PDF(1787 KB)

PDF(1787 KB)

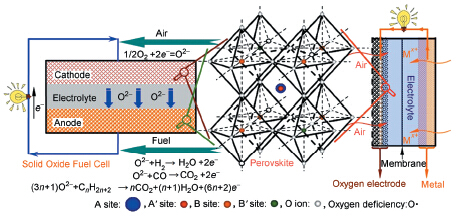

钙钛矿型氧化物的制备及其在固体氧化物燃料电池和金属-空气电池中的应用

庄树新, 吕建先, 路密, 刘翼民, 陈晓彬

化学进展 ›› 2015, Vol. 27 ›› Issue (4) : 436-447.

PDF(1787 KB)

PDF(1787 KB)

PDF(1787 KB)

PDF(1787 KB)

钙钛矿型氧化物的制备及其在固体氧化物燃料电池和金属-空气电池中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation and Applications of Perovskite-Type Oxides as Electrode Materials for Solid Oxide Fuel Cell and Metal-Air Battery

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |