. The optical study reveals a drastic change in absorption edge and consequent total absorption due to nitrogen doping and presence of graphene. Considering the extended absorption edge to the visible region, these nanocomposites were further used as a photocatalyst to transform hazardous H2S waste into eco-friendly hydrogen using solar light. The N-TiO2/Gr nanocomposite with 2% graphene exhibits enhanced photocatalytic stable hydrogen production i.e. approximately 5941 mumol h(-1) under solar light irradiation using just 0.2 gm nanocomposite, which is much higher as compared to P25, undoped TiO2 and TiO2/Gr nanocomposite. The enhancement in the photocatalytic activity is attributed to 'N' doping as well as high specific surface area and charge carrier ability of graphene. The recycling of the photocatalyst shows a good stability of the nanocomposites. This work may provide new insights to design other semiconductor deposited graphene novel nanocomposites as a visible light active photocatalyst. |

| [14] |

Subramanian E , Baeg J O , Lee S M , Moon S J , Kong K J . Int. J. Hydrogen Energy, 2008,33(22):6586. doi: 10.1016/j.ijhydene.2008.07.016 https://linkinghub.elsevier.com/retrieve/pii/S0360319908008392

|

| [15] |

Gurunathan K , Baeg J O , Lee S M , Subramanian E , Moon S J , Kong K J . Int. J. Hydrogen Energy, 2008,33(11):2646. doi: 10.1016/j.ijhydene.2008.03.018 https://linkinghub.elsevier.com/retrieve/pii/S0360319908002942

|

| [16] |

Qureshi N M , Shinde M D , Baeg J O , Kale B B . New J. Chem., 2017,41(10):4000. doi: 10.1039/C6NJ04012H http://xlink.rsc.org/?DOI=C6NJ04012H

|

| [17] |

Kale B B , Baeg J O , Apte S K , Sonawane R S , Naik S D , Patil K R . J. Mater. Chem., 2007,17(40):4297.

|

| [18] |

Patil S S , Patil D R , Apte S K , Kulkarni M V , Ambekar J D , Park C J , Gosavi S W , Kolekar S S , Kale B B . Appl. Catal. B: Environ., 2016,190:75. doi: 10.1016/j.apcatb.2016.02.068 https://linkinghub.elsevier.com/retrieve/pii/S0926337316301655

|

| [19] |

Zong X , Han J , Seger B , Chen H , Lu G , Li C , Wang L . Angew. Chem. Int. Ed., 2014: 53(17):4399. doi: 10.1002/anie.201400571 http://doi.wiley.com/10.1002/anie.201400571

|

| [20] |

Zong X , Chen H , Seger B , Pedersen T , Dargusch M S , McFarland E W , Li C , Wang L . Energy Environ. Sci., 2014,7(10):3347. doi: 10.1039/C4EE01503G http://xlink.rsc.org/?DOI=C4EE01503G

|

| [21] |

Luo T , Bai J , L Ji , Zeng Q , Ji Y, Qiao L, Li X, Zhou. B . Environ. Sci. Technol., 2017,51(21):12965. doi: 10.1021/acs.est.7b03116 https://www.ncbi.nlm.nih.gov/pubmed/28971667

PMID: 28971667 A novel, facile self-driven photoelectrocatalytic (PEC) system was established for highly selective and efficient recovery of H2S and simultaneous electricity production. The key ideas were the self-bias function between a WO3 photoanode and a Si/PVC photocathode due to their mismatched Fermi levels and the special cyclic redox reaction mechanism of I(-)/I3(-). Under solar light, the system facilitated the separation of holes in the photoanode and electrons in the photocathode, which then generated electricity. Cyclic redox reactions were produced in the photoanode region as follows: I(-) was transformed into I3(-) by photoholes or hydroxyl radicals, H2S was oxidized to S by I3(-), and I3(-) was then reduced to I(-). Meanwhile, H(+) was efficiently converted to H2 in the photocathode region. In the system, H2S was uniquely oxidized to sulfur but not to polysulfide (Sx(n-)) because of the mild oxidation capacity of I3(-). High recovery rates for S and H2 were obtained up to approximately 1.04 mg h(-1) cm(-1) and approximately 0.75 mL h(-1) cm(-1), respectively, suggesting that H2S was completely converted into H2 and S. In addition, the output power density of the system reached approximately 0.11 mW cm(-2). The proposed PEC-H2S system provides a self-sustaining, energy-saving method for simultaneous H2S treatment and energy recovery. |

| [22] |

Qiao L , Bai J , Luo T , Li J , Zhang Y , Xia L , Zhou T , Xu Q , Zhou B . Appl. Catal. B: Environ., 2018,238:491. doi: 10.1016/j.apcatb.2018.07.051 https://linkinghub.elsevier.com/retrieve/pii/S0926337318306593

|

| [23] |

Ma W G , Han J F , Yu W , Yang D , Wang H , Zong X , Li C . ACS Catal., 2016,6(9):6198.

|

| [24] |

Low J , Yu J , Jaroniec M , Wageh S , Al-Ghamdi A A . Adv. Mater., 2017,29(20):1601694. doi: 10.1002/adma.v29.20 http://doi.wiley.com/10.1002/adma.v29.20

|

| [25] |

Li X , Yu J , Jaroniec M . Chem. Soc. Rev., 2016,45(9):2603. doi: 10.1039/c5cs00838g https://www.ncbi.nlm.nih.gov/pubmed/26963902

PMID: 26963902 As a green and sustainable technology, semiconductor-based heterogeneous photocatalysis has received much attention in the last few decades because it has potential to solve both energy and environmental problems. To achieve efficient photocatalysts, various hierarchical semiconductors have been designed and fabricated at the micro/nanometer scale in recent years. This review presents a critical appraisal of fabrication methods, growth mechanisms and applications of advanced hierarchical photocatalysts. Especially, the different synthesis strategies such as two-step templating, in situ template-sacrificial dissolution, self-templating method, in situ template-free assembly, chemically induced self-transformation and post-synthesis treatment are highlighted. Finally, some important applications including photocatalytic degradation of pollutants, photocatalytic H2 production and photocatalytic CO2 reduction are reviewed. A thorough assessment of the progress made in photocatalysis may open new opportunities in designing highly effective hierarchical photocatalysts for advanced applications ranging from thermal catalysis, separation and purification processes to solar cells. |

| [26] |

Wan W , Zhang R , Ma M , Zhou Y . J. Mater. Chem. A, 2018,6(3):754. doi: 10.1039/C7TA09227J http://xlink.rsc.org/?DOI=C7TA09227J

|

| [27] |

Hoffmann M R , Martin S T , Choi W , Bahnemann D W . Chem. Rev., 1995,95(1):69. doi: 10.1021/cr00033a004 https://pubs.acs.org/doi/abs/10.1021/cr00033a004

|

| [28] |

Asahi R , Morikawa T , Ohwaki T , Aoki K , Taga Y . Science, 2001,293(5528):269. doi: 10.1126/science.1061051 https://www.ncbi.nlm.nih.gov/pubmed/11452117

PMID: 11452117 |

| [29] |

Schneider J , Matsuoka M , Takeuchi M , Zhang J , Horiuchi Y , Anpo M , Bahnemann D W . Chem. Rev., 2014,114(19):9919. doi: 10.1021/cr5001892 https://www.ncbi.nlm.nih.gov/pubmed/25234429

PMID: 25234429 |

| [30] |

Kudo A , Miseki Y . Chem. Soc. Rev., 2009,38(1):253. doi: 10.1039/b800489g https://www.ncbi.nlm.nih.gov/pubmed/19088977

PMID: 19088977 This critical review shows the basis of photocatalytic water splitting and experimental points, and surveys heterogeneous photocatalyst materials for water splitting into H2 and O2, and H2 or O2 evolution from an aqueous solution containing a sacrificial reagent. Many oxides consisting of metal cations with d0 and d10 configurations, metal (oxy)sulfide and metal (oxy)nitride photocatalysts have been reported, especially during the latest decade. The fruitful photocatalyst library gives important information on factors affecting photocatalytic performances and design of new materials. Photocatalytic water splitting and H2 evolution using abundant compounds as electron donors are expected to contribute to construction of a clean and simple system for solar hydrogen production, and a solution of global energy and environmental issues in the future (361 references). |

| [31] |

Jang J S , Kim H G , Borse P H , Lee J S . Int. J. Hydrogen Energy, 2007,32(18):4786. doi: 10.1016/j.ijhydene.2007.06.026 https://linkinghub.elsevier.com/retrieve/pii/S0360319907003709

|

| [32] |

Dan M , Zhang Q , Yu S , Prakash A , Lin Y , Zhou Y . Appl. Catal. B: Environ., 2017,217:530. doi: 10.1016/j.apcatb.2017.06.019 https://linkinghub.elsevier.com/retrieve/pii/S0926337317305623

|

| [33] |

Bedoya-Lora F E , Hankin A , Kelsall G H . Electrochim. Acta, 2019,314:40. doi: 10.1016/j.electacta.2019.04.119 https://linkinghub.elsevier.com/retrieve/pii/S0013468619308072

|

| [34] |

Steudel R . Top Curr. Chem., 2003,231:99.

|

| [35] |

Steudel R . Top Curr. Chem., 2003,231:127.

|

| [36] |

Pandit V U , Arbuj S S , Mulik U P , Kale B B . Environ. Sci. Technol., 2014,48(7):4178. doi: 10.1021/es405150p https://www.ncbi.nlm.nih.gov/pubmed/24597841

PMID: 24597841 6,13-Pentacenequinone (PQ), an intermediate for an organic semiconductor pentacene, was synthesized by single step solvent free solid state reaction at room temperature under ambient conditions which is hitherto unattempted. The phase purity has been confirmed by XRD and NMR. Optical study showed the absorption at 390 and 412 nm attributed to the pi-pi* and n-pi* transitions, respectively. Cyclic voltammetry indicates the semiconducting nature of PQ having a band gap of 3 eV. The photoluminescence study revealed emissions at 408 and 432 nm. Considering the good thermal stability and absorption well within visible region, wisely, PQ has been used as a photocatalyst for the hydrogen production under solar light. Surprisingly we observed the utmost hydrogen evolution i.e. 4848 mumol/h/0.1 g (quantum efficiency 6.8%). The repeatability and reusability study confirmed the stability of the photocatalyst. The confirmation of the photocatalytic effect was also confirmed using methylene blue (MB) dye degradation under natural sunlight. The observed rate constant (Kapp) for photocatalytic MB degradation was 1.60 x 10(-2) min(-1). The use of an organic photocatalyst for hydrogen production has been demonstrated for the first time. This novel organic photocatalyst can also be explored for water splitting. |

| [37] |

Chaudhari N S , Warule S S , Dhanmane S A , Kulkarni M V , Valant M , Kale B B . Nanoscale, 2013,5(19):9383. doi: 10.1039/c3nr02975a e5255d89-b329-4606-a7ab-aaf19a3fb115 http://dx.doi.org/10.1039/c3nr02975a

Nitrogen-doped TiO2 nanostructures in the form of marigold flowers have been synthesized for the first time using a facile solvothermal method. The structural analysis has shown that such an N-doped TiO2 system crystallizes in the anatase structure. The optical absorption spectra have clearly shown the shift in the absorption edge towards the visible-light range, which indicates successful nitrogen doping. The nitrogen doping has been further confirmed by photoluminescence and photoemission spectroscopy. Microscopy studies have shown the thin nanosheets (petals) of N-TiO2 with a thickness of similar to 2-3 nm, assembled in the form of the marigold flower with a high surface area (224 m(2) g(-1)). The N-TiO2 nanostructure with marigold flowers is an efficient photocatalyst for the decomposition of H2S and production of hydrogen under solar light. The maximum hydrogen evolution obtained is higher than other known N-TiO2 systems. It is noteworthy that photohydrogen production using the unique marigold flowers of N-TiO2 from abundant H2S under solar light is hitherto unattempted. The proposed synthesis method can also be utilized to design other hierarchical nanostructured N-doped metal oxides. |

| [38] |

Kale B B , Baeg J O , Yoo J S , Lee S M , Lee C W , Moon S J , Chang H . Can. J. Chem., 2005,83(6/7):527. doi: 10.1139/v05-036 http://www.nrcresearchpress.com/doi/10.1139/v05-036

|

| [39] |

Kanade K G , Baeg J O , Kong K J , Kale B B , Lee S M , Moon S J , Lee C W , Yoon S . Int. J. Hydrogen Energy, 2008,33(23):6904. doi: 10.1016/j.ijhydene.2008.08.062 https://linkinghub.elsevier.com/retrieve/pii/S0360319908011257

|

| [40] |

Kale B B , Baeg J O , Kong K J , Moon S J , Lee S M , So W W . Int. J. Energy Res., 2010,34(5):404. doi: 10.1002/er.1645 http://doi.wiley.com/10.1002/er.1645

|

| [41] |

Naman S A , Grätzel M . J. Photochem. Photobiol. A: Chem., 1994,77(2):249. doi: 10.1016/1010-6030(94)80050-2 https://linkinghub.elsevier.com/retrieve/pii/1010603094800502

|

| [42] |

Kale B B , Baeg J O , Lee S M , Chang H , Moon S J , Lee C W . Adv. Funct. Mater., 2006,16(10):1349. doi: 10.1002/(ISSN)1616-3028 http://doi.wiley.com/10.1002/%28ISSN%291616-3028

|

| [43] |

Chaudhari N S , Bhirud A P , Sonawane R S , Nikam L K , Warule S S , Rane V H , Kale B B . Green Chem., 2011,13(9):2500. doi: 10.1039/c1gc15515f 0876b96b-c1cc-4d44-bc47-519b756f7e8b http://dx.doi.org/10.1039/c1gc15515f

It is quite well-known that refineries are producing huge amount of H2S which has been used to produce sulphur and water using the well-known Claus process. This process is not an economically viable process, due to the high-cost chemical process and creates further acute environmental problems. Therefore, we have demonstrated the conversion of poisonous H2S into H-2 using an ecofriendly phocatalysis process which is a green unconventional energy source. We have investigated ecofriendly nanostructured ZnIn2S4 photocatalyst to produce hydrogen from H2S using solar light. We also demonstrate the controlled synthesis of hierarchical nanostructured ZnIn2S4 using a facile hydrothermal method. The morphologies obtained have been greatly influenced by the presence of triethylamine (TEA) with various concentrations during the reaction. Surprisingly, a highly crystalline hexagonal layer structured ZnIn2S4 was obtained instead of cubic spinel. The hierarchical nanostructure, i.e. marigold flower-like morphology, was obtained without any surfactant. The thin and transparent petals self-assembled to form the unique nanostructured marigold flower. The highly crystalline puffy marigold flowers and nanoplates/nanostrips were obtained using TEA-assisted hydrothermal synthesis. Optical study shows the band gap in the range of 2.34-2.48 eV. Considering the band gap in the visible region, ZnIn2S4 is used as photocatalyst for hydrogen production from hydrogen sulphide under solar light which is hitherto unattempted. The constant photocatalytic activity of hydrogen evolution, i.e. 5287 mu mol h(-1), was obtained using such hierarchical nanostructured ZnIn2S4 under visible light irradiation. It is noteworthy that the H-2 evolution rate obtained is much higher compared to earlier reported photocatalysts. Considering the significance of morphologies for photocatalytic application, the formation mechanism has also been furnished. The unique hierarchical nanostructured ZnIn2S4 ternary semiconductor having hexagonal layer will have potential applications in solar cells, LEDs, charge storage, electrochemical recording, thermoelectricity and other prospective electronic and optical devices. |

| [44] |

Bhirud A , Chaudhari N , Nikam L , Sonawane R , Patil K , Baeg J O , Kale B B . Int. J. Hydrogen Energy, 2011,36(18):11628. doi: 10.1016/j.ijhydene.2011.06.061 https://linkinghub.elsevier.com/retrieve/pii/S0360319911015333

|

| [45] |

Kale B B , Baeg J O , Kong K J , Moon S J , Nikam L K , Patil K R . J. Mater. Chem., 2011,21(8):2624.

|

| [46] |

Liu X , Liang X , Wang P , Huang B , Qin X , Zhang X , Dai Y . Appl. Catal. B: Environ., 2017,203:282. doi: 10.1016/j.apcatb.2016.10.040 https://linkinghub.elsevier.com/retrieve/pii/S0926337316308037

|

| [47] |

Dan M , Wei S , Doronkin D E , Li Y , Zhao Z , Yu S , Grunwaldt J D , Lin Y , Zhou Y . Appl. Catal. B: Environ., 2019,243:790. doi: 10.1016/j.apcatb.2018.11.016 https://linkinghub.elsevier.com/retrieve/pii/S092633731831066X

|

| [48] |

Dan M , Prakash A , Cai Q , Xiang J , Ye Y , Li Y , Yu S , Lin, Y , Zhou Y . Sol. RRL, 2019,3(1):1800237. doi: 10.1002/solr.v3.1 http://doi.wiley.com/10.1002/solr.v3.1

|

| [49] |

Borgarello E , Kalyanasundaram K , Grätzel M , Pelizzetti E . Helv. Chim. Acta, 1982,65(1):243. doi: 10.1002/hlca.19820650123 http://doi.wiley.com/10.1002/hlca.19820650123

|

| [50] |

Ma G , Yan H , Shi J , Zong X , Lei Z , Li C . J. Catal, 2008,260(1):134. doi: 10.1016/j.jcat.2008.09.017 https://linkinghub.elsevier.com/retrieve/pii/S0021951708003503

|

| [51] |

Kawade U V , Panmand R P , Sethi Y A , Kulkarni, M V , Apte S K , Naik S D , Kale B B . RSC Adv., 2014,4(90):49295. doi: 10.1039/C4RA07143C http://xlink.rsc.org/?DOI=C4RA07143C

|

| [52] |

Lashgari M , Ghanimati M . J. Hazard. Mater., 2018,345:10. doi: 10.1016/j.jhazmat.2017.10.062 https://www.ncbi.nlm.nih.gov/pubmed/29128722

PMID: 29128722 H2S is a corrosive, flammable and noxious gas, which can be neutralized by dissolving in alkaline media and employed as H2-source by utilizing inside semiconductor-assisted/photochemical reactors. Herein, through a facile hydrothermal route, a ternary nanostructured solid-solution of iron, zinc and sulfur was synthesized in the absence and presence of Ag-dopant, and applied as efficient photocatalyst of hydrogen fuel production from H2S media. The effect of pH on the photocatalyst performance was scrutinized and the maximum activity was attained at pH=11, where HS(-) concentration is high. BET, diffuse reflectance and photoluminescence studies indicated that the ternary solid-solution photocatalyst, in comparison to its solid-solvent (ZnS), has a greater surface area, stronger photon absorption and less charge recombination, which justify its superiority. Moreover, the effect of silver-dopant on the photocatalyst performance was examined. The investigations revealed that although silver could boost the absorption of photons and increase the surface area, it could not appreciably enhance the photocatalyst performance due to its weak influence on retarding the charge-recombination process. Finally, the phenomenon was discussed in detail from mechanistic viewpoint. |

| [53] |

Lashgari M , Ghanimati M . Chem. Eng. J., 2019,358:153. doi: 10.1016/j.cej.2018.10.011 https://linkinghub.elsevier.com/retrieve/pii/S1385894718319521

|

| [54] |

淡猛(Dan M), 张骞(Zhang Q), 钟云倩(Zhong Y Q), 周莹(Zhou Y) . 无机材料学报 (J. Inorg. Mater.), 2017,32(12):1308. doi: 10.15541/jim20170104 9edf2dc2-bacf-49e9-b5b5-5768e0fb084d http://www.jim.org.cn/CN/abstract/abstract13721.shtml

2S制氢性能进行了研究。结果表明: α, γ-MnS在可见光下都具有光解H2S制氢活性, 且相比于热力学稳定相的α-MnS (4.24 μmol/(g·h)), 亚稳态的γ-MnS (23.38 μmol/(g·h))具有更好的催化性能。相对于可见光, α, γ-MnS在全光谱下的产氢速率明显提高, 其中γ-MnS在全光谱下具有最大的光解H2S制氢活性, 其产氢速率可达 2272.69 μmol/(g·h)。值得注意的是, 在6 h的光催化测试过程中, α, γ-MnS都展示较好的抗光腐蚀能力和光催化稳定性。此外, 对α, γ-MnS光催化分解H2S制氢机理进行了分析, 通过对α, γ-MnS光电化学性质的研究, 对其光催化活性存在差异的原因进行了探讨。]]> |

| [55] |

Prakash A , Dan M , Yu S , Wei S , Li Y , Wang F , Zhou Y . Sol. Energy Mater. Sol. C., 2018,180:205. doi: 10.1016/j.solmat.2018.03.011 https://linkinghub.elsevier.com/retrieve/pii/S0927024818301144

|

| [56] |

Li Y , Yu S , Doronkin D E , Wei S , Dan M , Wu F , Ye L , Grunwaldt J D , Zhou Y . J. Catal., 2019,373:48. doi: 10.1016/j.jcat.2019.03.021 https://linkinghub.elsevier.com/retrieve/pii/S0021951719301290

|

| [57] |

Dan M , Xiang J , Wu F , Yu S , Cai Q , Ye L , Ye Y , Zhou Y . Appl. Catal. B: Environ., 2019,256:117870. doi: 10.1016/j.apcatb.2019.117870 https://linkinghub.elsevier.com/retrieve/pii/S0926337319306162

|

| [58] |

Li Z , Zhang Q , Dan M , Guo Z , Zhou Y . Mater. Lett., 2017,201:118. doi: 10.1016/j.matlet.2017.05.002 https://linkinghub.elsevier.com/retrieve/pii/S0167577X1730719X

|

| [59] |

Wang F , Wei S , Zhang Z , Patzke G R , Zhou Y . Phys. Chem. Chem. Phys., 2016,18(9):6706. doi: 10.1039/c5cp06835e https://www.ncbi.nlm.nih.gov/pubmed/26875868

PMID: 26875868 Spin-polarized DFT+U computations have been performed to investigate the role of oxygen vacancies in dissociating H2S on the rutile TiO2(110) surface. A bridged O2c atom is demonstrated to be the most energetically favorable oxygen vacancy site, which makes V(O2c) an electron donator center and induces an isolated defect level with narrowed band gaps. A H2S molecule is adsorbed dissociatively over V(O2c), but molecularly on the perfect surface. For H2S dissociation, the HS/H intermediate state reveals the best thermal stability on both defected and perfect surfaces. Moreover, potential energy surface analysis shows that V(O2c) reduces markedly the energy barriers for the paths along H2S dissociation. This indicates oxygen vacancies to be efficient trap centers for H2S dissociation, as evidenced by a significant interfacial charge transfer promoted by vacancies. This work could provide insights into the role of oxygen vacancies in facilitating the decomposition of H2S on rutile TiO2(110) surface. |

| [60] |

Wei S , Wang F , Dan M , Zeng K , Zhou Y . Appl. Surf. Sci., 2017,422:990.

|

| [61] |

Wang F , Li P , Wei S , Guo J , Dan M , Zhou Y . Appl. Surf. Sci., 2018,445:568. doi: 10.1016/j.apsusc.2018.03.198 https://linkinghub.elsevier.com/retrieve/pii/S0169433218308857

|

/

| 〈 |

|

〉 |