PDF(4421 KB)

PDF(4421 KB)

PDF(4421 KB)

PDF(4421 KB)

PDF(4421 KB)

PDF(4421 KB)

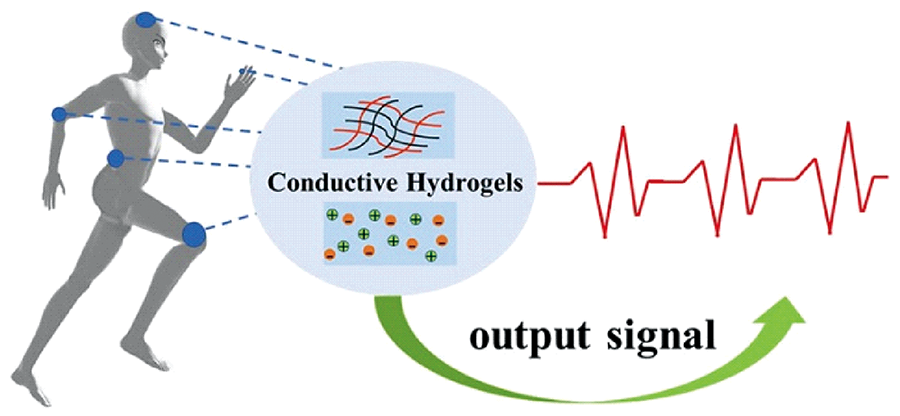

高分子导电水凝胶的制备及在柔性可穿戴电子设备中的应用

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of Polymer Conductive Hydrogel and Its Application in Flexible Wearable Electronic Devices

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |