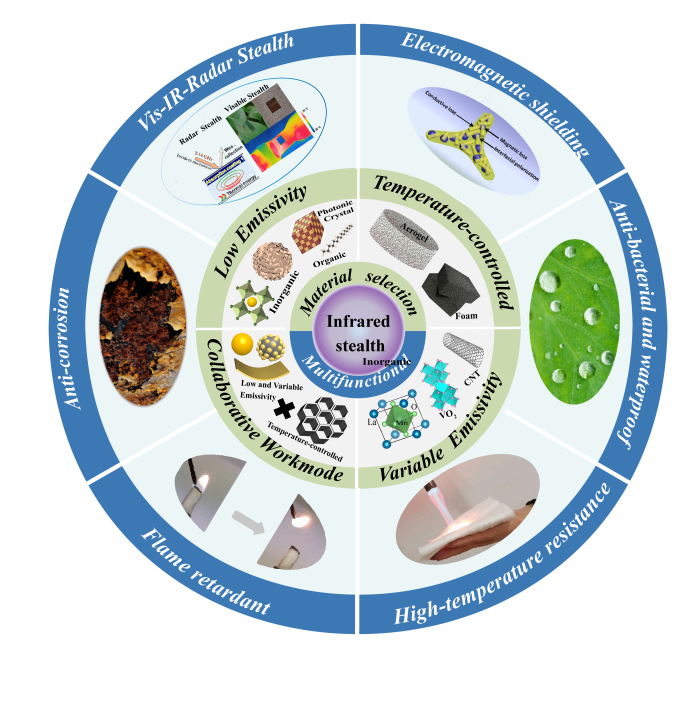

1 引言

2 红外隐身机理

3 红外隐身材料的选择及性能调控

3.1 低发射率材料

3.1.1 无机低发射率材料

3.1.2 有机低发射率材料

3.1.3 有机-无机低发射率材料

3.1.4 光子晶体

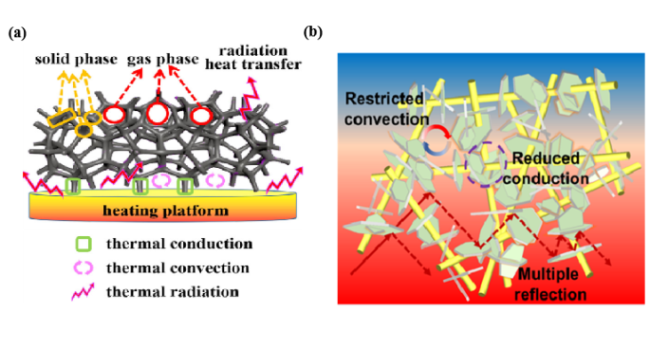

3.2 温度控制型材料

3.2.1 隔热材料

3.2.2 相变材料

3.3 可变发射率材料

3.3.1 电致变发射率材料

3.3.2 热致变发射率材料

3.4 协同工作模式材料

表1 红外隐身材料的优缺点Table 1 Advantages and disadvantages of infrared stealth materials |

| Classify | Material | Advantage | Disadvantage | Ref | ||

|---|---|---|---|---|---|---|

| Low Emissivity | Inorganic | Metal (Au、Ag、Cu、Al) | Good conductivity and low emissivity | It is easy to corrode, has a strong metallic luster, and is difficult to be compatible with visible light | 6⇓⇓⇓~10 | |

| Semiconductor (ATO、ZAO、ITO) | Corrosion-resistant, bandgap and structure can be adjusted, and it can be used in a wide range of applications | High emissivity | 13⇓~15 | |||

| Organic | Conducting polymers | Excellent electrical conductivity | Less research work | 17,18,20 | ||

| High infrared transparent polymers | Weak infrared absorption group | High emissivity | 21 | |||

| Organic-inorganic | Excellent mechanical properties; Low emissivity | Many influencing factors | 22⇓⇓⇓~26 | |||

| Photonic crystals | Adjustable bandgap | The high cost of preparation does not allow large-scale use | 28,29,32,33 | |||

| Temperature-controlled materials | Thermal insulation | Effective, with a wide range of applications | The preparation process is complex, the thickness is large, and the temperature control range is limited | 38,40⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓~53 | ||

| Phase change | VO2 | The amount of change is large, and the phase change temperature is adjustable | The color is blue-black, which is difficult to achieve compatibility with visible light and stealth; It is easy to oxidize to the toxic oxide V2O5 at high temperatures | 58⇓⇓~61 | ||

| PW | Stable performance, the change in phase change temperature and latent heat of phase change is small | Adding too much PW can lead to a decrease in mechanical properties | 63 | |||

| MCPCM | Improve the leakage problem of solid-liquid phase change materials | Single core material and expensive | 64 | |||

| Variable emissivity material | Electro-emissivity materials | The emissivity can be adjusted in a wide range | There is additional energy consumption for the impressed load | 66⇓~68 | ||

| Thermotropic emissivity materials | No external load is required, no energy consumption is required, and it varies according to its own surface temperature | The response sensitivity is slower, and the emissivity can be adjusted in a small range | 70⇓~72 | |||

| Collaborative work mode material | Temperature control, low emissivity | It solves the poor thermal insulation performance of low emissivity materials; High emissivity of temperature-controlled materials and problems with heat build-up | There are few studies on materials where temperature and emissivity can change | 73⇓⇓~76 | ||

| Temperature control, variable emissivity | Temperature and emissivity can be adjusted for a wider range of applications | 77 | ||||

4 多功能红外隐身材料的设计及应用

4.1 多波段隐身

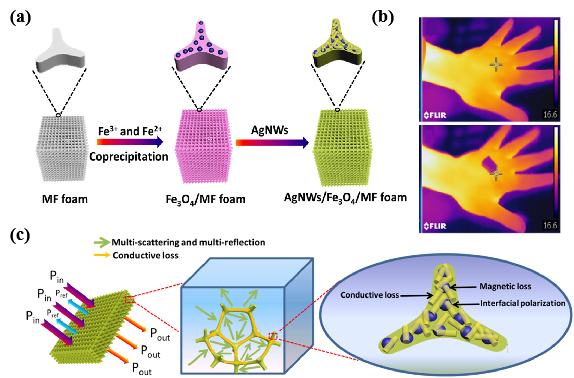

4.1.1 雷达红外兼容隐身

表2 雷达红外兼容隐身材料性能参数Table 2 Performance parameters of radar infrared compatible stealth materials |

| Sample | Emissivity | Electromagnetic parameters | Ref | ||||

|---|---|---|---|---|---|---|---|

| 3~5 μm | 8~14 μm | RLmin (dB) | EAB (GHz) | RCS (dB·m2) | Thickness (mm) | ||

| ITO-x | 0.62 | 0.67 | -40.4 | 4.88 | - | 2.8 | 14 |

| Al@RGO | - | 0.62 | -46.11 | 4.88 | - | 2 | 79 |

| Al/CIP-PU | 0.281 | - | -40 | 6.6 | - | 1.24 | 80 |

| CuS/ZnS/rGO | 0.694 | 0.577 | -28 | 6.38 | 2 | 26.3 | 81 |

| Au @MCHSs/CA-2 | 0.525 | - | -55.9 | 16 | 21.5 | 1.8 | 82 |

| CuS@rGO | 0.7 | 0.6 | -60.3 | 8.44 | 53.3 | 2.8 | 84 |

| PEDOT:PSS@melamine | 0.788 | 0.757 | -57.57 | 10.52 | 17.68 | 5 | 85 |

| HMCS@f-Fe2O3-x | 0.212 | 0.508 | -34.16 | 4.8 | - | 2.4 | 86 |

4.1.2 可见光红外兼容隐身

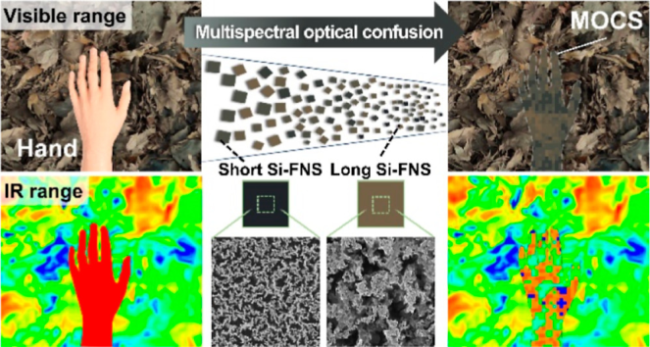

4.1.3 可见-红外-雷达兼容隐身

4.2 电磁屏蔽性能

4.3 抗菌防水性能

4.4 耐高温性能

4.5 防腐蚀性能

4.6 阻燃性能

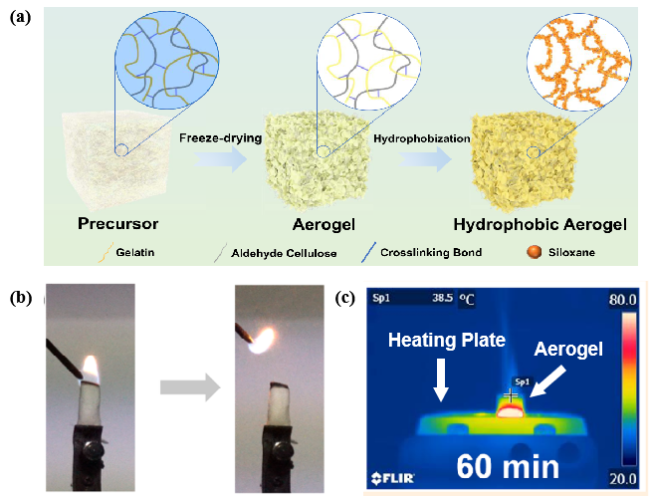

图7 (a)HGC气凝胶制备的示意图;(b)灭火过程中,HGC气凝胶的氧浓度为28.2%;(c)HGC气凝胶放置在80 ℃的加热平台上60 min红外热成像图[100]Fig. 7 (a) Schematic diagram of the HGC aerogel formulation; (b) Extinguishing process of the HGC aerogel in the oxygen concentration of 28.2%; (c) HGC aerogel was placed on a heating platform at 80 ℃ for 60 min infrared thermography[100] |