PDF(52707 KB)

PDF(52707 KB)

PDF(52707 KB)

PDF(52707 KB)

PDF(52707 KB)

PDF(52707 KB)

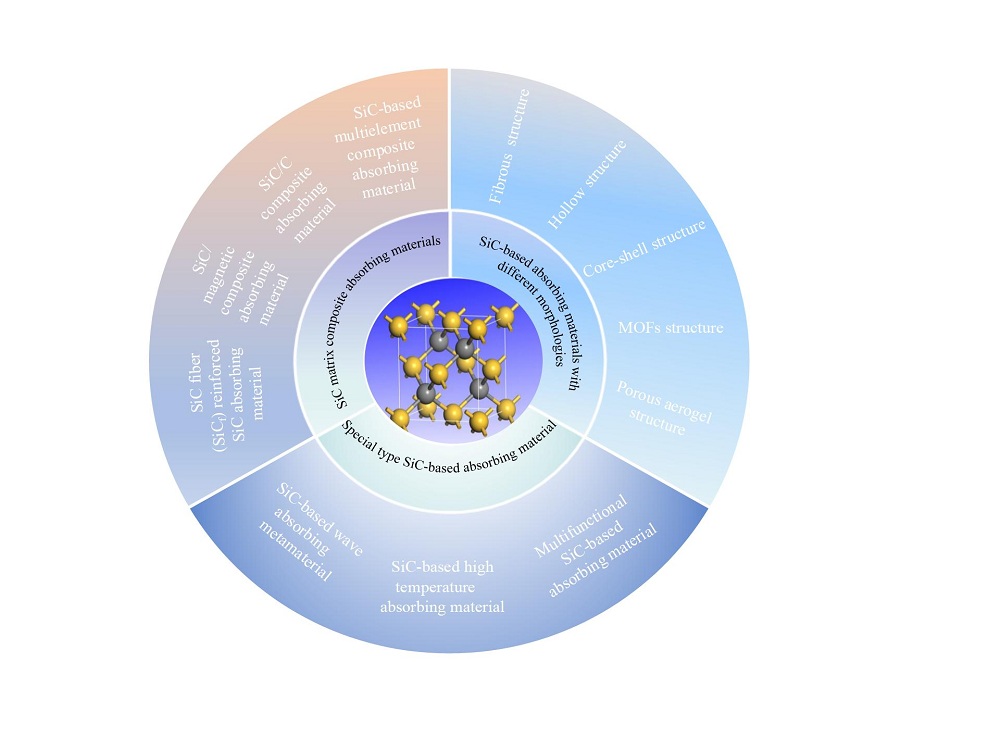

碳化硅基材料在电磁波吸收领域的研究进展

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Research Progress on Electromagnetic Wave Absorption of Silicon Carbide-Based Materials

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |