1 引言

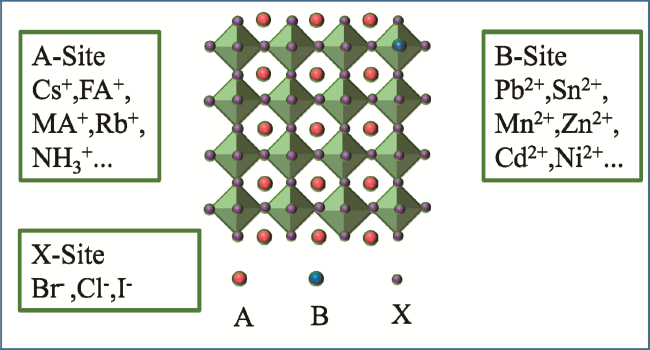

2 准二维钙钛矿概述

图2 (a) 间隔阳离子从<100>晶面将三维钙钛矿切割成层状钙钛矿的结构示意图[17];(b) RP和DJ相层状钙钛矿的晶体结构(n = 3)[17];(c) ACI相层状钙钛矿的晶体结构(n = 1,2,3)Fig. 2 (a) Structure derivation of a layered perovskite with spacer cations cutting the 3D perovskite from the <100> plane[17], Copyright 2019, American Chemical Society; (b) crystal structures of RP and DJ phase layered perovskites (n = 3)[17], Copyright 2019, American Chemical Society; (c) crystal structures of layered perovskite of ACI phase (n = 1, 2, 3). |

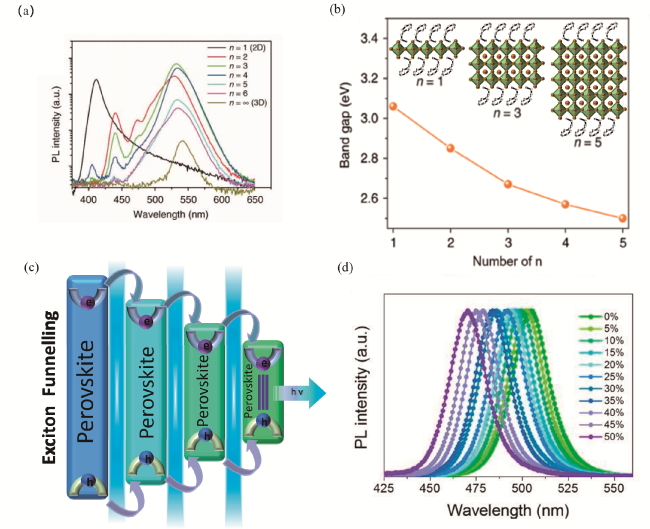

图3 (a) 不同n值的PEA2(FAPbBr3)n−1PbBr4的PL光谱[22];(b) Q2DPe的带隙,插图是n=1,3,5的准2D的钙钛矿的原子模型[23];(c) 小n相Q2DPe到大n相Q2DPe之间电荷转移或激子漏斗的能带图;(d) 不同氯化物含量的一系列准二维PBABr:CsPbBrxCl3−x 钙钛矿薄膜的归一化PL光谱[24]Fig. 3 (a) PL spectra of PEA2(FAPbBr3)n−1PbBr4 with different n values[22], Copyright 2018, Nature Publishing Group; (b) band gaps of quasi-2D perovskites, illustrated as atomic models of quasi-2D perovskites with n=1, 3, and 5[23], Copyright 2019, Wiley-Blackwell; (c) energy band diagram of charge transfer or funneling of excitons between Q2DPe of small n to large n phase; (d) normalized PL spectra for a series of quasi-2D PBABr:CsPbBrxCl3−x perovskite films with different chloride content[24], Copyright 2019, American Chemical Society. |

3 准二维蓝光钙钛矿的研究进展

3.1 组分工程

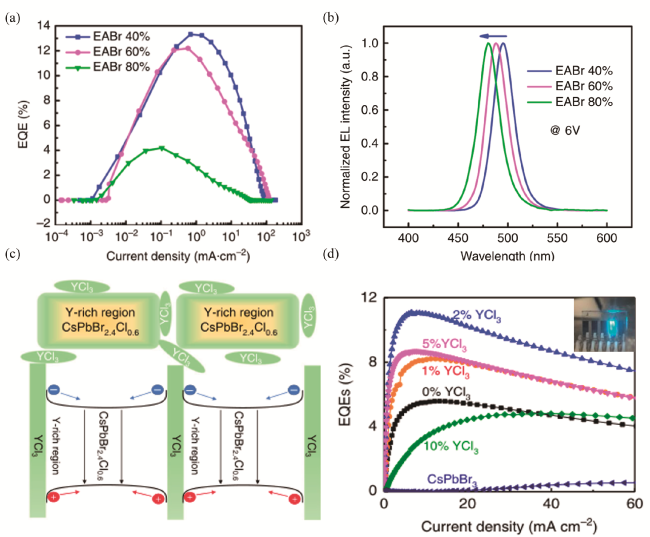

图4 (a) PEA2(Cs1−xEAxPbBr3)2PbBr4钙钛矿LED的外量子效率(EQE)与电流密度的关系[15];(b) PEA2(Cs1−xEAxPbBr3)2PbBr4钙钛矿LED的归一化电致发光(EL)光谱[15];(c) CsPbBr3: PEACl:YCl3薄膜辐射复合示意图[30];(d) 不同YCl3含量PeLEDs的EQE曲线。插图为点亮的PeLEDs照片[30]Fig. 4 (a) Characterization of external quantum efficiency (EQE) versus current density of PEA2(Cs1−xEAxPbBr3)2PbBr4 perovskite LED[15], Copyright 2020, Nature Publishing Group; (b) normalized electroluminescence (EL) spectra of PEA2(Cs1−xEAxPbBr3)2PbBr4 PeLED[15], Copyright 2020, Nature Publishing Group; (c) schematic illustration of the yttrium distribution and radiation recombination within the CsPbBr3:PEACl:YCl3 thin-film[30], Copyright 2019, Nature Publishing Group; (d) EQE curves of PeLEDs with different YCl3 percentages. Inset shows the digital photographic image of the operating PeLED[30], Copyright 2019, Nature Publishing Group. |

3.2 膜层工艺优化

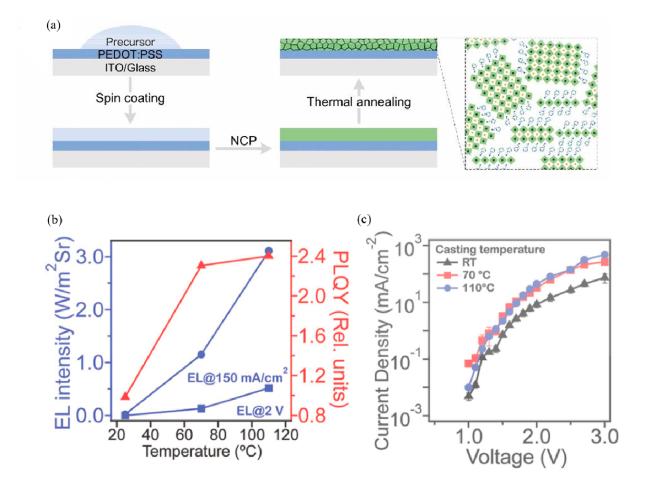

图5 (a) NCP法制备准二维钙钛矿膜层示意图[32];(b) 固定电流密度和电压下(BA)2(MA)2Pb4I13的EL强度和PLQY[36];(c) 不同温度下(BA)2(MA)2Pb4I13的J-V特性曲线[36]Fig. 5 (a) Schematic diagram of quasi-two-dimensional perovskite film prepared by NCP method[32], Copyright 2019, Royal Society of Chemistry; (b) EL intensity as a function of casting temperature at a fixed current density and fixed voltage and PLQY as a function of casting temperature for (BA)2(MA)2Pb4I13(Pb4) LEDs[36], Copyright 2018, Wiley-Blackwell; (c) J-V characteristic curves for LEDs using (BA)2(MA)2Pb4I13 casted by different temperatures[36], Copyright 2018, Wiley-Blackwell. |

图6 (a) 电流密度和亮度随电压变化的特征曲线[37];(b) EQE与电流密度的关系[37];(c) 混合卤化物钙钛矿的相分离[11]; (d) 准二维PeLEDs的三明治夹层结构Fig. 6 (a) Current-voltage-luminance characteristic curves[37], Copyright 2020, Nature Publishing Group; (b) characterization of EQE versus current density[37], Copyright 2020, Nature Publishing Group; (c) phase segregation of mixed-halide perovskites [11], Copyright 2022, Nature Publishing Group; (d) the sandwich-like interlayer structure of quasi-2D PeLEDs |

表1 蓝色和天蓝色Q2D PeLEDs的性能参数总结Table 1 Summary of performance parameters of blue and sky-blue Q2D PeLEDs |

| Perovskite material | Device structure | EL Peak (nm) | EQE (%) | Vt/(V) | Ref |

|---|---|---|---|---|---|

| PEA2Cs1.6MA0.4Pb3Br10 treated with DPPOCl | ITO/PEDOT:PSS:PFI/Q2DPe/TPBi/LiF/Al | 479 | 5.2 | - | 14 |

| PEA2(Rb0.6Cs0.4)Pb3Br10 | ITO/PEDOT:PSS/Q2DPe/TmPyPB/LiF/Al | 475 | 1.35 | 3 | 15 |

| (PEA)2PbBr4 | ITO/PEDOT:PSS/2D perovskite/TPBi/Ca/Al | 410 | 0.04 | 2.5 | 18 |

| P-PDA,PEACsn−1PbnBr3n+1 | ITO/PVK/PFI/Q2DPe/3TPYMB/Liq/Al | 465 | 2.6 | - | 19 |

| PEACl:CsPbBr3:YCl3 | ITO/TB(MA)/Q2DPe/TPBi/LiF/Al | 488 | 13.5% | 6 | 38 |

| CsPbBr3:PEACl:YCl3 | ITO/PEDOT:PSS/PVK/Q2DPe/TPBi/LiF/Al | 485 | 11 | 3 | 30 |

| PEA2Csn−1Pbn(Br/Cl)3n+1 | ITO/PEDOT:PSS/Q2DPe/TPBi/LiF/Al | 480 | 5.7 | 3.2 | 37 |

| (Cs/Rb/FA/PEA/K)Pb(Cl/Br)3 | ITO/LiF/Q2DPe/LiF/Bphen/LiF/Al | 484 | 2.01 | -- | 39 |

| EA2(MA)n−1PbnBr3n+1 | ITO/PEDOT:PSS/Q2DPe/TmPyPB/CsF/Al | 485 | 2.6 | 3.4 | 42 |

| OLA2MAn−1PbnBr3n+1 | ITO/PEDOT:PSS/PVK/Q2DPe/TPBi/LiF/Al | 456 | 0.0046 | 3.4 | 43 |

| BA2MA2Pb3Br7Cl3 | ITO/PEDOT:PSS/Poly-TPD /Q2DPe/TPBi/LiF/Al | 468 | 0.01 | 5.2 | 44 |

| POEA2MAn−1PbnBr3n+1 | ITO/PEDOT:PSS/Q2DPe/TPBi/Ba/Al | 480 | 1.1 | 3.6 | 45 |

| BA2Csn−1Pbn(Br/Cl)3n+1 | ITO/PEDOT:PSS/Q2DPe/TPBi/Al | 487 | 6.2 | 4.5 | 46 |

| PBA2Csn−1Pbn(Br/Cl)3n+1 | ITO/NiOx/LiF/Q2DPe/TPBi/LiF//Al | 490 | 0.52 | - | 24 |

| (IPA:PEA)2(MA:Cs)n−1Pbn Br3n+1 | ITO/PEDOT:PSS/Q2DPe/TPBi/LiF/Al | 490 | 1.9 | 5 | 47 |

| BA2DMA1.6Cs2Pb3Br11.6 | ITO/PEDOT:PSS or NiOx/Q2DPe/TPBi/LiF/Al | 490 | 2.4 | 3.3 | 48 |

| PEA2DMA1.2Cs2Pb3Br11.2 | ITO/PEDOT:PSS or NiOx/Q2DPe/TPBi/LiF/Al | 499 | 1.58 | 4.4 | 48 |

| (PEA:NPA)Csn−1PbnBr3n+1 | ITO/poly(N-vinylcarbazole)/PVK/Q2DPe/ PO-T2T/Liq/Al | 485 | 2.62 | 2.6 | 49 |

| (PBABr):(Cs/FA/MA)Br:PbBr2 | ITO/PEDOT: PSS/Q2DPe/PO-T2T/LiF/Al | 465 | 2.34 | 2.8 | 50 |

| PBA2(FACs)n−1PbnBr3n+1 | ITO/NiOx/TFB/PVK/Q2DPe/TPBi/LiF/Al | 483 | 9.5 | 3.3 | 51 |