1 引言

2 液态金属基柔性器件材料组成

2.1 液态金属及其复合材料

| Mp (℃) | Bp (℃) | Viscocity (10-7 m2/s) | Surface tension (N/m) | Conductivity (106 S/m) | Heat conductance coefficient (W·m/K) | |

|---|---|---|---|---|---|---|

| Hg | -38.8 | 357 | 13.5 | 0.5 | 1.0 | 8.34 |

| Ga | 29.8 | 2204 | 3.24 | 0.72 | 3.7 | 29.4 |

| EGaIn | 15.5 | 2000 | 2.7 | 0.624 | 3.4 | 42.2 |

| Galinstan | -19 | 1300 | 2.98 | 0.533 | 3.1 | 44.8 |

2.2 柔性基底材料

3 液态金属基柔性导电复合材料的制备方法

3.1 被动式内部嵌入方法

3.1.1 内嵌注入封装

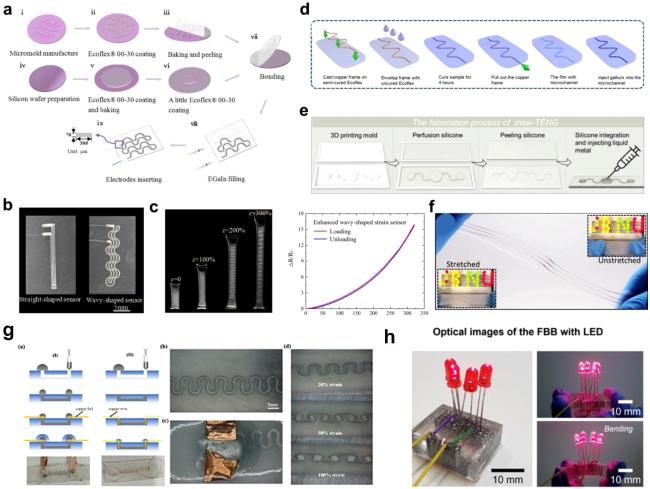

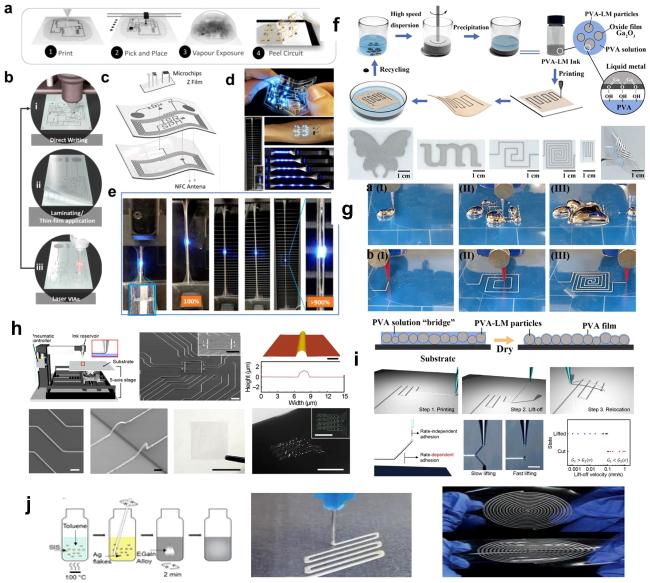

图1 (a)柔性微流控传感器制造过程的示意图[110];(b)具有直通道和波形通道的传感器的光学图像[110];(c)在不同拉伸应变下传感器照片和当从ε = 0拉伸到ε = 320%时,增强型波形传感器电阻的相对变化图[110];(d)Ecoflex中微通道的制造过程示意图[47];(e)msw-TENG的制造过程[111];(f)Ecoflex薄膜拉伸图,插图显示液体导线在拉伸状态下保持导电性[47];(g)Pan等制备的柔性电极结构与实物图[112];(h)Kim等制备的柔性面包板实物图[113]Fig.1 (a)Schematic illustration of the fabrication process of the flexible microfluidic sensor[110];(b)Optical images of sensors with the straight channel and wave-shaped channel[110];(c)Photographs of the sensor which was stretched under different tensile strains and plot of the relative change in the resistance of the enhanced wave-shaped sensor when stretched from ε = 0 to ε = 320%[110];(d)Schematic diagram of the fabrication process of microchannels in an Ecoflex[47];(e)The fabrication process of the msw-TENG[111];(f)Ecoflex film was stretched. The inset diagrams illustrate that the liquid wires maintain conductivity in the stretched state[47];(g)Structure and physical diagram of flexible electrode prepared by Pan et al.[112];(h)Actual diagram of flexible breadboard prepared by Kim et al.[113] |

3.1.2 后封装

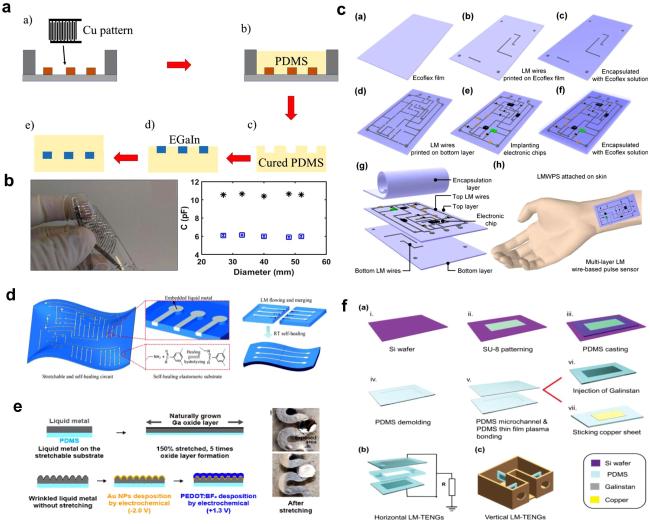

图2 (a)创建嵌入弹性体的液态金属电极的步骤[51];(b)可弯曲和拉伸的嵌入弹性体的液态金属叉指电极和不同曲率直径下的电容[51];(c)可拉伸多层LMWPS的制备步骤;(d)嵌入式自愈导体的结构和制造工艺[122];(e)镓表面氧化3D 微纳皱纹结构封装[123];(f)Munirathinam等制备的基于液态金属的摩擦电纳米发电机(LM-TENG)[124]Fig.2 (a)The procedure used to create the elastomer-embedded liquid metal electrode[51];(b)The elastomer-embedded liquid metal interdigital electrodes can be curved and stretched, capacitance under different diameters of curvature[51];(c)Fabrication process of the stretchable multilayer LMWPS[121];(d)Structure and fabrication process of the embedded self-healing conductor[122];(e)Gallium surface oxidized 3D micro-nano wrinkle structure encapsulation[123];(f)A liquid metal-based triboelectric nanogenerator (LM-TENG) prepared by Munirathinam et al[124] |

3.1.3 芯层包覆纺丝

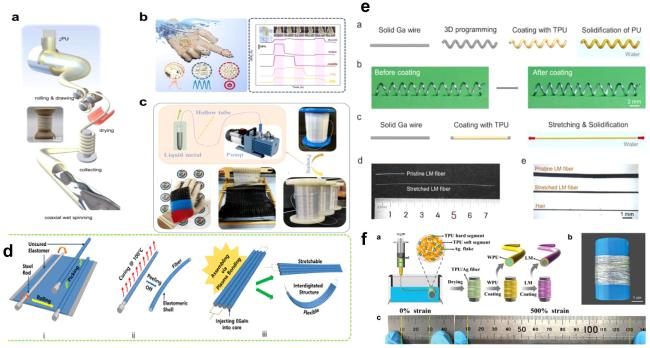

图3 (a)通过同轴湿法纺丝策略制造由聚氨酯和液态金属组成的芯-鞘纤维的示意图,插图显示了连续的纤维收集[33];(b)集成手套的数字图像,具有拉伸传感、可逆按压类型切换和低功耗电热管理功能[33];(c)基于纺织品的TENG(t-TENG)的制造程序示意图[128];(d)Lee等用液态金属芯超拉伸弹性纤维制造二维电容式传感器[130];(e)Ma等制造的可编程LM纤维[132];(f)Zhang等制造的具有二元刚软导电成分和动态补偿导电能力的可拉伸导电纤维[131]Fig.3 (a)Schematic diagram of fabrication of core-sheath fibers composed of PU and liquid metal via a coaxial wet-spinning strategy. The inset image exhibits continuous fiber collection[33];(b)Digital images of the integrated glove with stretch sensing, reversible pressing-type switching and low-power electrothermal management functions[33];(c)Schematic illustration, fabrication procedure of the textile-based TENG (t-TENG)[128];(d)a two-dimensional capacitive sensor from liquid metal-core super-stretched elastane fibers fabricated by Lee et al.[130] ;(e)Programmable LM fibers manufactured by Ma et al[132];(f)Stretchable conductive fibers manufactured by Zhang et al. with binary rigid and soft conductive components and dynamic compensation conductivity[131] |

3.2 主动式表面结构改性法

3.2.1 导电油墨及其印刷技术

3.2.1.1 导电油墨

3.2.1.2 涂布印刷型

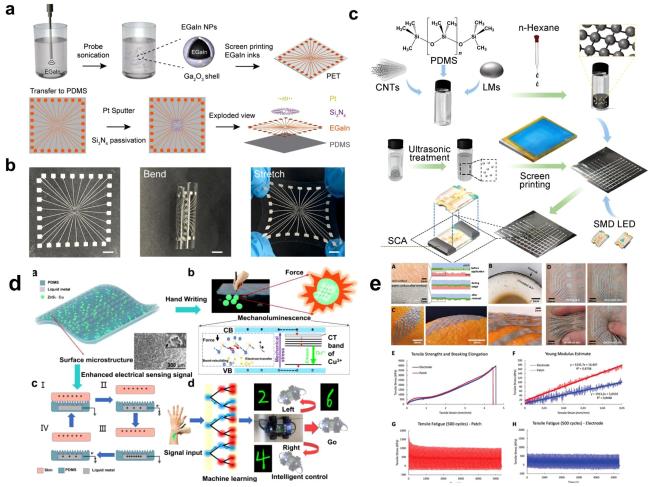

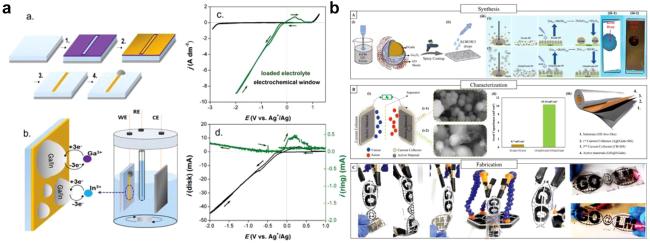

图4 (a)SEA制造示意图。EGaIn纳米颗粒通过探头超声处理和在PET基材上丝网印刷制备,在转移到PDMS基板后,通过Pt沉积和Si3N4钝化层涂层制备SEA[83];(b)具有高度灵活性(中间)和可拉伸性(右侧)的SEA快照[83],比例尺:5 mm;(c)SCA和可拉伸发光二极管(LED)屏幕的制备示意图[54];(d)Zhou等构建的一种基于微纳米结构机械发光弹性体的全自供电机械发光摩擦电传感器[148];(e)Carneiro等提出的用于制备高分辨率电生理监测的薄膜生物贴纸的通用方法[149]Fig.4 (a)Schematic illustration of fabrication of the SEA. EGaIn NPs were prepared by probe sonication and screen printed on PET substrate. After being transferred to PDMS substrate, the SEA was fabricated by Pt deposition and Si3N4 passivation layer coating[83];(b)Snapshots of the SEA with high flexibility (middle) and stretchability (right)[83]. Scale bar: 5 mm;(c)Schematics of the preparation of SCAs and stretchable light emitting diode (LED) screen[54];(d)a fully self-powered mechanical luminescent triboelectric sensor based on micro-nano structured mechanical luminescent elastomers constructed by Zhou et al.[148];(e)A general method for the preparation of thin-film biostickers for high-resolution electrophysiological monitoring proposed by Carneiro et al[149] |

3.2.1.3 直写打印型

图5 (a)芯片集成电路制造工艺[157];(b)打印多层电路的制造步骤[58];(c)无电池多层NFC电路[58];(d)具有集成传感器、微处理器和LED显示屏的软物质电路,用于温度测量、皮肤和具有多个LED的电路[157];(e)在900%的拉伸应变测试下切割并愈合的样品,以及样品在断裂前的放大图像[157];(f)PVA-LM油墨的全过程:制造、印刷和回收以及使用PVA-LM油墨打印的各种图案[56];(g)在PET膜上印刷液态金属(上)以及PVA-LM油墨(下)的过程[56];(h)液态金属的高分辨率打印[57];(i)液态金属的三维重构[57];(j)Zu等配制得到高性能液态金属导电墨水,并实现直写打印[158]Fig. 5 (a)Process for chip-integrated circuit fabrication[157];(b)Fabrication steps for printing multi-layer circuits[58];(c)A battery-free multi-layer NFC circuit[58];(d)Soft matter circuits with integrated sensors, microprocessors and LED displays for temperature measurements, skin and circuits with multiple LED[157];(e)A dully cut and healed sample under tensile strain test of 900%, and the magnified image of the sample prior to breaking[157];(f)Whole process of the PVA-LM ink: fabrication, printing, and recycling,diverse patterns printed using the PVA-LM ink[56];(g)Printing process of the liquid metal (above)and PVA-LM ink (under)on a PET film[56];(h)High-resolution printing of liquid metals[57];(i)Reconfiguration of liquid metals into 3D structures[57];(j)a high-performance liquid metal conductive ink prepared by Zu et al. and direct print printing[158] |

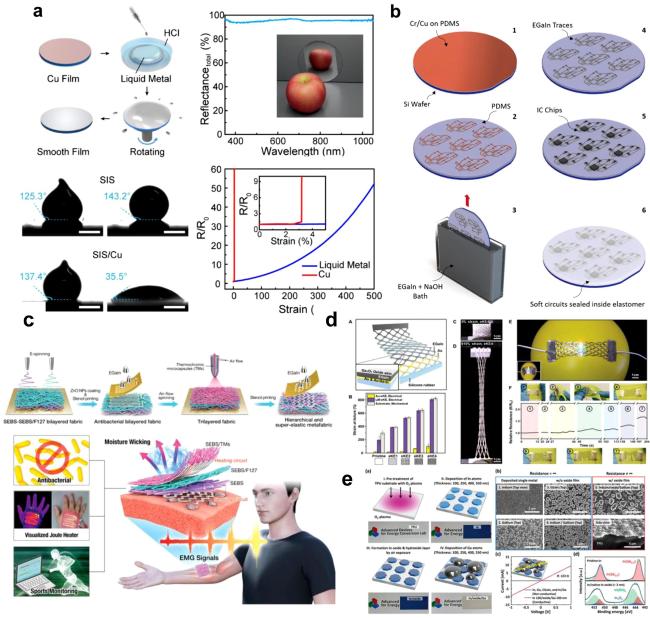

3.2.2 弹性体界面浸润性修饰

图6 (a)创建平滑均匀的液态金属膜作为反射电极的工艺流程示意图[167];(b)制造步骤示意图[168];(c)Dong等在ZnO NPs锚定的超细纤维上打印可拉伸液态金属(EGaIn)电路[169];(d)Choi等制备的基于液态金属的弹性折纸电极(LM-eKE)[170];(e)Han等制备的具备负压阻率的液态金属电极[171]Fig. 6 (a)Schematic illustration of the process flow to create a smooth and uniform liquid metal film as a reflective electrode[167];(b)Schematic illustration of the fabrication steps[168];(c)stretchable liquid metal (EGaIn) circuits printed on ZnO NPs-anchored microfibers by Dong et al.[169];(d)Liquid metal-based elastic origami electrode (LM-eKE) prepared by Choi et al.[170];(e)A liquid metal electrode with negative piezoresistivity prepared by Han et al[171] |

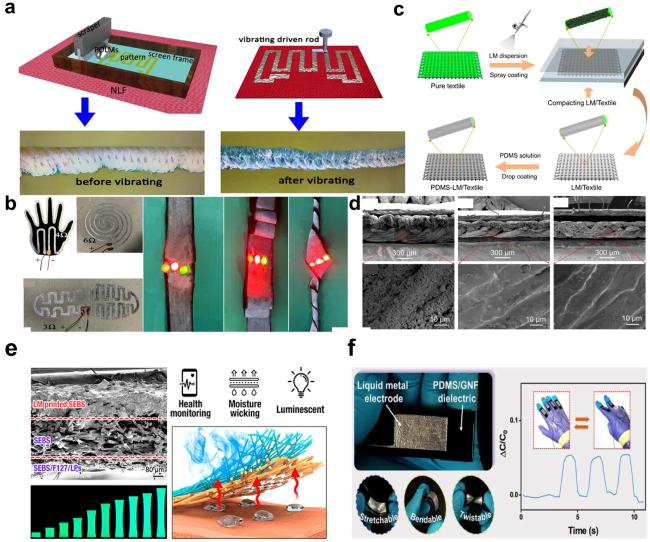

3.2.3 纤维结构浸润渗透

图7 (a)通过丝网印刷在NLF上打印POLMs的示意图,使用空气压缩机驱动杆振动前后的POLMs/NLF的光学显微照片[63];(b)使用POLM绘制图案[63];(c)PDMS-LM/纺织品的制造示意图[62];(d)机械压实PDMS-LM/织物前后的照片[62];(e)Dong等制备的SEBS超细纤维渗透液态金属电极[175];(f)Bhuyan等通过分散在聚二甲基硅氧烷(PDMS)衬底中的石墨纳米纤维(GNF)填料制备的能够区分各种手部运动的可拉伸软电容式传感器[176]Fig. 7 (a)Schematic illustration processes of printing POLMs on the NLF by screen printing and optical micrographs of POLMs/NLF before and after vibrating with an air-compressor-driven rod[63];(b)Patterning using the POLMs[63];(c)Schematic diagram for the fabrication of the PDMS-LM/Textile[62];(d)Digital photographs of the LM/Textile before and after mechanical compaction[62];(e)SEBS ultrafiber permeable liquid metal electrode prepared by Dong et al[175]; (f)a stretchable soft capacitive sensor capable of distinguishing various hand movements from graphite nanofiber (GNF) fillers dispersed in a polydimethylsiloxane (PDMS) substrate fabricated by Bhuyan et al.[176] |

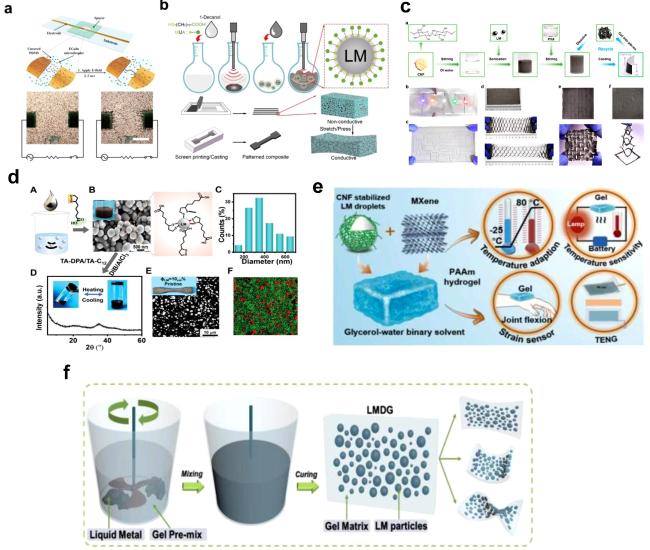

3.3 直接共混复合法

图8 (a)液态金属(EGaIn)微丝的介电泳(DEP)组装[186];(b)SBS&LM@MUA的制备方法示意图[187];(c)Li等制造的共混液态金属剪纸电极[188];(d)Pei等制备的可自愈柔性液态金属电极[189];(e)Zhang等制备的液态金属液滴分散水凝胶[190];(f)Bhuyan等制备的液态金属液滴分散凝胶[191]Fig.8 (a)Dielectric electrophoresis (DEP) assembly of liquid metal (EGaIn) microfilaments[186];(b)Schematic diagram of the preparation method of SBS&LM@MUA[187];(c)A blended liquid metal decoupage electrode manufactured by Li et al[188];(d)Self-healing flexible liquid metal electrode prepared by Pei et al.[189];(e)Liquid metal droplet dispersed hydrogel prepared by Zhang et al.[190];(f)Liquid metal droplet dispersion gel prepared by Bhuyan et al.[191] |

3.4 新式液态金属电极制备与图案化方法

3.4.1 激光热效应图案化

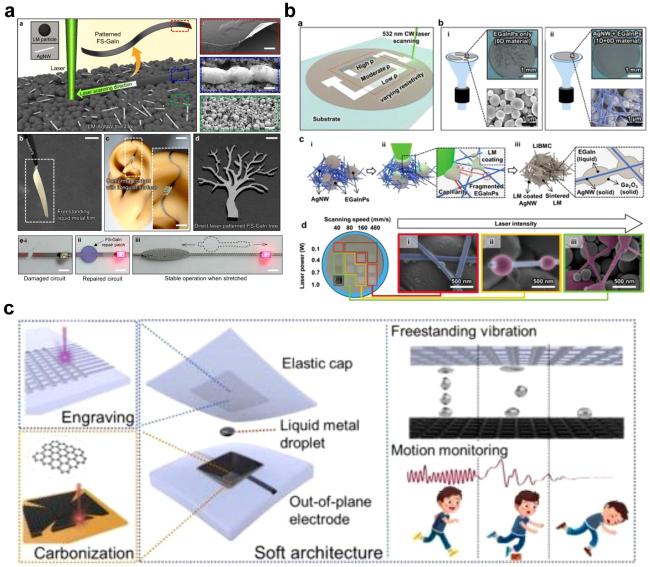

图9 (a)Kim等通过激光加工和直接图案化迹线蚀刻独立式图案化液态金属薄膜导体(FS-GaIn)[195];(b)Cho等开发的激光诱导光热反应BMC图案化[196];(c)Luo等开发的激光辅助制造设计的全软自供电振动传感器(SSVS)[197]Fig.9 (a)Free-Stand-Alone Patterned Liquid Metal Film Conductors (FS-GaIn) by Laser Processing and Direct Patterned Traces through etching by Kim[195];(b)Laser-induced photothermal reaction BMC patterning developed by Cho et al[196];(c)A fully soft self-powered vibration sensor (SSVS) designed for laser-assisted manufacturing developed by Luo et al.[197] |

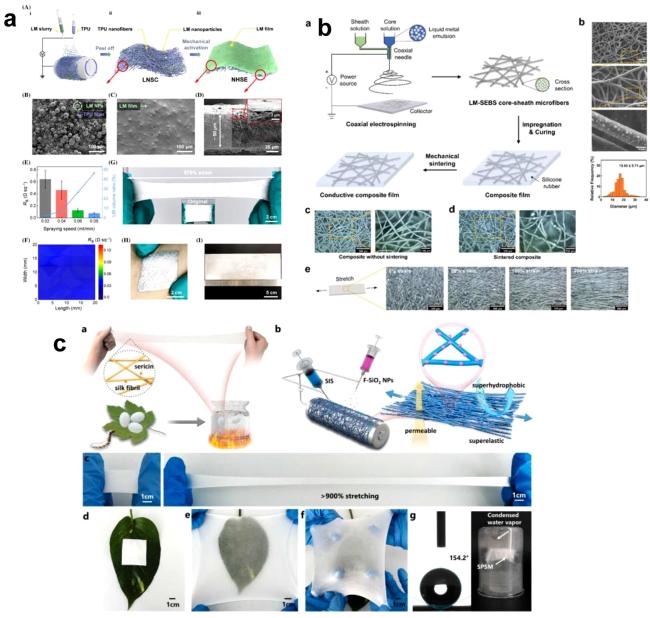

3.4.2 静电同步纺丝

图10 (a)Cao等使用静电纺丝制造的一种基于纳米液态金属的高鲁棒可拉伸电极(NHSE)[25];(b)Ma等合成的嵌入液态金属纤维网络的轻质高导电复合材料[198];(c)Li等通过苯乙烯-异戊二烯(SIS)嵌段共聚物的同步静电纺丝和氟化SiO2纳米颗粒的电喷涂制备的全向超弹性渗透性和超疏水性的微纤维膜(SPSM)[199]Fig.10 (a)a nano-liquid metal-based highly robust stretchable electrode (NHSE) using electrospinningfabricated by Cao et al.[25];(b)A lightweight, highly conductive composite material embedded in a network of liquid metal fibers synthesized by Ma et al.[198];(c)Omnidirectional hyperelastic permeable and superhydrophobic microfiber membranes (SPSMs) prepared by Li et al. by simultaneous electrospinning of styrene-isoprene (SIS) block copolymers and electrospraying of fluorinated SiO2 nanoparticles[199] |