PDF(11629 KB)

PDF(11629 KB)

PDF(11629 KB)

PDF(11629 KB)

PDF(11629 KB)

PDF(11629 KB)

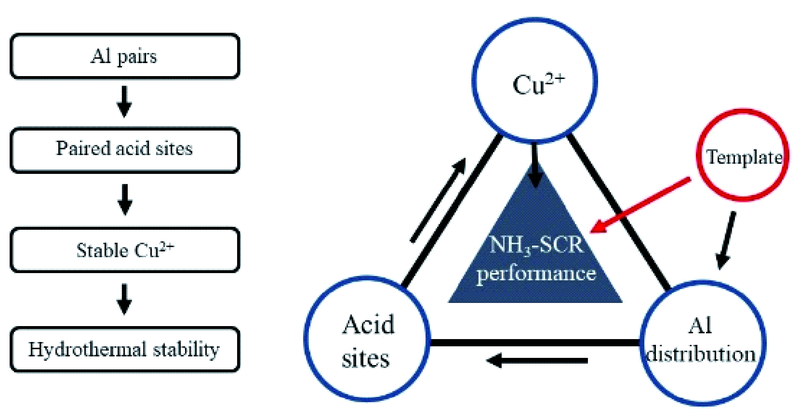

从铜离子、酸中心与铝分布的关系分析不同模板剂制备Cu-SSZ-13的NH3-SCR性能

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Relation Among Cu2+, Brønsted Acid Sites and Framework Al Distribution: NH3-SCR Performance of Cu-SSZ-13 Formed with Different Templates

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |