PDF(8569 KB)

PDF(8569 KB)

多维度非锂无机杂化组分应用于锂电池复合聚合物电解质

马冰怡, 黄盛, 王拴紧, 肖敏, 韩东梅, 孟跃中

化学进展 ›› 2023, Vol. 35 ›› Issue (9) : 1327-1340.

PDF(8569 KB)

PDF(8569 KB)

PDF(8569 KB)

PDF(8569 KB)

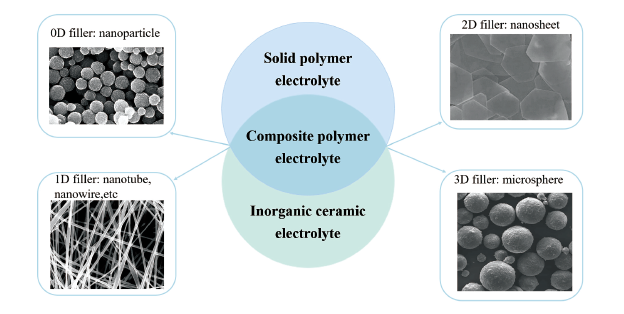

多维度非锂无机杂化组分应用于锂电池复合聚合物电解质

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Composite Polymer Electrolytes with Multi-Dimensional Non-Lithium Inorganic Hybird Components for Lithium Batteries

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |