PDF(11992 KB)

PDF(11992 KB)

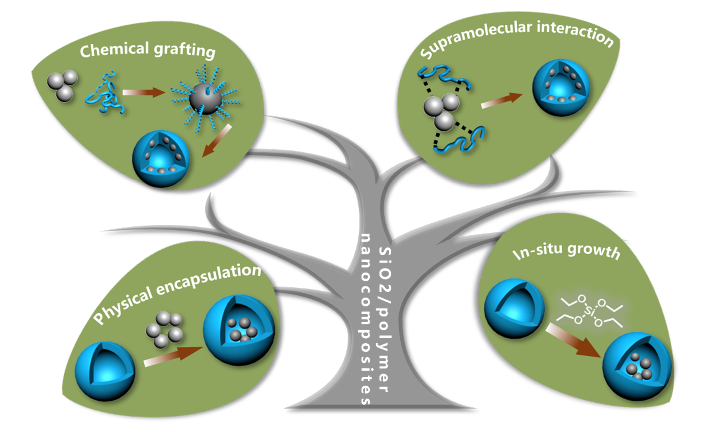

基于聚合诱导自组装制备二氧化硅/聚合物纳米复合材料

冯业娜, 刘书河, 张书博, 薛彤, 庄鸿麟, 冯岸超

化学进展 ›› 2021, Vol. 33 ›› Issue (11) : 1953-1963.

PDF(11992 KB)

PDF(11992 KB)

PDF(11992 KB)

PDF(11992 KB)

基于聚合诱导自组装制备二氧化硅/聚合物纳米复合材料

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Preparation of SiO2/Polymer Nanocomposites Based on Polymerization-Induced Self-Assembly

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |