Contents

1 引言

2 超疏水表面摩擦学理论基础

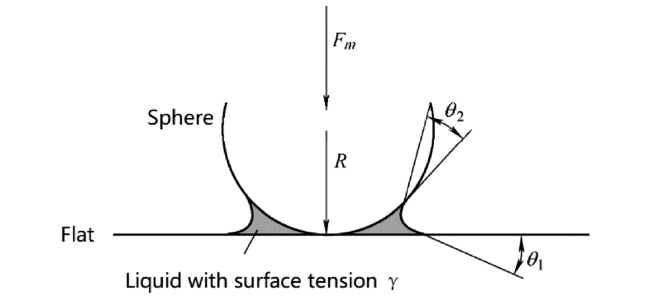

2.1 超疏水表面摩擦性能的理论分析

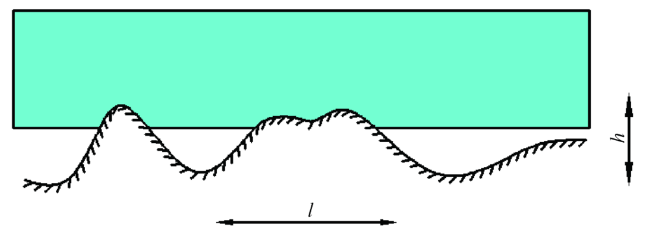

2.2 超疏水表面耐磨性能的理论分析

3 超疏水表面摩擦性能的研究现状

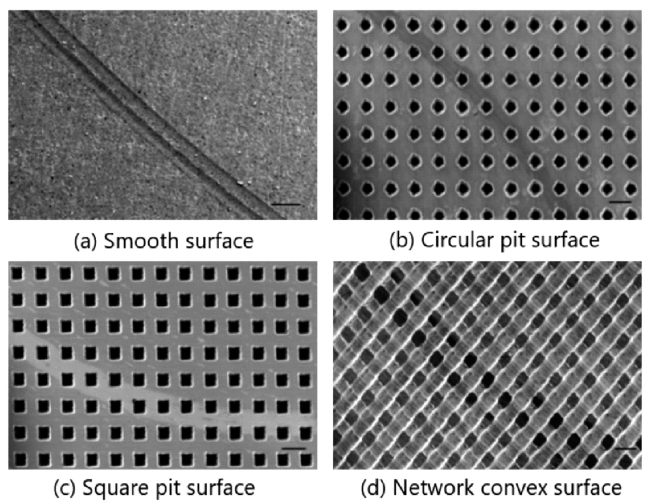

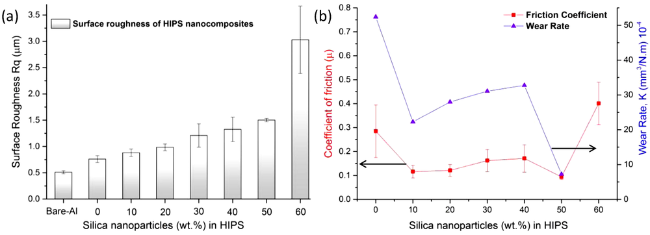

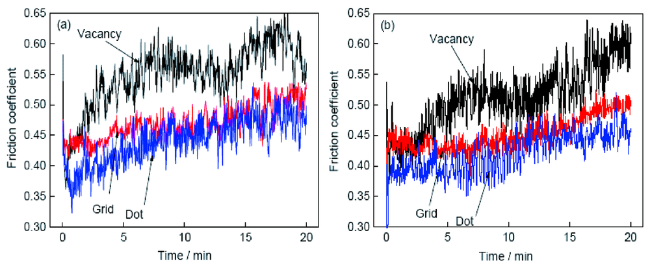

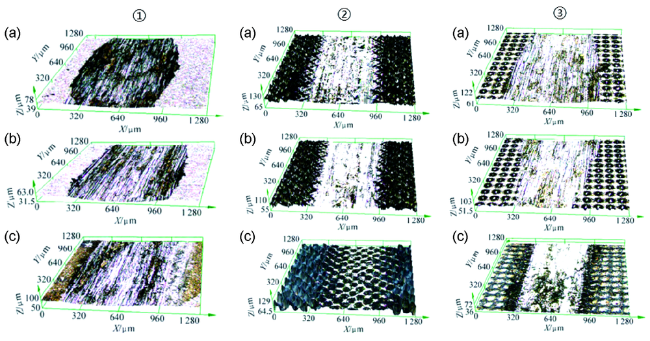

3.1 表面结构和粗糙度对超疏水表面摩擦性能的影响

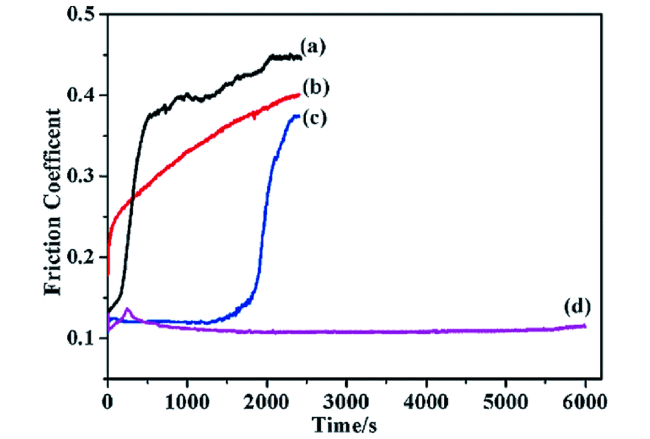

3.2 干摩擦状态下的超疏水表面摩擦性能研究

3.3 不同润滑介质状态下的超疏水表面摩擦性能研究

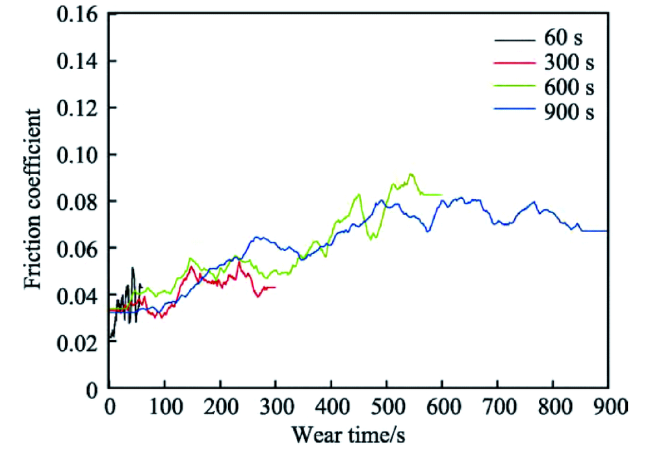

3.4 滑动速度和摩擦时间对超疏水表面摩擦性能的影响

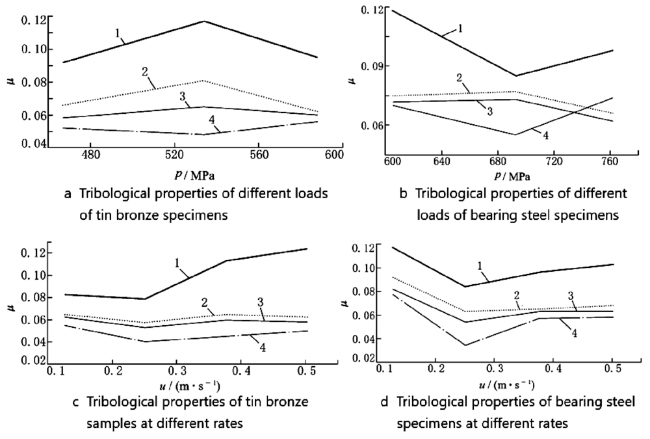

图9 锡青铜和轴承钢试样的摩擦系数随载荷(a、b)和滑动速度(c、d)的变化情况。1代表光滑表面,2、3和4分别代表微结构直径与相邻微结构中心距之比为1∶3、1∶2和1∶4的表面[53]Fig.9 The friction coefficient of tin bronze and bearing steel samples varies with loading(a, b) and sliding speed(c, d). Where, 1 representing smooth surface, 2, 3 and 4 representing surface whose ratio of microstructure diameter to the center distance of adjacent microstructures is 1∶3, 1∶2 and 1∶4, respectively[53] |

4 耐磨超疏水表面的研究现状

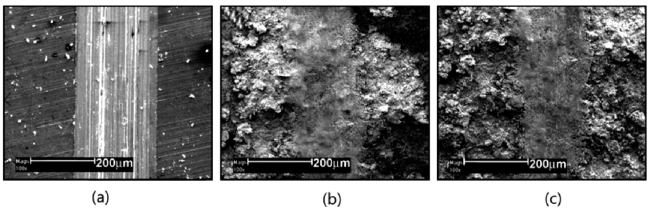

4.1 通过减轻黏着磨损来增强超疏水表面的耐磨性

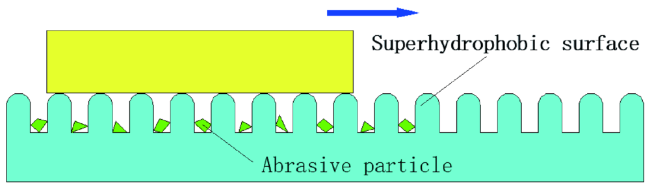

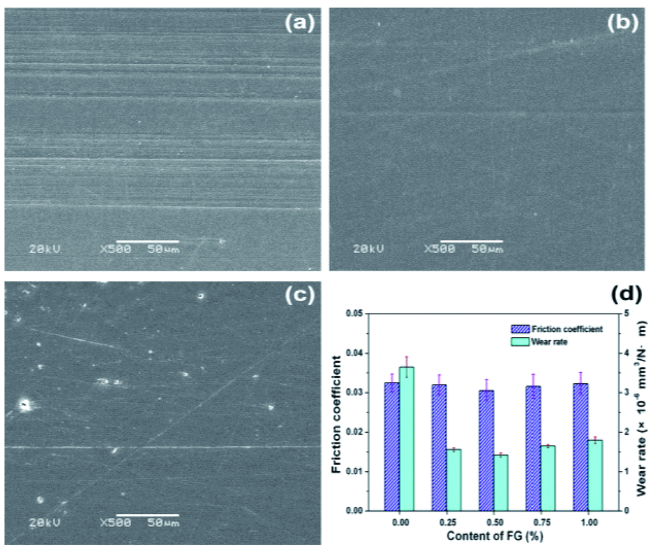

4.2 通过减轻磨粒磨损来增强超疏水表面耐磨性

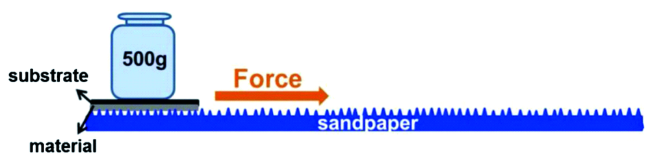

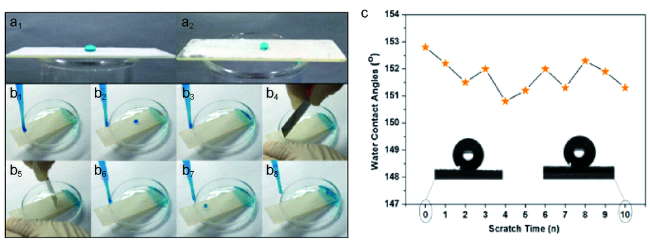

4.3 超疏水表面耐磨性的测量方法

表1 超疏水表面摩擦学性能测试常用的实验条件Table 1 Experimental conditions commonly used for testing the tribological properties of superhydrophobic surfaces |

| Measurement methods | FL/N | FV/mm/s | T/℃ | RH/% | ref |

|---|---|---|---|---|---|

| UMT | 2/3/4 | - | 23~27 | - | 53 |

| UMT | 0.5 | 10 | - | 40 | 56 |

| UMT | 0.060 | 30 | 20~25 | 25~30 | 58 |

| UMT | 0.5 | 5 | - | - | 59 |

| UMT | 3 | 10 | - | - | 60 |

| UMT | 0.050 | 3 | RT | 40~45 | 64 |

| UMT | - | 4 | RT | 40~50 | 66 |

| UMT | 0.98 | 25 | 25 | - | 75 |

| UMT | 3~15 | 0.01 | - | - | 76 |

| UMT | - | - | RT | 40~50 | 72 |

| Wear test of 600 mesh sandpaper | 1 | 10 | - | - | 77 |

| Wear test for 1000 mesh sandpaper | 10 | - | RT | - | 74 |

| Emery paper abrasion(800 mesh) | 1 | - | - | - | 78 |

| knife-scratch test | 5 | - | - | - | 79 |

| ball-on-flat micro tribometer | 0.040 | 3 | - | - | 71 |

| HSR-2 M test machine | 5 | - | RT | 40~50 | 63 |

| ball-on-plate configuration | 0.1/0.5 | - | 20 | 40~50 | 70 |

| Micro-Combi tester | 1 | - | 20 | 40~50 | 55 |

Note: FL-Friction Load, FV-Friction Velocity, RT-Room Temperature, RH-Relative humidity |