PDF(17888 KB)

PDF(17888 KB)

PDF(17888 KB)

PDF(17888 KB)

PDF(17888 KB)

PDF(17888 KB)

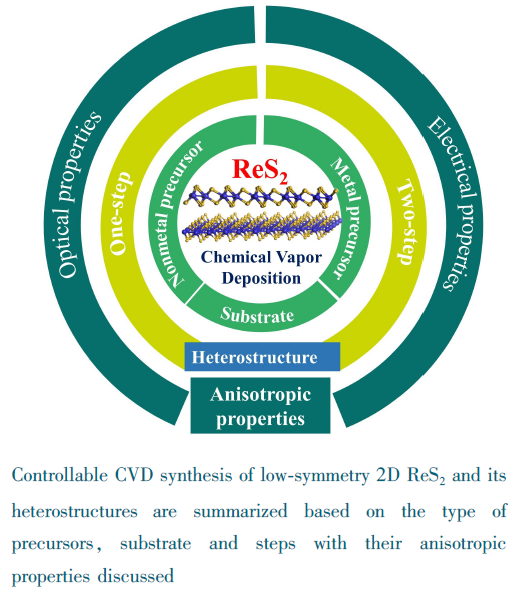

低对称性二维ReS2及其异质结的化学气相沉积法制备及性质

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Low-Symmetry Two-Dimensional ReS2 and its Heterostructures:Chemical Vapor Deposition Synthesis and Properties

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |