PDF(793 KB)

PDF(793 KB)

PDF(793 KB)

PDF(793 KB)

PDF(793 KB)

PDF(793 KB)

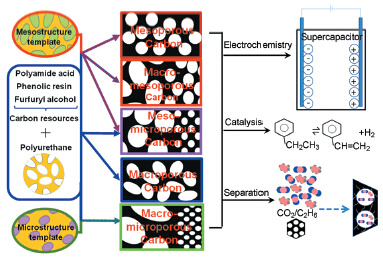

骨架状聚氨酯海绵模板导向制备多级孔碳材料

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Hierarchically Porous Carbon Materials Templated from Skeletonal Polyurethane Foam

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |