PDF(4322 KB)

PDF(4322 KB)

PDF(4322 KB)

PDF(4322 KB)

PDF(4322 KB)

PDF(4322 KB)

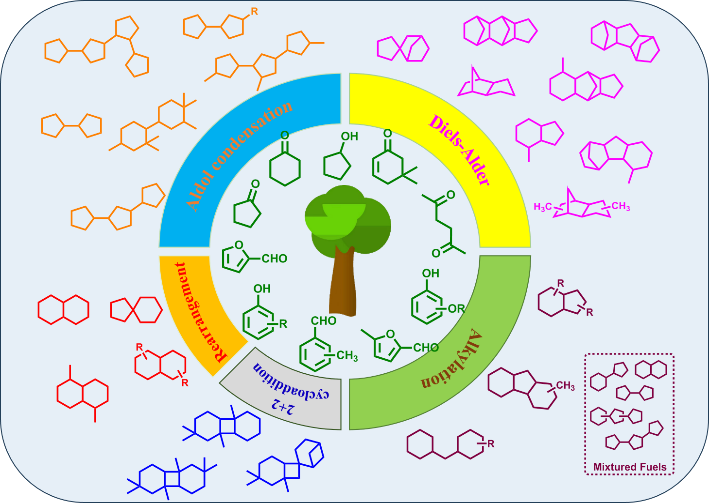

生物质多环碳氢高密度航空燃料合成

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Synthesis of Multi-Cyclic Hydrocarbon High-Density Aviation Fuels from Biomass

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |