PDF(26665 KB)

PDF(26665 KB)

PDF(26665 KB)

PDF(26665 KB)

PDF(26665 KB)

PDF(26665 KB)

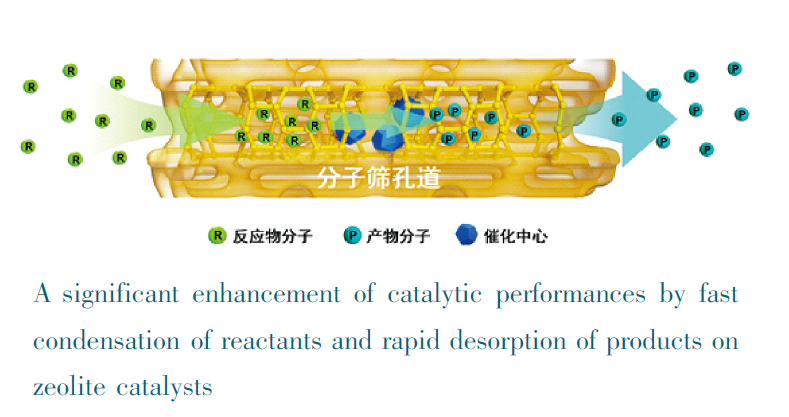

分子筛催化反应中的凝聚态化学

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Condensed Matter Chemistry in Catalysis by Zeolites

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |