PDF(8486 KB)

PDF(8486 KB)

PDF(8486 KB)

PDF(8486 KB)

PDF(8486 KB)

PDF(8486 KB)

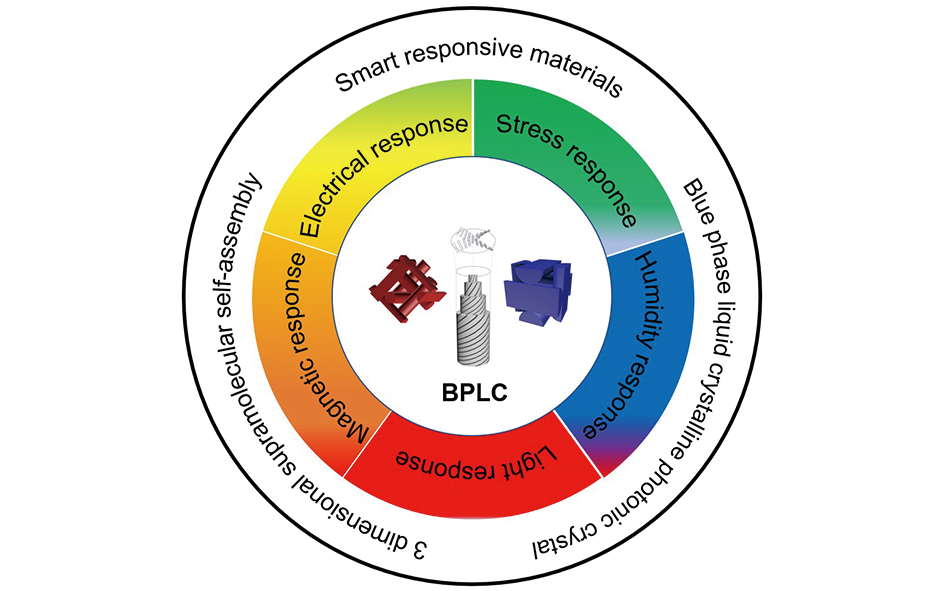

智能响应蓝相液晶光子晶体

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Stimuli-Responsive Blue Phase Liquid Crystalline Photonic Crystal

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |