PDF(9157 KB)

PDF(9157 KB)

PDF(9157 KB)

PDF(9157 KB)

PDF(9157 KB)

PDF(9157 KB)

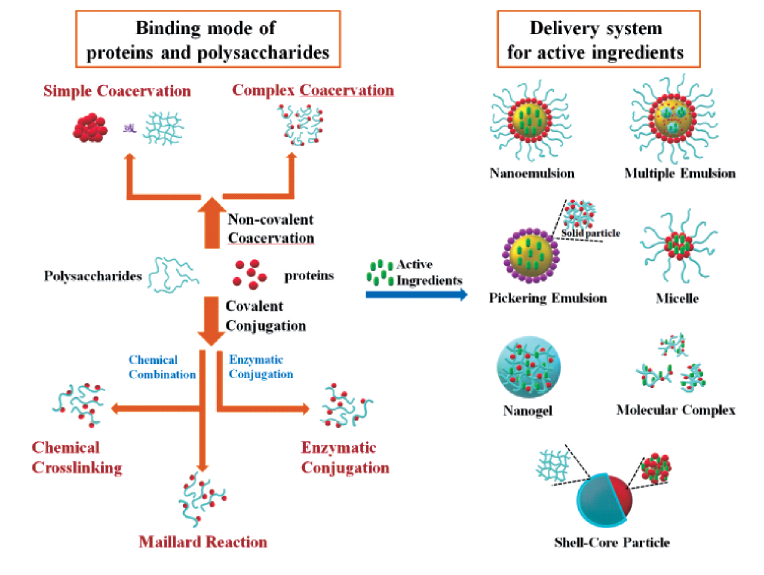

蛋白质-多糖复合体系在活性物质传递中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Application of Protein-Polysaccharide Complex System in the Delivery of Active Ingredients

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |