PDF(2617 KB)

PDF(2617 KB)

PDF(2617 KB)

PDF(2617 KB)

PDF(2617 KB)

PDF(2617 KB)

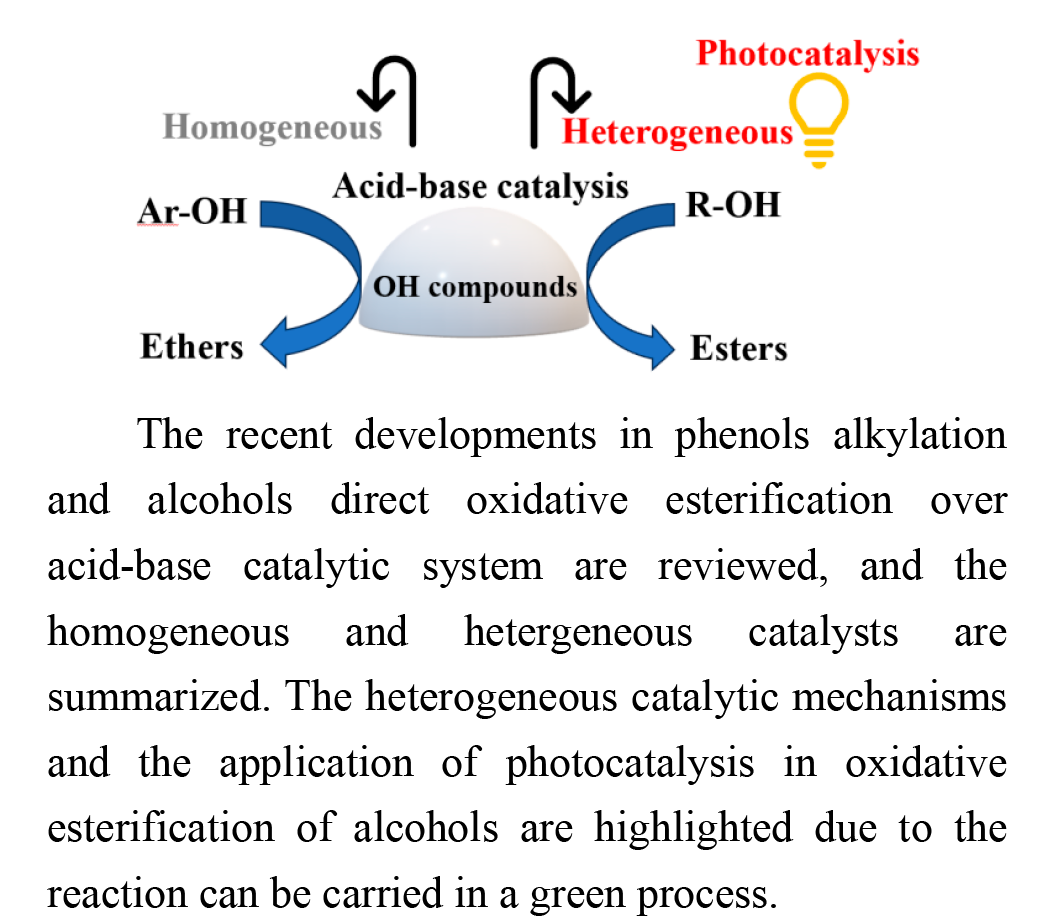

羟基化合物的催化转化研究:酚类与醇类化合物转化为醚与酯

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Catalytic Conversion of Hydroxyl Compounds : Conversion of Phenols and Alcohols to Ethers and Esters

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |