PDF(45467 KB)

PDF(45467 KB)

PDF(45467 KB)

PDF(45467 KB)

PDF(45467 KB)

PDF(45467 KB)

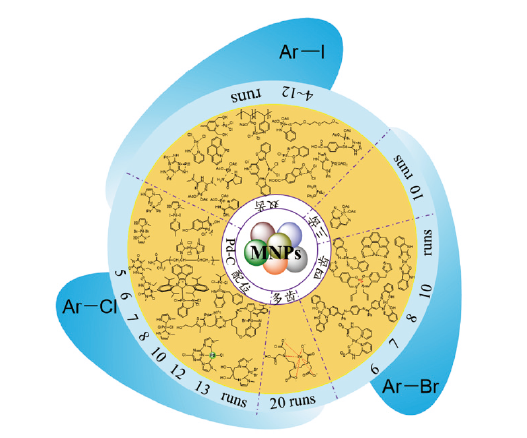

基于多齿钯化合物的磁性纳米颗粒催化材料的设计合成及应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Design, Synthesis and Application of Magnetic Nanoparticle Catalytic Materials Based on Multientate Palladium Compounds

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |