PDF(2204 KB)

PDF(2204 KB)

PDF(2204 KB)

PDF(2204 KB)

PDF(2204 KB)

PDF(2204 KB)

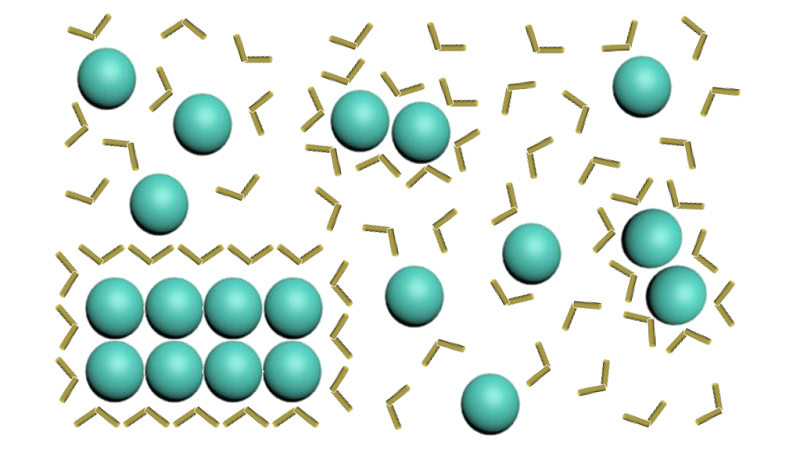

液态凝聚态调控的分散质组装及功能

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Liquid Condensed Matter Mediated Assembly and Functionality of Dispersoid

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |